a turbulent roller

A turbulent flow and roller core technology, applied in the field of turbulent flow rollers, can solve the problems of weakening the adjustment effect of dilution water, insufficient stability of pulp flow, and affecting the evenness of paper sheets, etc., and achieves the advantages of easy disassembly and replacement of parts, small size, and increased lateral distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

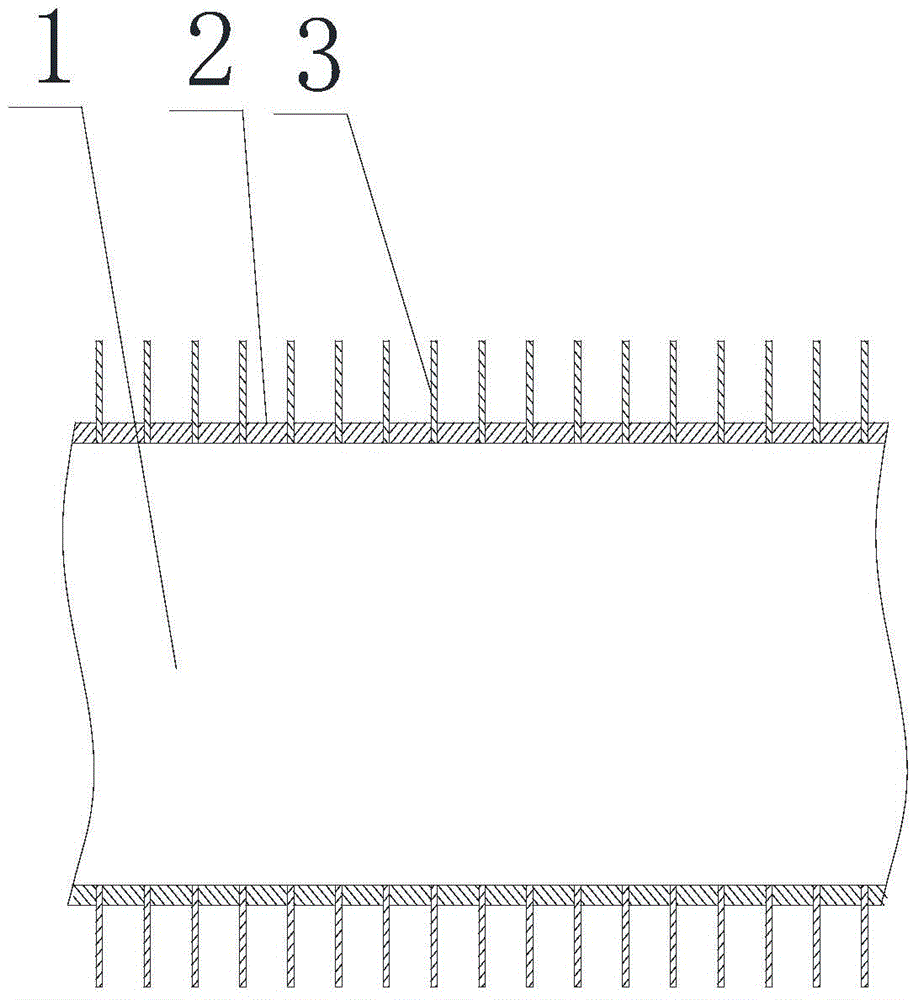

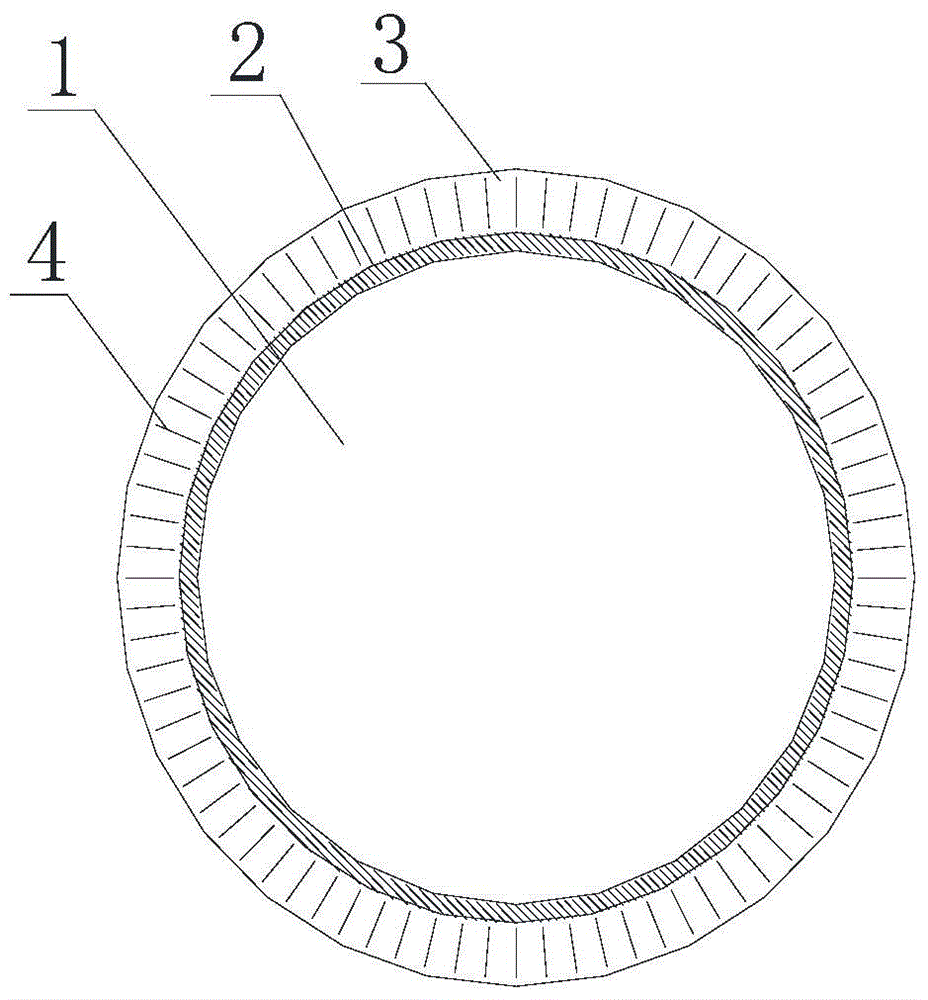

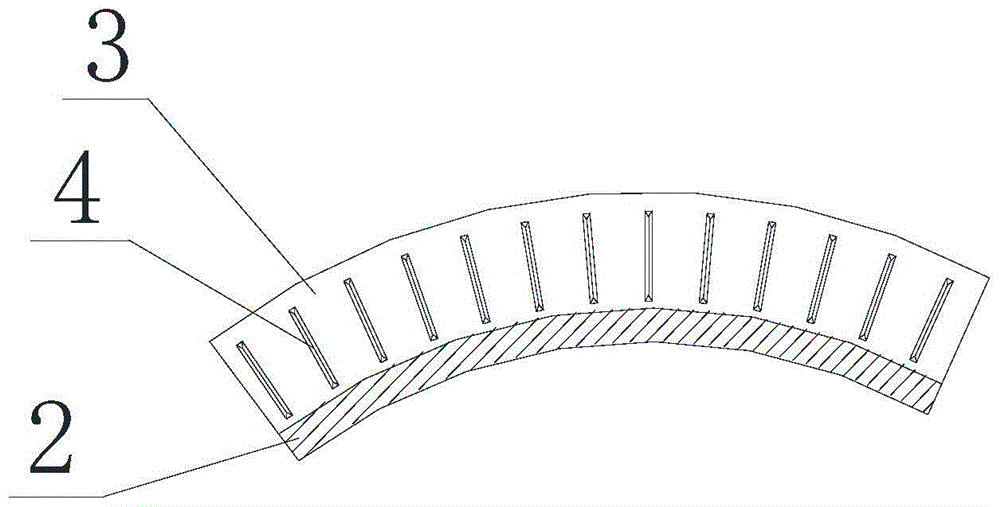

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] see Figure 1 to Figure 4 , a turbulent roller, including a roller core 1, the roller core 1 is a hollow roller core or a solid roller core, a number of annular friction plates 3 are detachably sleeved outside the roller core 1, and the annular friction plates 3 are evenly sleeved Set outside the roller core 1, the distance between each adjacent two annular friction plates 3 is 10-30 mm, the thickness of each annular friction plate 3 is 1-3 mm, and the distance between each adjacent two annular friction plates 3 is 10-30 mm. A spacer sleeve 2 is detachably installed, the roller core 1, the annular friction plate 3 and the spacer sleeve 2 are coaxially arranged, and a number of protruding strips 4 are evenly distributed on both surfaces of the annular friction plate 3. The protruding strips 4 The cross-sectional shape of the friction plate is a triangle, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com