PTC Integrated sensor

A technology that integrates sensors, sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

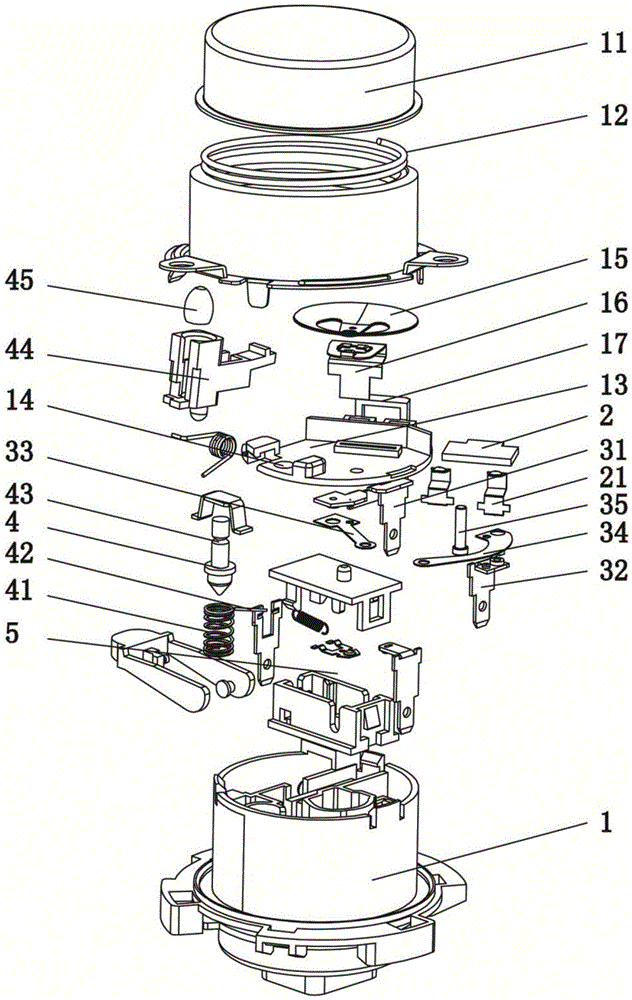

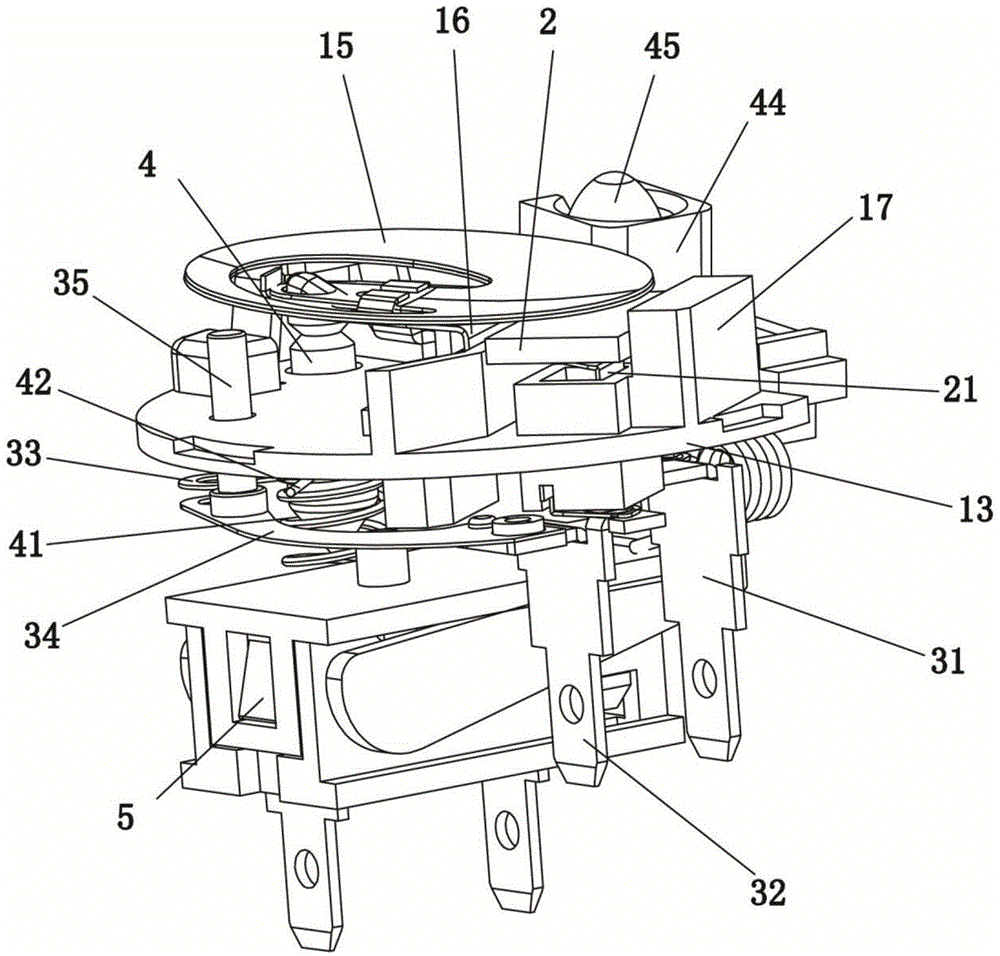

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-2 As shown, a kind of PTC integrated sensor described in the present invention comprises base 1, and sensor component is arranged in base 1, and the upper end of described base 1 is provided with the loam cake 11 that moves independently relatively with it, and base 1 and loam cake 11 is provided with a compression spring 12, and the upper cover 11 is in contact with the sensing part in the base 1 during the downward stroke; ; The heat holding device includes a PTC heating source 2, which is provided with two positive and negative electrodes 21, the PTC heating source 2 and the upper cover 11 are set in cooperation and the PTC heating source 2 is connected to the overheated electrode 21 by the PTC heating source 2. The power-off device is connected in parallel; the PTC integrated sensor is loaded on the liquid heater, and when the inner pot is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com