Vertical resistance sensor

A resistance sensor and vertical installation technology, which is applied in the field of vertical resistance sensors, can solve the problems of unreasonable structure setting, poor safety, high assembly tolerance, etc., to improve work stability and use safety, reasonable structure, and reduce deformation loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

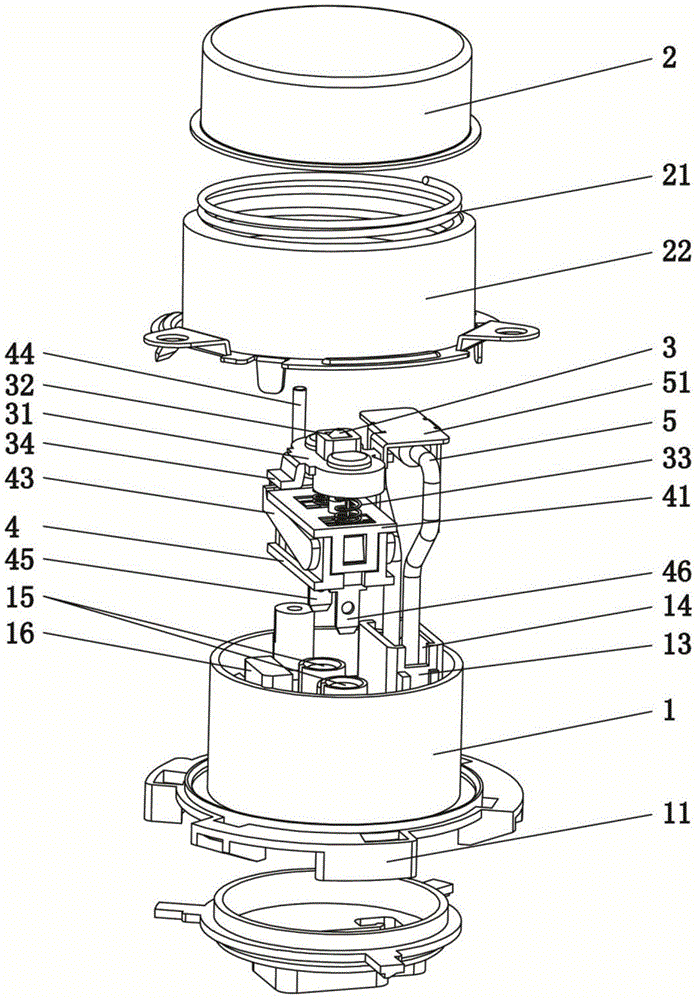

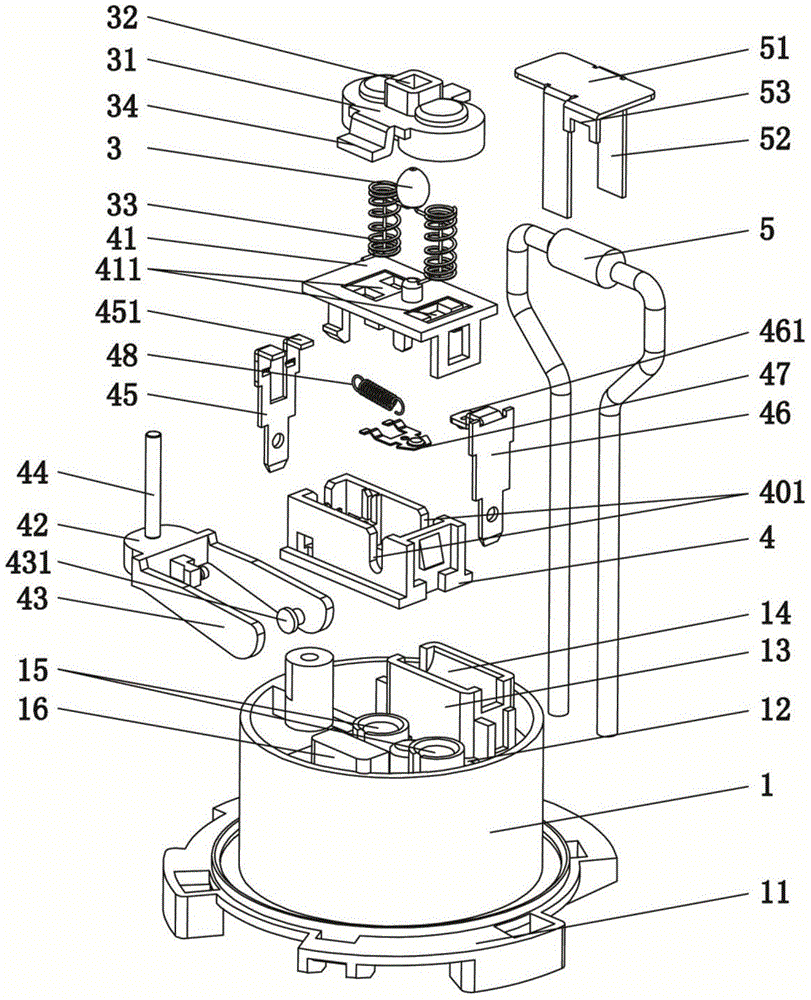

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] A vertical resistance sensor according to the present invention comprises a base 1, the upper end of the base 1 is provided with an upper cover 2 which moves up and down relative to it, a fixed plate 12 is arranged horizontally and horizontally inside the base 1, and a fixed plate 12 is provided on the fixed plate 12. The limit mechanism 13 matched with the upper cover 2, the base 1 below the fixed plate 12 is provided with a micro switch, and the micro switch is set in linkage with the upper cover 2; A bracket 31 is provided with a thermistor 3 that cooperates with the upper cover 2 , and both ends of the bracket 31 and the fixing plate 12 are provided with return springs 33 .

[0031] Such as Figure 1-2 As shown, the above-mentioned components are the main structure of the present invention. The upper cover 2 in the initial state is at the highest position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com