Passive shaft device of bag turner with circuit channel and air system and method of use thereof

A gas circuit system and circuit channel technology, which is applied in the field of the passive shaft device of the bale turning machine, can solve the problems such as the inability to set up a spare gas circuit, the cables are easily scratched, and the installation and maintenance are difficult, so as to improve the core competitiveness and improve the utilization rate. rate and safety, and the effect of reducing accident rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

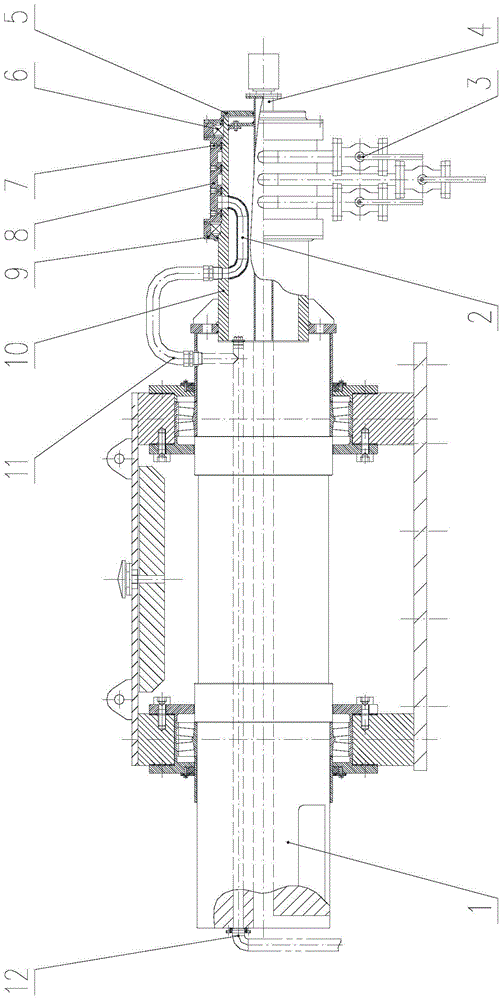

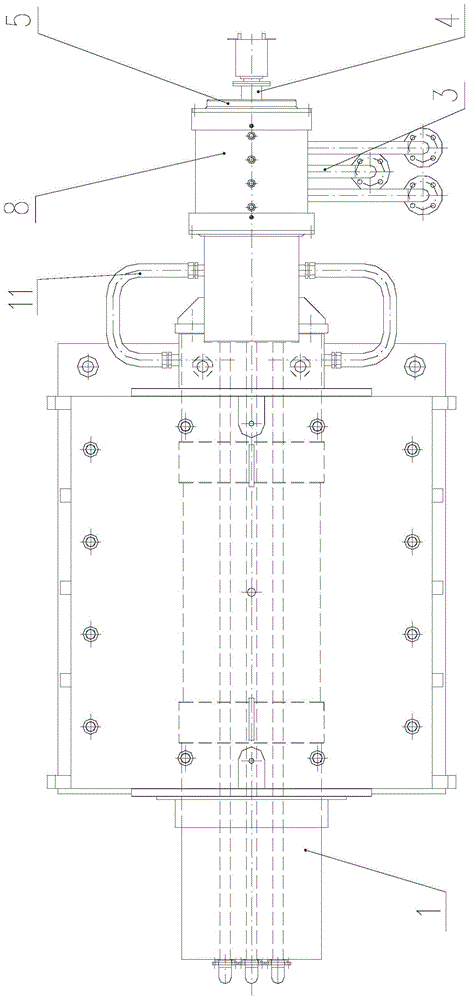

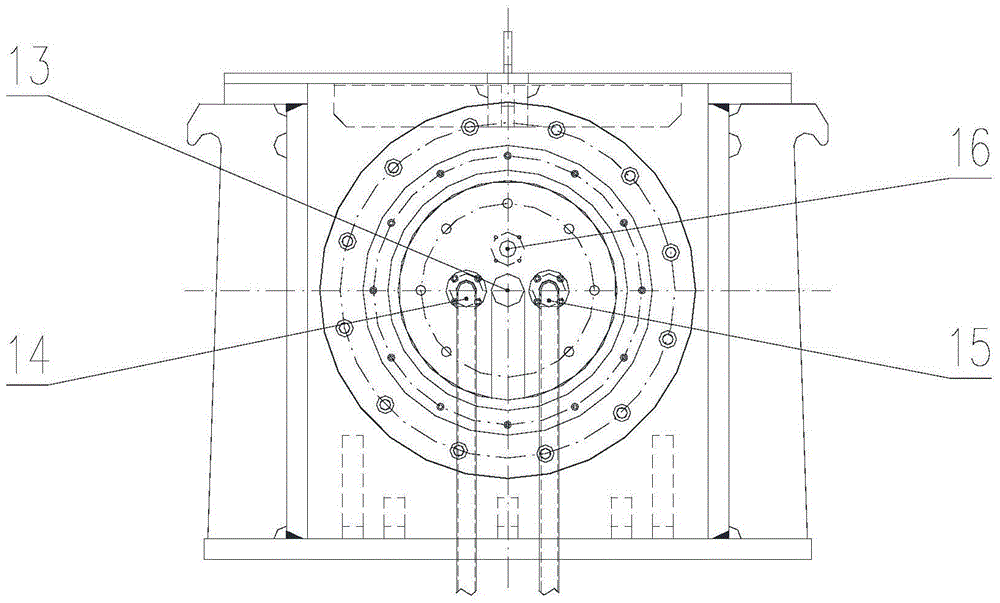

[0030] Such as Figure 1-Figure 3 As shown, a passive shaft device of a turn-over machine with a circuit channel and a gas path system includes: a passive shaft 1 and an air outlet device 12; the shaft center of the passive shaft 1 is provided with an opening as a cable channel 13, and the other three are provided in the axial direction. The two openings are used as the air inlet pipe 14, the air outlet pipe 15 and the spare pneumatic pipe 16. The passive shaft 1 is fixed with an air outlet device 12 at one end, and connected to the shaft 10 by bolts at the other end. There is a jacket 8 and a deep groove ball bearing 6, which can be quickly replaced by replacing the access point of the manual ball valve 3 at the gas inlet and the access point of the corresponding air outlet device 12. The spare pneumatic pipeline 16 is not the same during normal operation. The outlet device 12 is connected. When the inlet pipe 14 or the outlet pipe 15 is damaged and cannot be used, change the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com