Deepwater oil gas crossover pipe

A jumper, oil and gas technology, applied in the direction of pipes/pipe joints/fittings, pipe components, expansion compensation devices for pipelines, etc., can solve the problems of low natural vibration frequency, vortex-induced vibration fatigue damage, low structural damping, etc. Achieve the effect of weakening the fluid oscillation force, reducing the hydrodynamic diameter and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

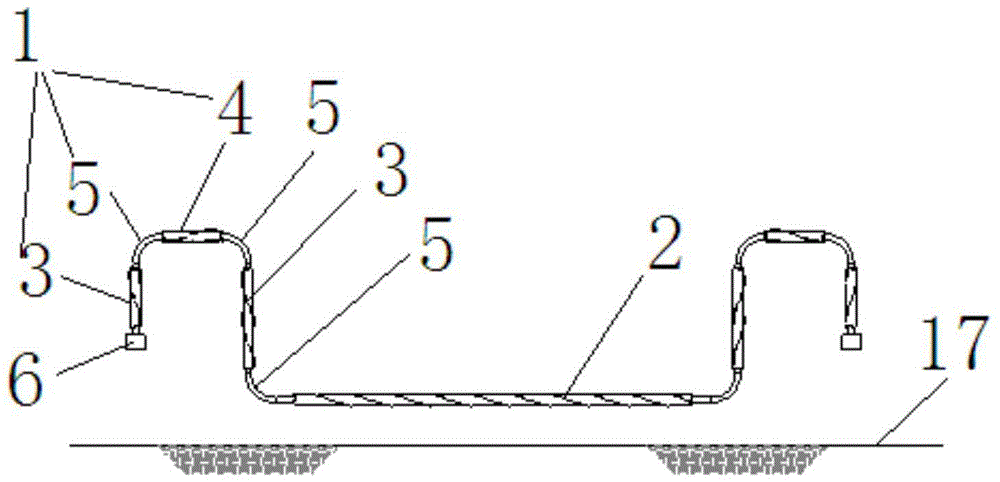

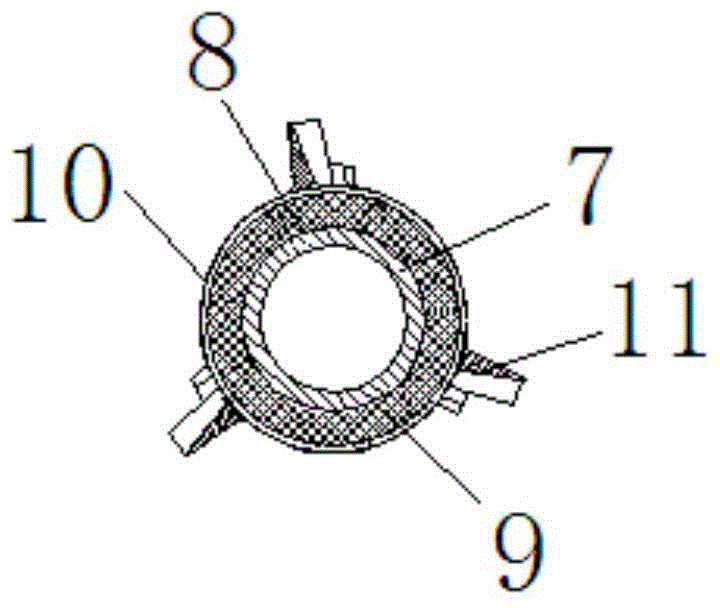

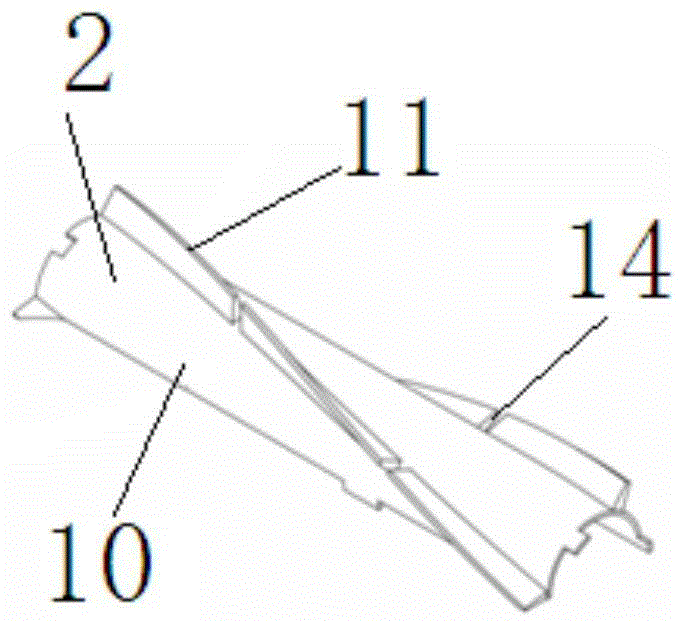

[0019] Such as figure 1 As shown, the present invention includes a pipe body 1 and a plurality of vortex-induced vibration suppression devices 2 .

[0020] The pipe body 1 includes a plurality of vertical straight pipe sections 3 , a plurality of horizontal straight pipe sections 4 and a plurality of bent pipe sections 5 connecting the vertical straight pipe sections 3 and the horizontal straight pipe sections 4 . Wherein, vertical straight pipe sections 3 and horizontal straight pipe sections 4 are alternately arranged, and each vertical straight pipe section 3 , horizontal straight pipe section 4 and bent pipe section 5 are all in the same plane. Two ends of the pipe body 1 are respectively provided with a hydraulic or mechanical connector 6 for connecting with facilities arranged underwater (such as a manifold, a Christmas tree or a docking system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com