Gantry crane having main beam with suspension cable type structure

A technology of gantry cranes and cranes, which is applied in the direction of cable cranes, cranes, support structures, etc., can solve the problems of low bending and torsional strength of the main girder, large shear stress, and large deflection of the main girder, so as to reduce weight and increase bearing capacity , to ensure the effect of the overall bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

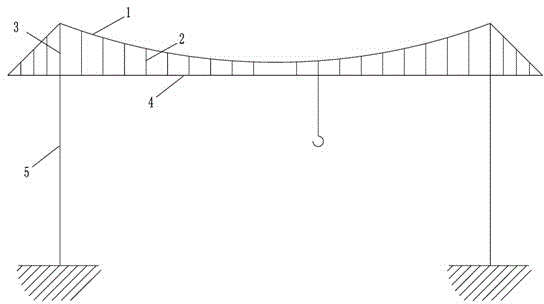

[0029] Such as figure 1 As shown, a main girder gantry crane with a suspension cable structure includes a lifting trolley, a traveling mechanism of the lifting trolley, a traveling mechanism of the gantry crane, a control system, outriggers and a main beam. Cable structure, the harp suspension cable structure includes box girder 4, suspension cable 1, suspension cable 2 and cable tower 3, cable tower 3 is fixed at the supporting point of outrigger 5 on the box beam 4, and suspension cable 1 is located on the box girder Above 4, the suspension cable 1 passes through the top of the cable tower 3 and the two ends of the suspension cable 1 are anchored on the anchor seats at the two ends of the box beam 4, and the suspension cable 2 is installed vertically between the suspension cable 1 and the box beam 4 and hangs The lower end of the cable 2 is installed with a pre-tightening nut. During installation and commissioning, the pre-tightening force is generated by tightening the pre-...

Embodiment 2

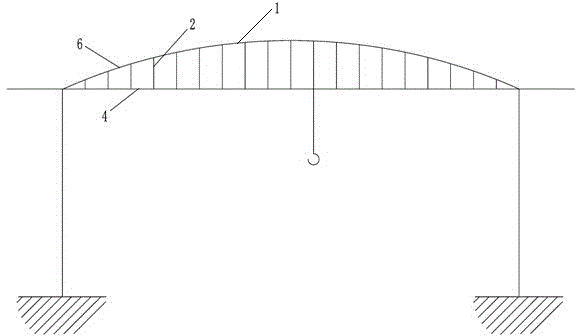

[0033] Such as figure 2As shown, a main girder gantry crane with a suspension cable structure includes a lifting trolley, a traveling mechanism of a lifting trolley, a traveling mechanism of a gantry crane, a control system, outriggers and a main beam. The main beam is a back cable with low ends and a high middle. Arched style suspension cable structure, the back cable arched style suspension cable structure includes box girder 4, suspension cable 1, sling 2 and arched beam 6, and the two ends of arched beam 6 are fixed on the support on box girder 4 At the supporting point of the leg 5, the suspension cable 1 is installed on the back of the arched beam 6, the suspension cable 1 is located above the box beam 4 and the two ends of the suspension cable 1 are fixedly connected with the two ends of the box beam 4, and the suspension cable 2 is vertical Installed between the suspension cable 1 and the box girder 4 and the lower end of the suspension cable 2 is installed with a pre...

Embodiment 3

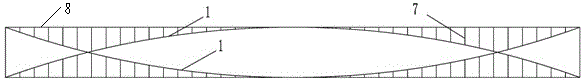

[0037] A main girder gantry crane with a suspension cable structure, including a lifting trolley, a traveling mechanism of the lifting trolley, a traveling mechanism of the gantry crane, a control system, outriggers and a main girder, the main girder is an X-curve suspension cable structure, and the X-curve suspension cable structure It includes a box beam 4, a suspension cable 1 and a suspension cable 2. There are two suspension cables 1 and the suspension cable 1 is located in a horizontal fixed frame 8, and a plurality of transverse struts 7 are arranged between the suspension cable 1 and the fixed frame 8. An adjusting nut is provided on the strut 7, and the adjusting nut controls the distance between the two suspension cables 1 by adjusting the length of the transverse strut 7, so that the two suspension cables 1 form an X shape in the horizontal plane, and the two suspension cables 1 in the X shape The cable 1 can provide lateral tension, thereby increasing the lateral st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com