The shelter roll around the axis, the method of a low tension roll around the sheet, and the piston seal structure used in the implementation method

A technology for winding shafts and sheets, which is applied in the direction of winding strips, piston rings, thin material processing, etc., and can solve problems such as changes in support positions and complicated structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

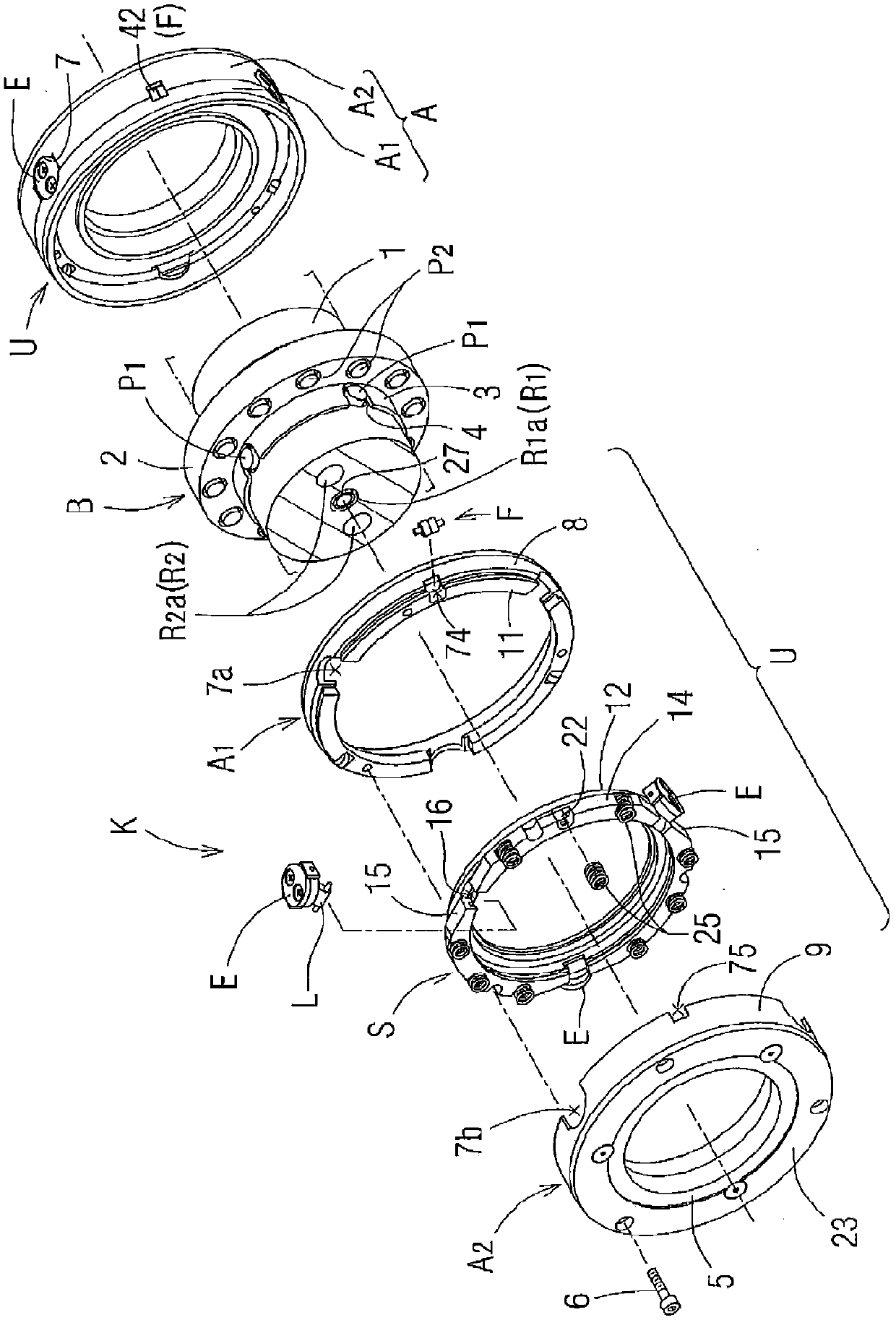

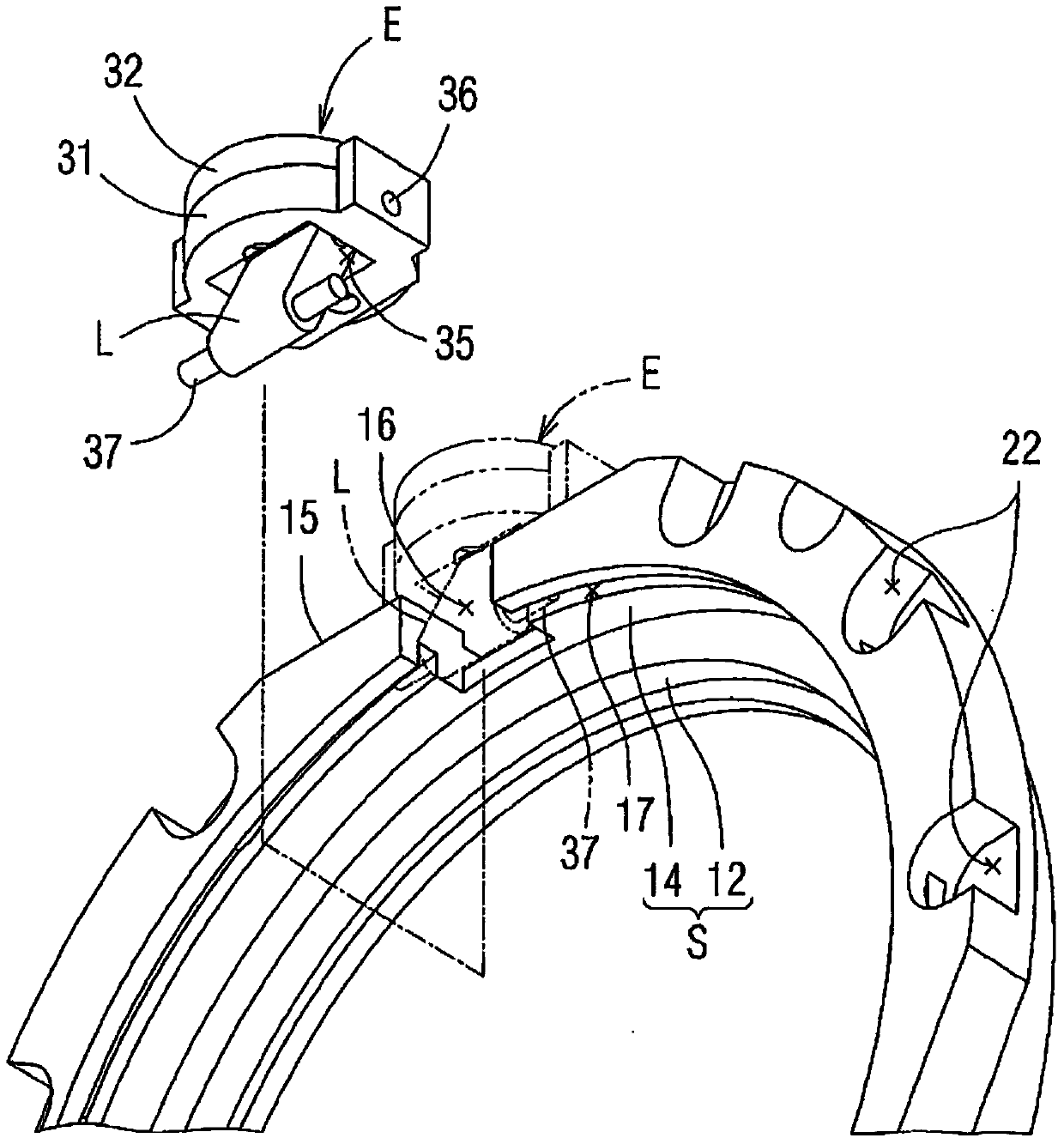

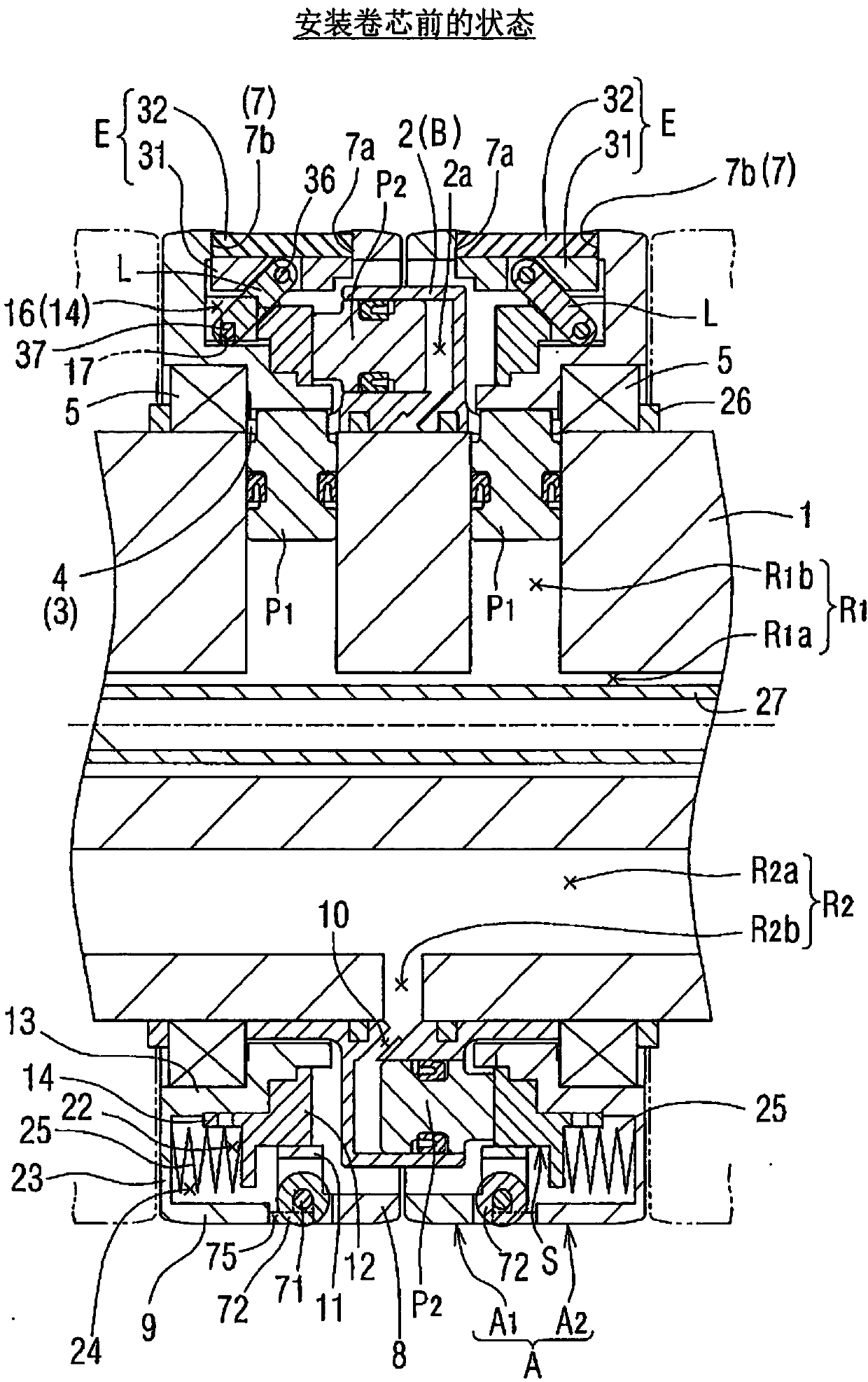

[0071] The present invention will be described in more detail below with a number of the most excellent examples. First refer to Figure 1 to Figure 7 The winding shaft K will be described. The winding shaft K is configured by attaching a plurality of winding units U to a shaft core 1, and a first passage R1 of compressed air for applying a pressing force to a first piston P1 to be described later is formed on the shaft core 1, and a first passage R1 for pressurized air to be described later is formed on the shaft core 1. The second piston P2 applies pushing force to the second channel R2 of compressed air. Such as Figure 3 ~ Figure 7 As shown, the first passage R1 includes an axial passage R1a and a plurality of radial passages R1b, the axial passage R1a is formed in the axial direction at the center of the shaft core 1, and the radial passage R1b communicates with the axial passage R1a And it is formed along the radial direction on the portion where the first piston P1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com