Preparation method and application of chain transfer near-infrared dye and polymer emulsion thereof

A near-infrared dye and infrared dye technology are applied in the field of chain transfer near-infrared dyes and the preparation of polymer emulsions, which can solve the problems of reduced product contrast, uneven dispersion of infrared dyes, and insufficiently uniform dispersion of dyes, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0065] Example 1 Synthesis of near-infrared dyes using 1,6-hexanedithiol as chain transfer reagent and preparation of polymerized heat-sensitive polymer emulsion

[0066] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0067] Add 6 grams of near-infrared dye, 5.96 grams of 1,6-hexanedithiol and 4 grams of triethylamine into a single-port bottle, wherein, near-infrared dye: 1,6-hexanedithiol: triethylamine (molar ratio) 1 :5:5, add 50 ml of N,N dimethylformamide, stir and mix and react at 25°C under nitrogen protection for 24 hours. Centrifuge at a speed of 1 / min and collect the solid dye after drying.

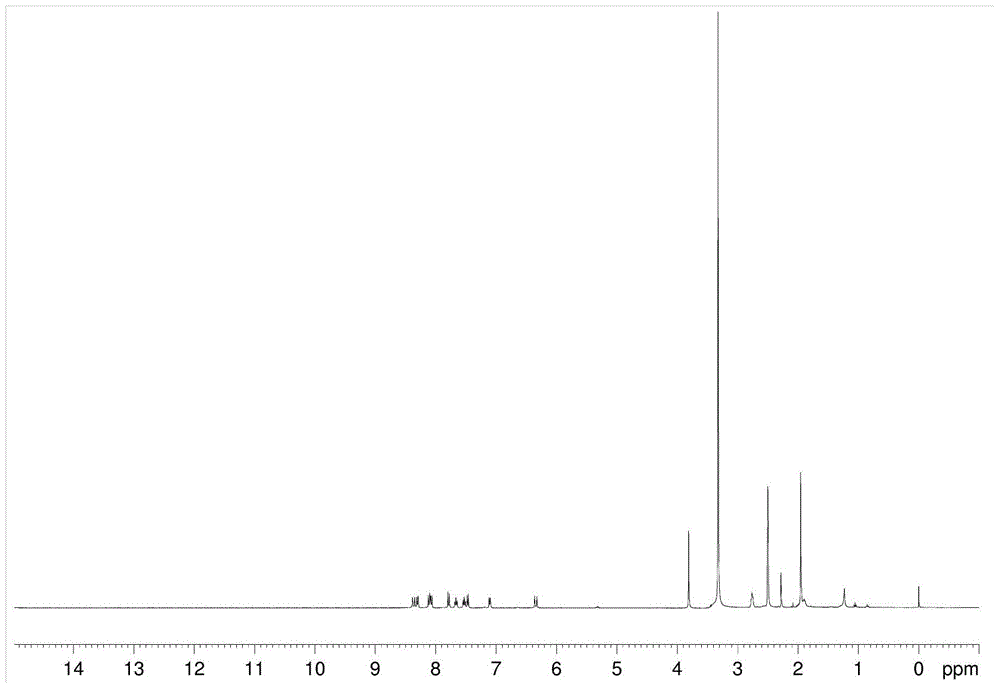

[0068] Such as figure 2 Shown is the NMR image of the chain-transferable infrared dye of Example 1.

[0069] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0070]

[0071] (2) Preparation of polymerized thermosensitive polymer emulsion

[0072] The oil phase is prepared by dissolving 5 grams of the ab...

Embodiment 21

[0081] Example 2 Synthesis of near-infrared dyes using 1,2-ethanedithiol as a chain transfer agent and preparation of polymerized thermosensitive polymer emulsion

[0082] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0083] Add 6 grams of near-infrared dye, 7.47 grams of 1,2-hexanedithiol and 8 grams of triethylamine into a single-port bottle, wherein, near-infrared dye: 1,2-ethanedithiol: triethylamine (molar ratio) 1 :10:10, add 50 milliliters of N,N dimethylformamide, stir and mix and react for 12 hours under nitrogen protection at 25°C, after the end, add a large amount of ether to the flask for stirring and washing. Centrifuge at a speed of 1 / min and collect the solid dye after drying.

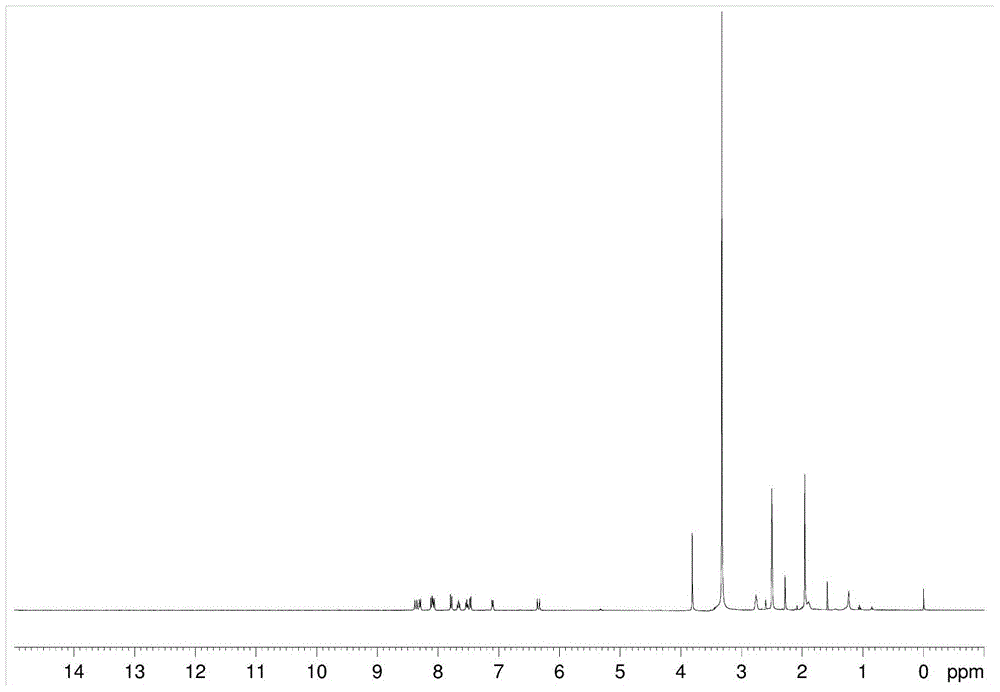

[0084] Such as image 3 Shown is the NMR map of the chain-transferable infrared dye of Example 2.

[0085] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0086]

[0087] (2) Preparation of polymerized thermosen...

Embodiment 3

[0092] Example 3 Synthesis of near-infrared dyes using 2,3 dimercaptosuccinic acid as chain transfer reagent and preparation of polymerized heat-sensitive polymer emulsion

[0093] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0094] Add 6 grams of near-infrared dye, 2.15 grams of 2,3 dimercaptosuccinic acid and 0.6 grams of triethylamine into a one-mouth bottle, wherein, near-infrared dye: 2,3 dimercaptosuccinic acid: triethylamine (molar ratio) 1:1.5:1.5, add 50 ml of N,N dimethylformamide, stir and mix and react at 25°C under nitrogen protection for 24 hours. Centrifuge at a speed of 1 rpm, and collect the solid dye after drying.

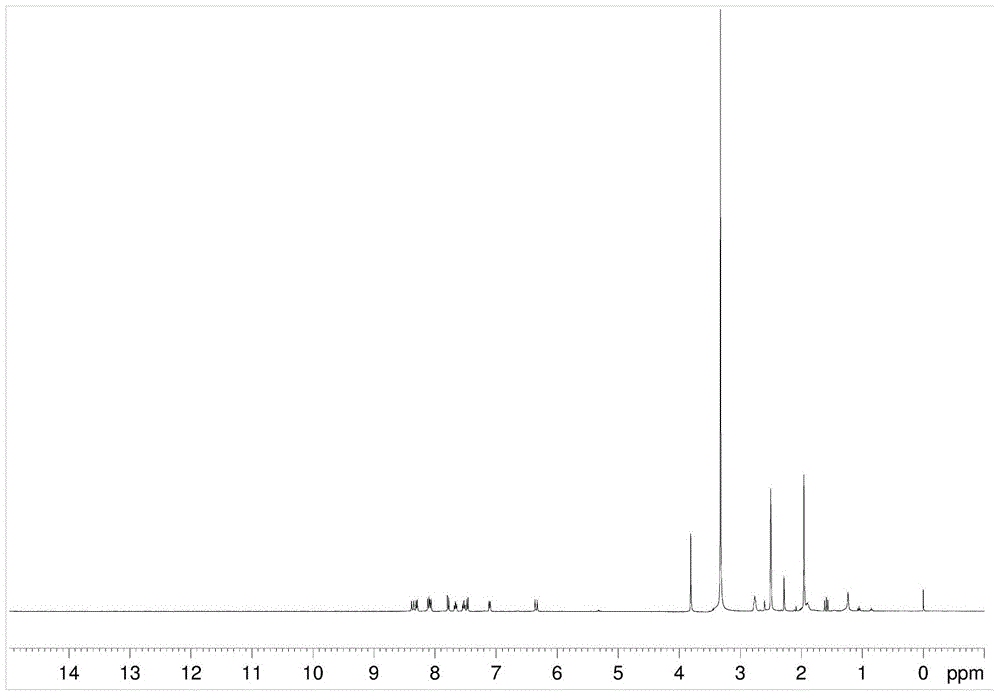

[0095] Such as Figure 4 Shown is the NMR image of the chain transfer infrared dye of Example 3.

[0096] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0097]

[0098] (2) Preparation of polymerized thermosensitive polymer emulsion

[0099] Prepare the oil phase, diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com