Regular-tetrahedron-based self-reconfigurable robot unit module mechanism

A technology of unit modules and regular tetrahedrons, applied in the field of robotics, can solve problems such as inability to realize deformation forms, motion modes, and configuration restrictions, and achieve the effects of low overall processing costs, reduced complexity, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

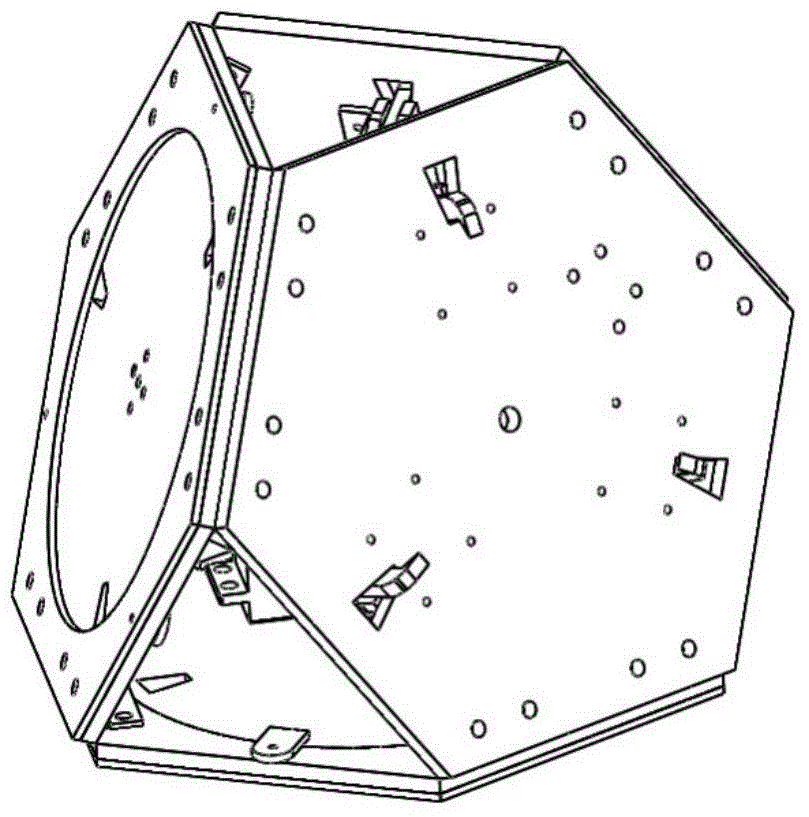

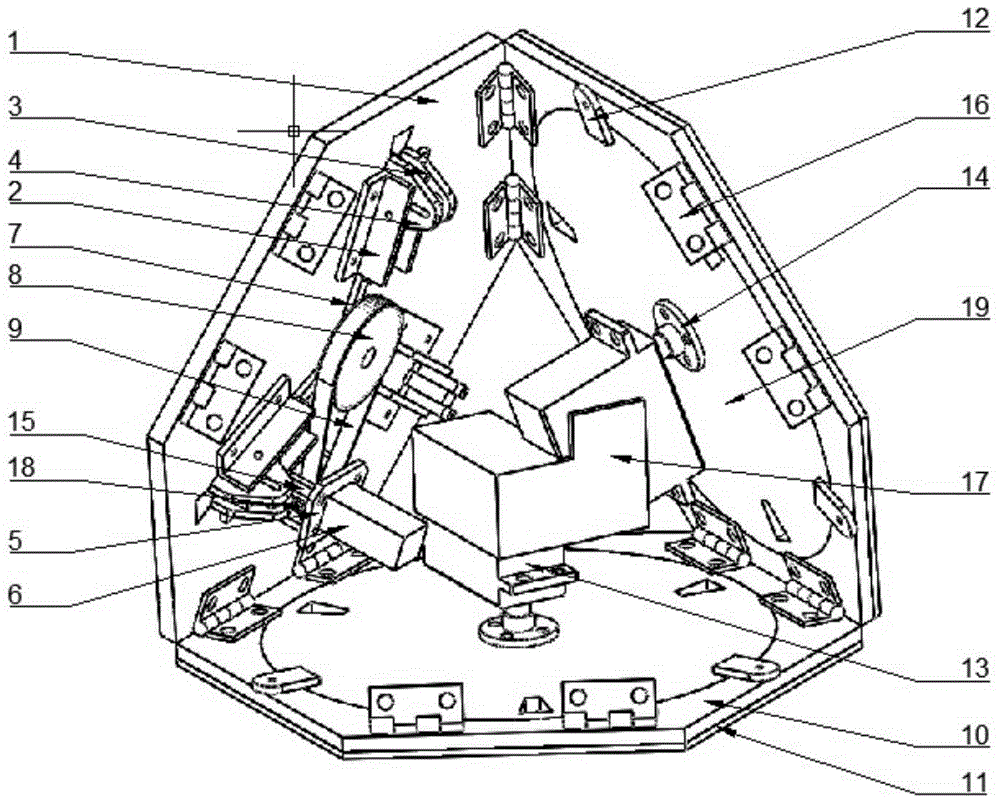

[0030] Such as figure 1 and figure 2 As shown, it is the unit module mechanism of this embodiment, including: four docking surface mechanisms fixedly connected to each other, wherein: at least one of the four docking surface structures is an active docking surface mechanism, and at least one is a passive docking surface mechanism, wherein: The active docking surface mechanism is provided with a movable docking device, and the passive docking surface mechanism is provided with a rotating device in contact with the movable docking device.

[0031] Such as figure 2 As shown, the butt surface mechanisms are connected by hinges 16 .

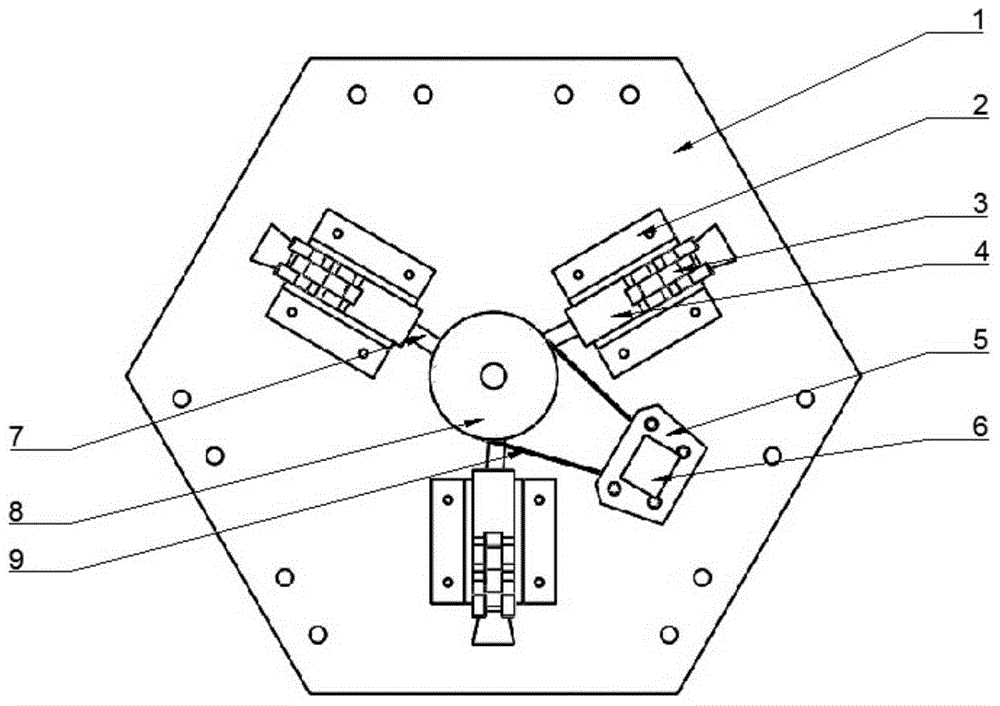

[0032] Such as image 3 As shown, the movable docking device includes: at least one set of fixing mechanisms and a driving mechanism connected thereto, wherein: the driving mechanism drives the fixing mechanism to connect or release with the rotating device.

[0033] The fixing mechanism in this embodiment includes: angle iron 2, docking claw 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com