Method for improving advanced outfitting rate of ship cable

A pre-outfitting and cable technology, applied in cable laying equipment, ships, etc., can solve the problems of long distance between equipment, complex structure, affecting the pre-outfitting rate of ships' cables, etc., and achieve the effect of improving the pre-outfitting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

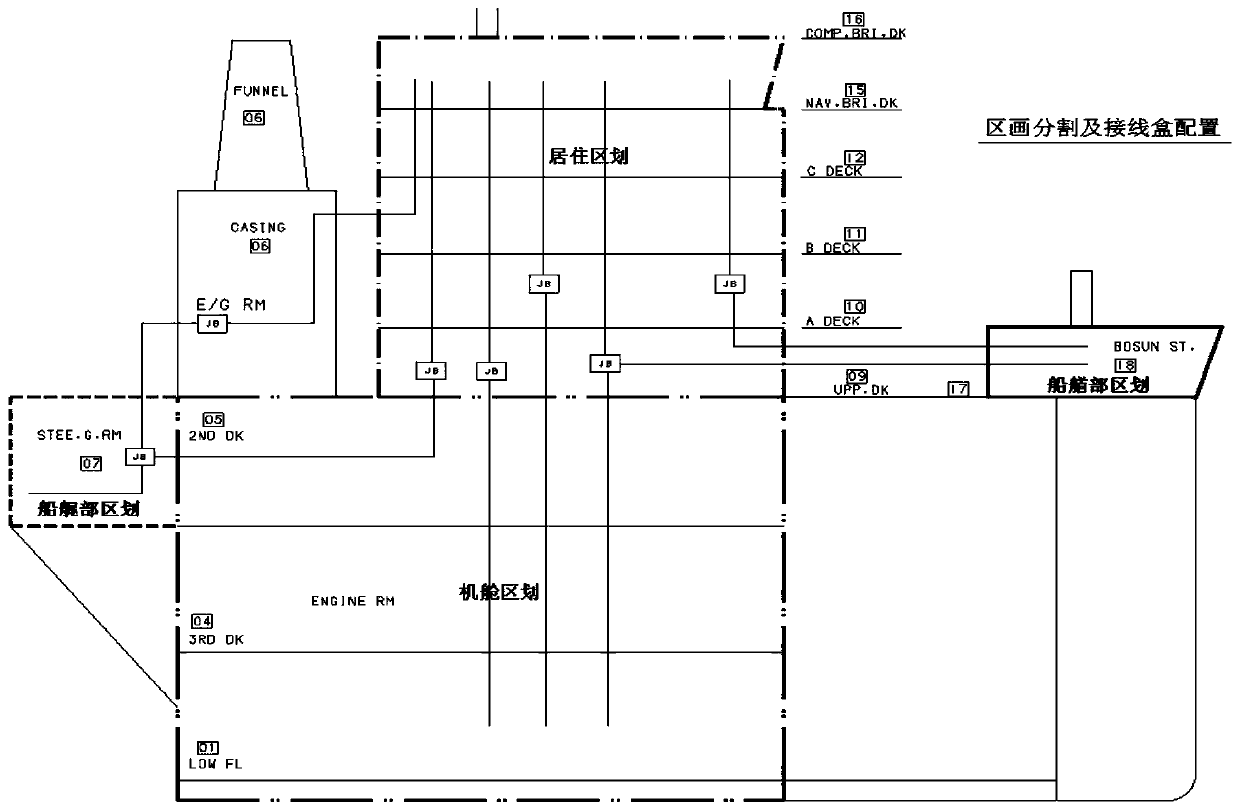

[0019] see figure 1 , first lay the cable in the engine room area and the residential area, and then cut off the cable at the junction of the two, and set the junction box JB at the receiving point, and then lay the engine room area first, and the residential area after the laying, the two cables are connected After laying in place, connect at the junction box JB, which can not only solve the problem of loading sequence, but also not affect the electrical performance. Similarly, between the engine room division and the bow division, and between the living division and the bow are also realized in the same way.

[0020] In this embodiment, the setting of junction boxes in other places will be reasonably set according to the actual configuration of the system diagram, and there is no fixed rule.

[0021] In this embodiment, the cut cables are marked to prevent unintentional contact with the cables during the construction process, resulting in the failure of the cables to be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com