Integral hoisting technology of ship superstructure

A superstructure and overall hoisting technology, applied in the direction of superstructure, ship construction, ship parts, etc., can solve the problems such as poor effect, and achieve the effect of improving the pre-outfitting rate and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

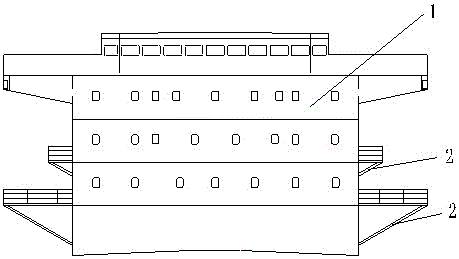

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The overall hoisting process of the ship superstructure of the present invention comprises the following steps:

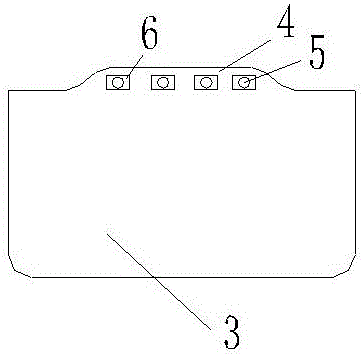

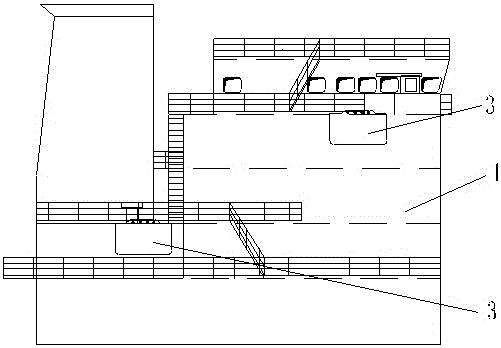

[0021] A. The superstructure 1 is assembled near the wharf. At the same time, the internal and external structure of the superstructure 1 is strengthened, and the margin is cut according to the actual situation before hoisting, and there is no margin to board the ship;

[0022] B. Install positioning eye rings at the lower openings of the front and rear end wall corners of the assembled superstructure 1. There are three positioning eye rings, two in front and one in back or two in back and one in front;

[0023] C. Mark and assemble the outline of the bottom layer of the superstructure 1 on the deck of the berth, and install and weld positioning pins at the corresponding corners of the front and rear end walls;

[0024] D....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com