Standing seam roof board-wind resisting fixed seat combination

A technology of standing seam and roof panels, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as limited stability of fixing seats, weak lateral rigidity, and damage to roof panels, and reduce Direct economic loss, simple and convenient construction, and the effect of improving wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with accompanying drawing:

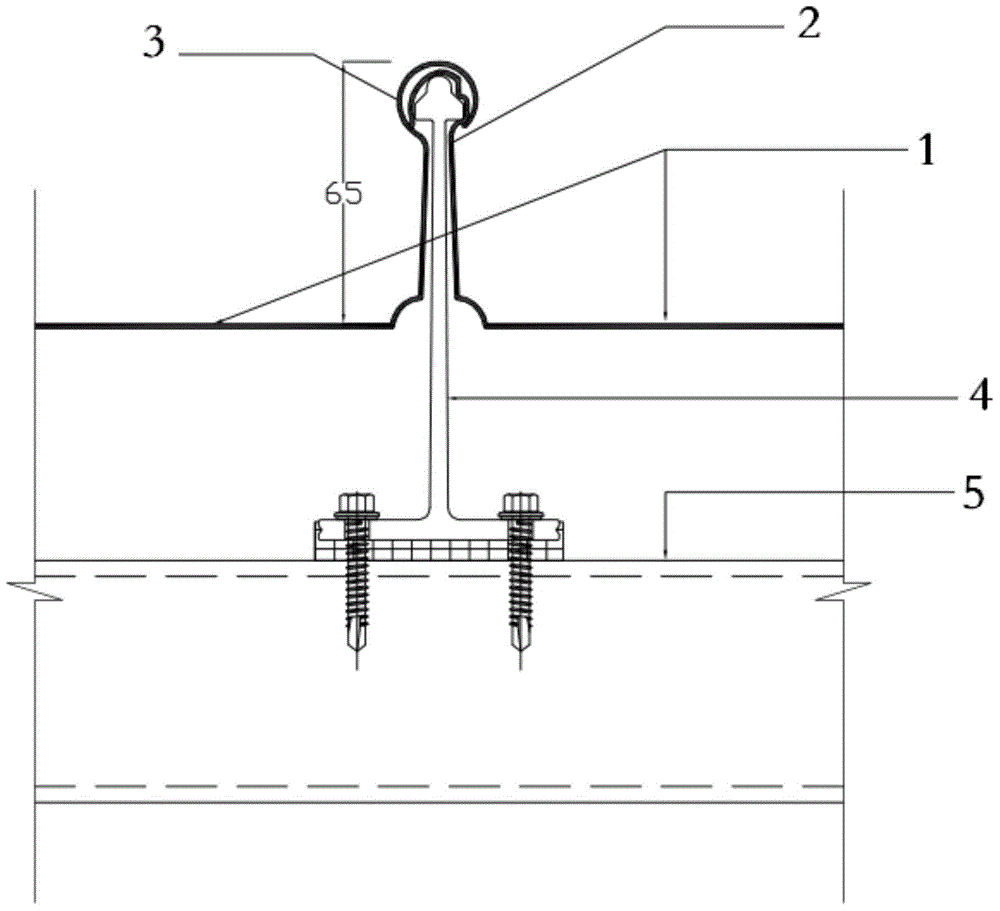

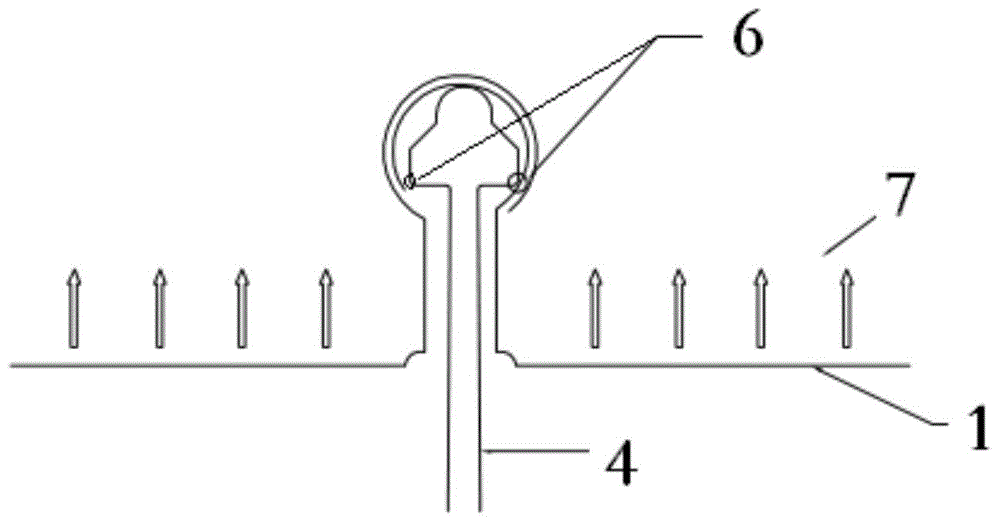

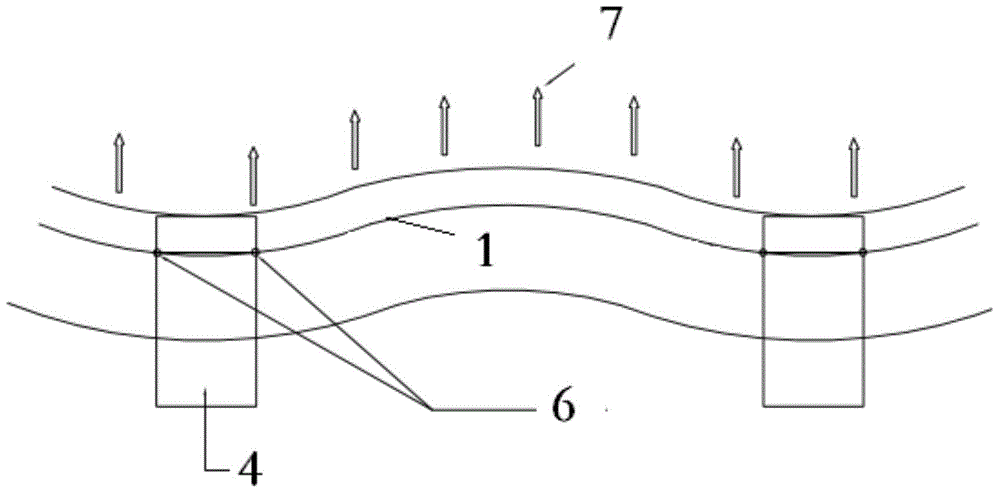

[0046] The present invention provides a combination of wind-resistant fixing seats for standing seam roof panels, including: roof panels 10, fixing seats 4 and fixing sleeves 11;

[0047]The roof panel 10 includes a roof panel body 1, a left vertical rib 2 and a right vertical rib 3 respectively extending from the left and right sides of the roof panel body 1; The end has a right hook-shaped crimp; the diameter of the right hook-shaped crimp is smaller than the diameter of the left hook-shaped crimp;

[0048] Such as Figure 5 As shown, it is a schematic diagram of the disassembled state of the fixed seat and the fixed sleeve; Figure 6 Shown is a schematic diagram of the combined state of the fixed seat and the fixed sleeve; from Figure 5 and Figure 6 It can be seen that the fixed seat 4 includes a fixed seat body 4-1 and a torx head 4-2 fixed on the top of the fixed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com