A casing material for super-deep hole grouting in underground excavation tunnels

A casing material and ultra-deep hole technology, which is applied in the engineering field, can solve the problems of slurry entering and jamming in the sleeve valve tube, and achieve the effects of small shrinkage, high brittleness, solidification time and strength growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

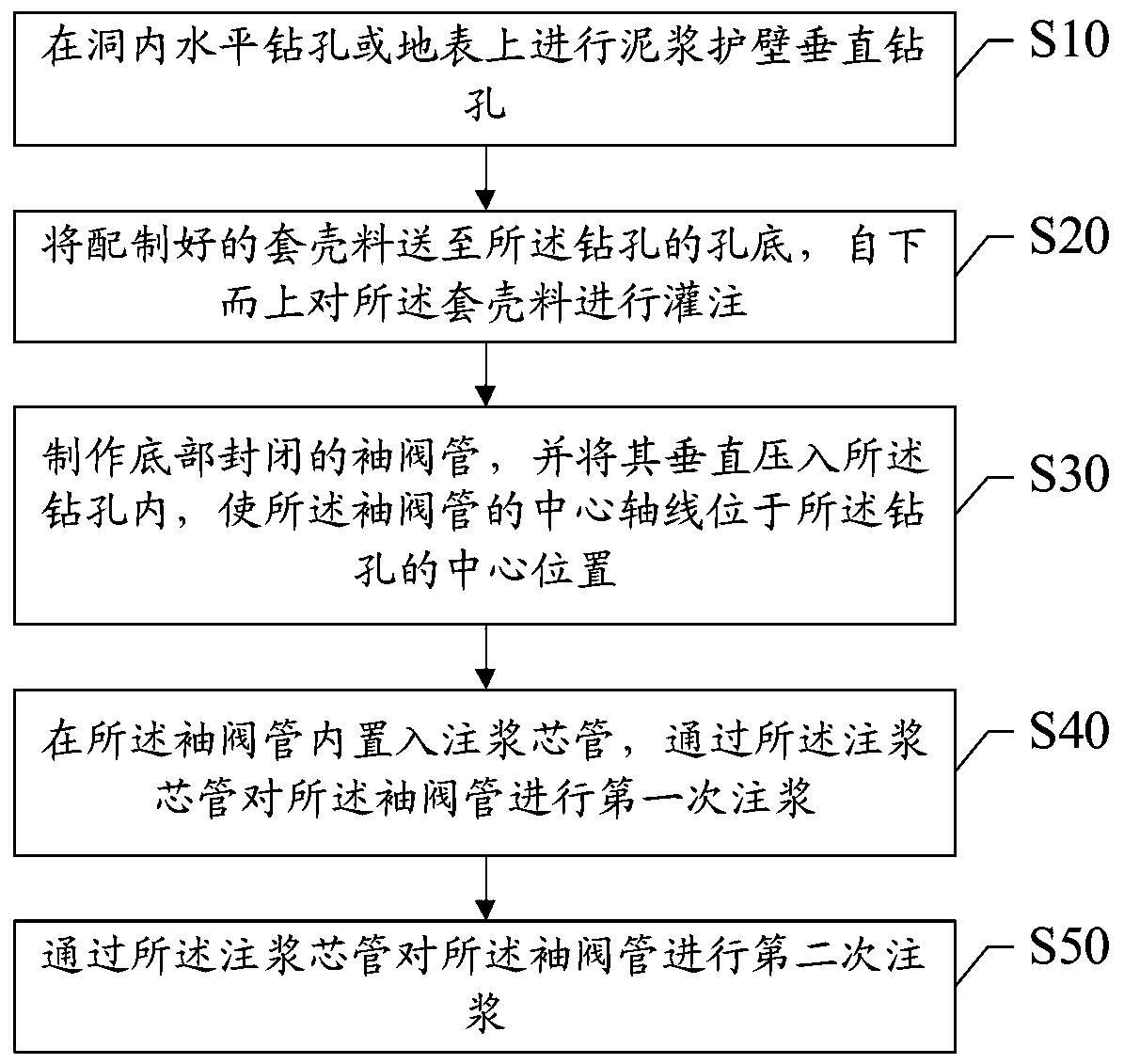

Method used

Image

Examples

other Embodiment approach

[0023] In other embodiments, the specific gravity of the slurry of casing material cement, bentonite, water and additives is 1.5, and the viscosity of the funnel is 24-26s, which can control the solidification time and strength growth rate of the casing material slurry within 2-5 days, Satisfy grouting conditions with optimum efficiency.

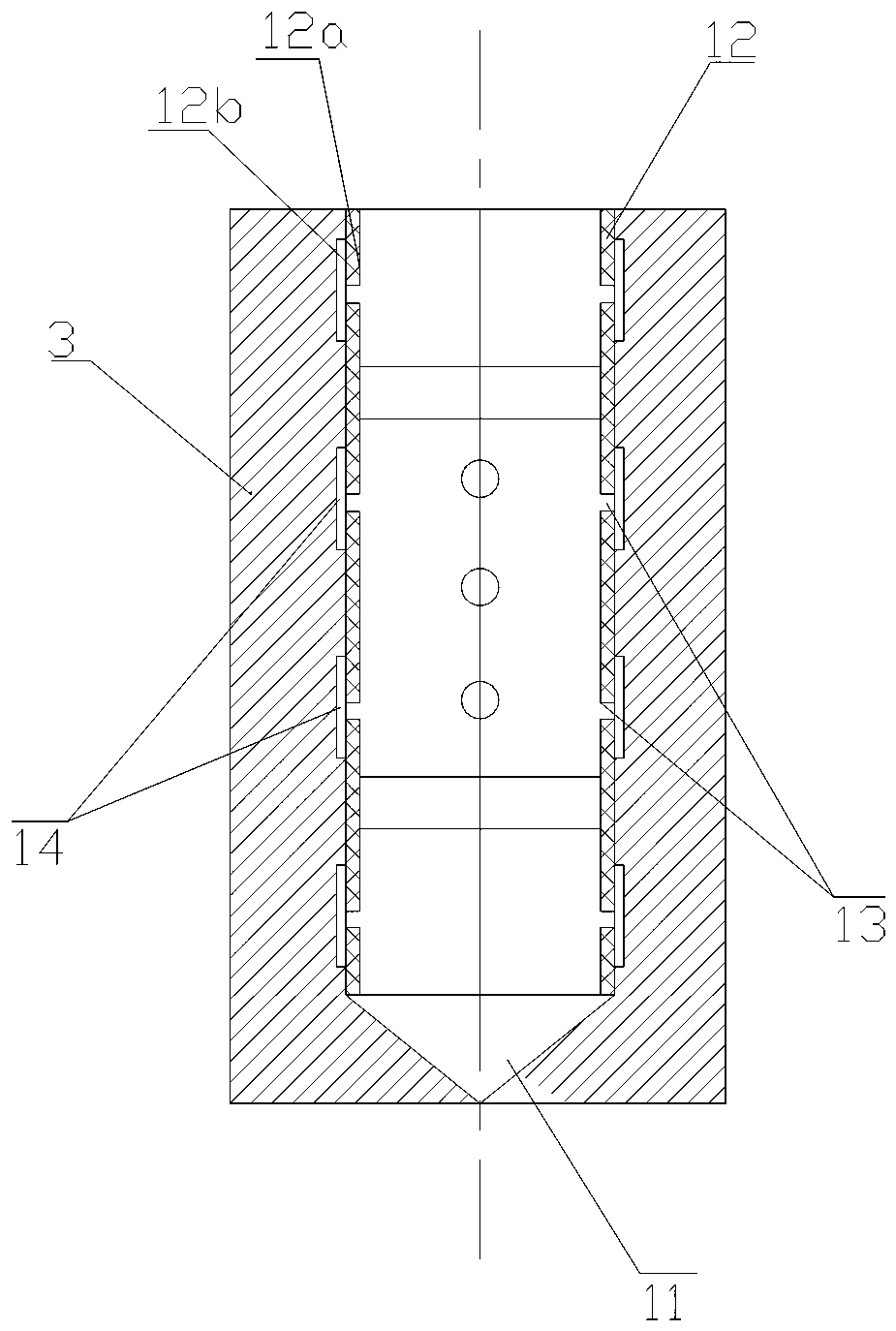

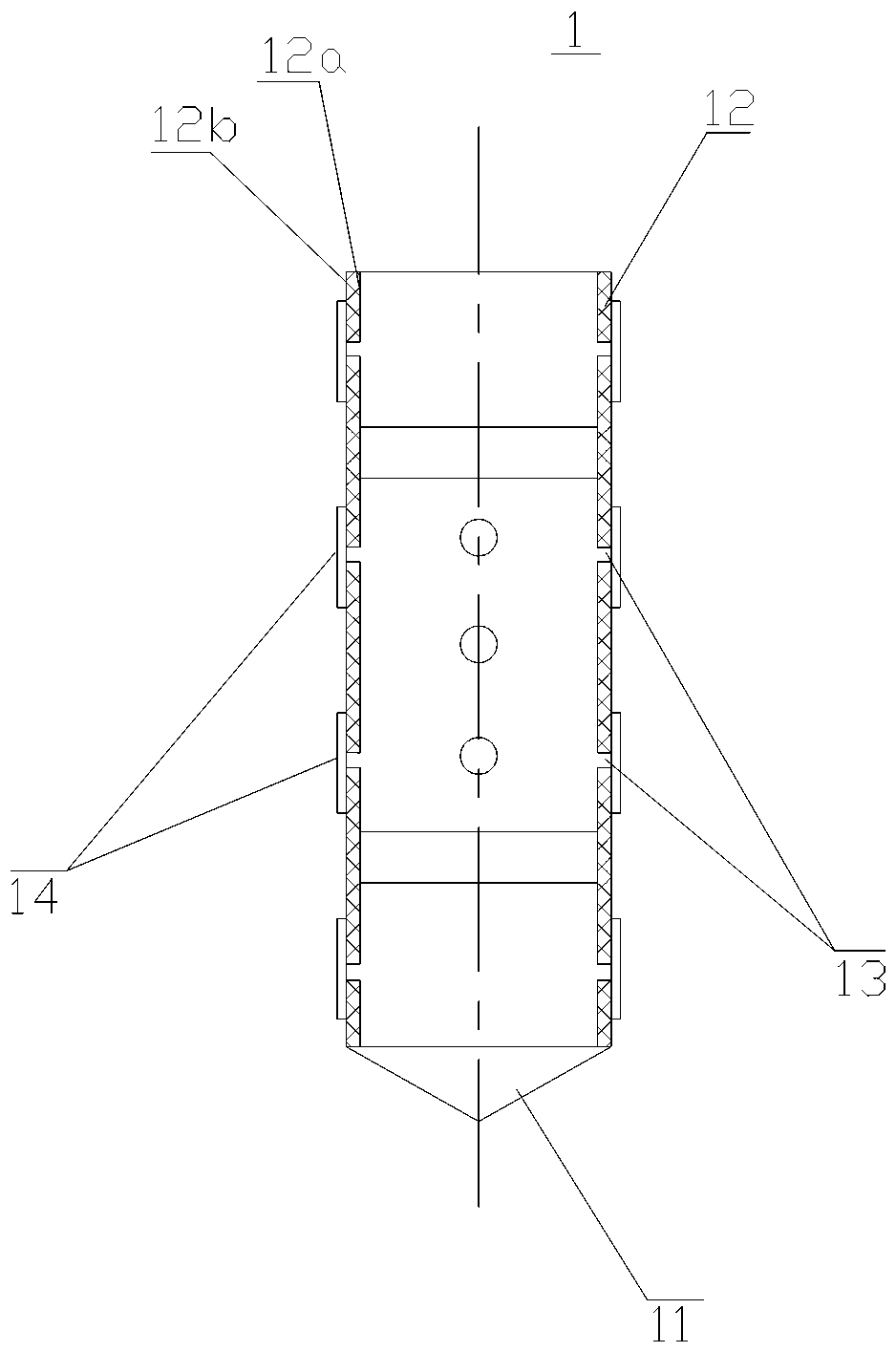

[0024] Preferably, the amount of casing=1.3×π*R*H. Among them: R = drilling radius * 2 - sleeve valve tube radius * 2, H = height of grouting section.

[0025] During specific implementation, after the casing material is poured into a hole, the drill pipe is lowered to the bottom of the hole, and the mixed casing material is injected into the grouting section in the hole through the drill pipe by a mud pump. Wherein: the slurry-stopping material is quick-setting cement slurry mixed with quick-setting agent, wherein: the quick-setting agent is water glass or calcium chloride, and the volume ratio of water and cement in the cement slurry is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com