Air duct model clamping tool for diesel locomotive ventilation experiment

A technology for internal combustion locomotives and clamping tooling, applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of high cost, long experiment cycle, inflexible use of air duct model test bench, etc., achieve simple and convenient use, and improve applicability Sexuality, the effect of shortening the experimental cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

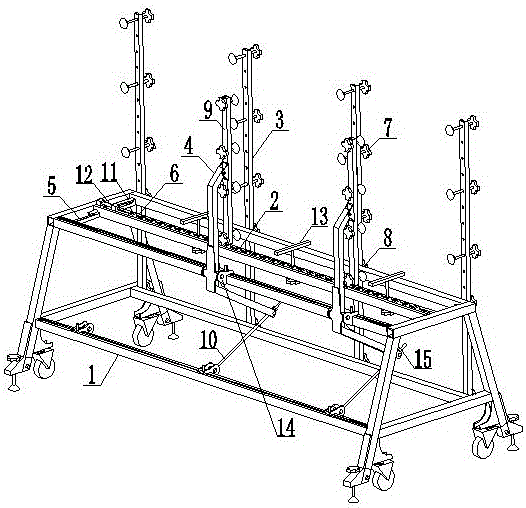

[0015] Such as figure 1 It is a structural schematic diagram of the present invention, an air duct model clamping tool for a diesel locomotive ventilation experiment, including a base 1, a center beam 2, a front bracket 3 and a rear bracket 4, the center beam 2 is installed on the top of the base 1, and the front bracket 3 and the rear support 4 are respectively connected to both sides of the base 1, the beam of the base 1 is a groove track structure, the end beam is provided with a guide rail 5, the middle beam 2 is embedded with a support plate 6, and the front support 3 is provided with a clamp bar 7 and positioning bolt 8, rear support 4 is provided with compression arm 9 and leading screw 10, and compression arm 9 is also provided with clamp bar 7. The two ends of the center beam 2 are slidably erected on the guide rail 5, and adjusted and positioned by the longitudinal bolts 11. The support plate 6 is slidably connected in the middle beam 2, and is adjusted and position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com