Connecting rod combination structure for trolley

A connecting rod and trolley technology, which is applied in the field of connecting rod binding structures for trolleys, can solve the problems of broken elastic clips, falling off of locking protrusions, difficulty in pulling out and inserting connecting rods, etc., so as to reduce the resistance of insertion and extraction. , Improve the effect of supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

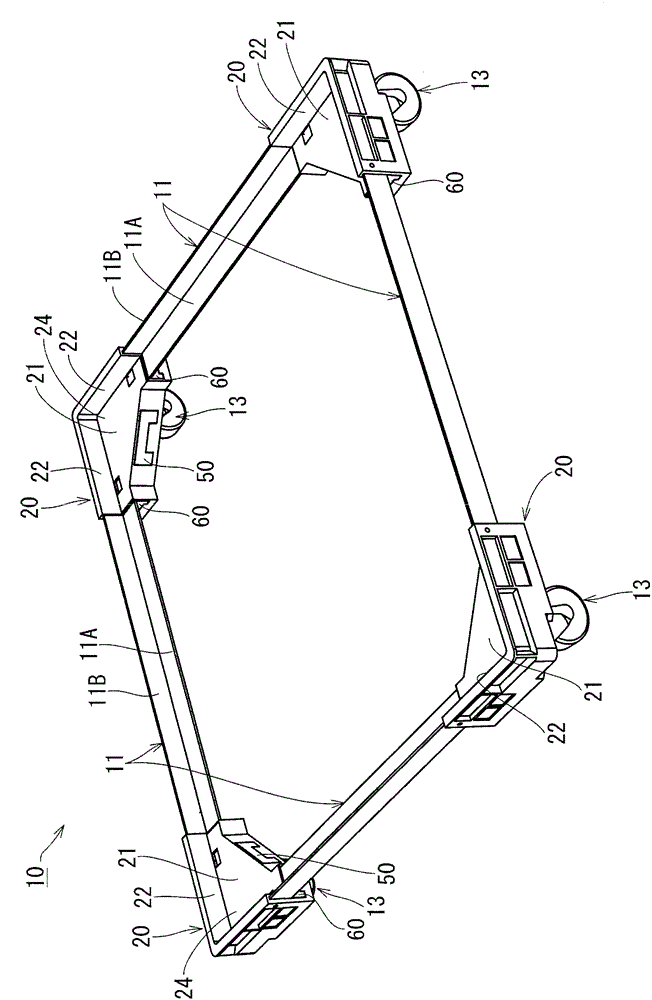

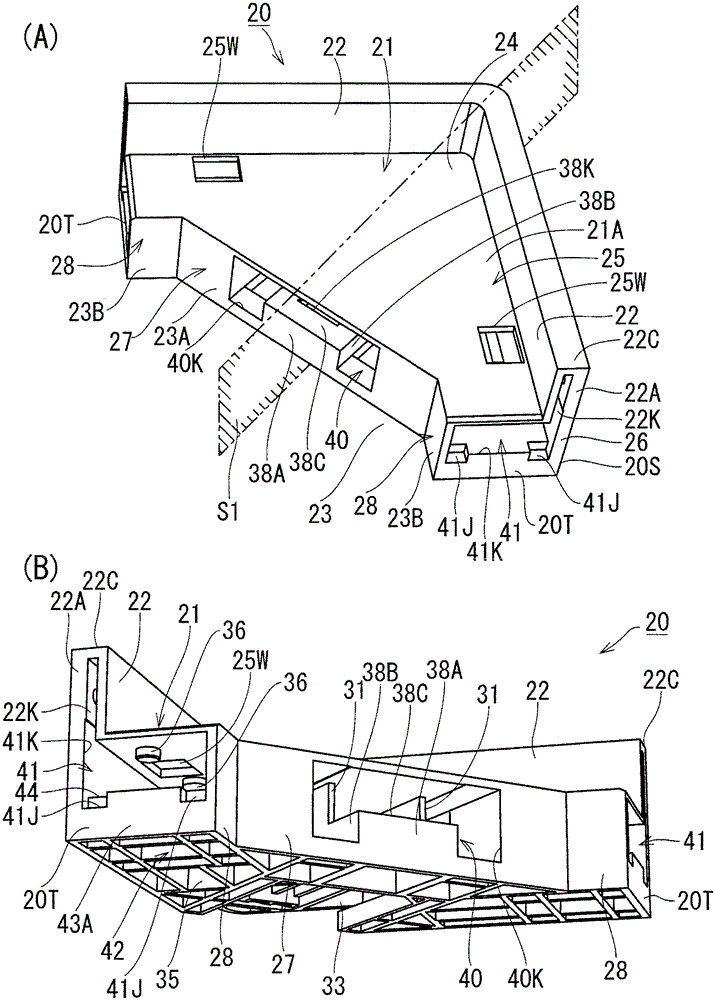

[0068] Below, based on Figure 1 to Figure 13 The first embodiment of the present invention will be described. figure 1 The trolley 10 shown has a quadrangular frame shape in plan view, and the trolley coupling structure of the present invention is used to connect the connecting rods 11 extending along the four sides and the support blocks 20 supporting the casters 13 at the four corners.

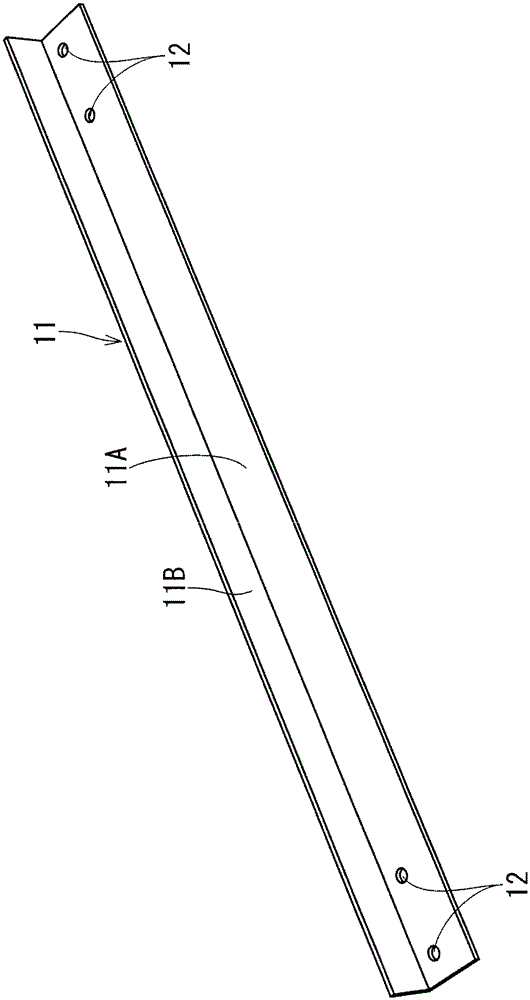

[0069] The connecting rod 11 is, for example, a so-called angle iron made of aluminum and has an L-shaped cross-section. A vertical plate portion 11B constituting a longitudinal side portion of the L-shape stands upright above a horizontal plate portion 11A constituting a lateral side portion. Such as figure 2 As shown, a pair of connecting through-holes 12 , 12 are respectively formed at both ends of the horizontal plate portion 11A of the connecting rod 11 . These connecting through-holes 12 , 12 are all circular holes arranged along the longitudinal direction of the connecting rod 11 ...

no. 2 approach

[0108] This embodiment is shown in Figure 14 ~ Figure 19 , is a structure in which the rod stopper 60 can be inserted into the rod insertion hole 41 from a direction different from that of the connecting rod 11 . That is, if Figure 14 As shown in (B), rod stopper insertion holes 46 , 46 communicating with the rod insertion hole 41 are respectively formed in the main side walls 26 , 26 of the support block 20V of this embodiment. The rod stopper insertion hole 46 has a horizontally long quadrangular shape as a whole, and has stepped recesses 46J, 46J sunken in steps at both ends of the lower portion of the opening. In addition, the rod stopper insertion hole 46 is located at a position below which the plate thickness of the rod 11 is connected with respect to the inner upper surface of the rod insertion hole 41 . The inner lower surface of the rod stopper insertion hole 46 excluding the step recesses 46J, 46J is flush with the inner lower surface of the rod insertion hole 4...

no. 3 approach

[0118] This embodiment is shown in Figure 20 ~ Figure 25 . The support block 20W of this embodiment is as Figure 20 ~ Figure 22 As shown, the caster stopper receiving portion 40W and the rod insertion holes 41, 41 are communicated in a wide range, and the caster stopper 50W is used as the caster stopper 50 and the rod stopper 60 of the first embodiment. , 60 structure. Specifically, as Figure 20 as well as Figure 21 As shown, the inner corner side walls 28 , 28 remain slightly in the form of columns on one side of the block front end faces 20T, 20T. Additionally, if Figure 22 As shown, the plate side support ribs 29B, 29B are cut out to the position in front of the communication hole 37 on the back side of the caster stopper storage part 40W than the insertion opening 40N of the caster stopper 50W in the caster stopper storage part 40W. .

[0119] In contrast, such as Figure 24 (A) and Figure 24 As shown in (B), the caster stopper 50W is formed in a structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com