A High Sensitivity Fiber Bragg Grating Strain Sensor

A technology of strain sensor and optical fiber grating, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of unsuitable microstructure, large sensor volume, low strain sensitivity, etc., and achieve simple structure, small volume and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

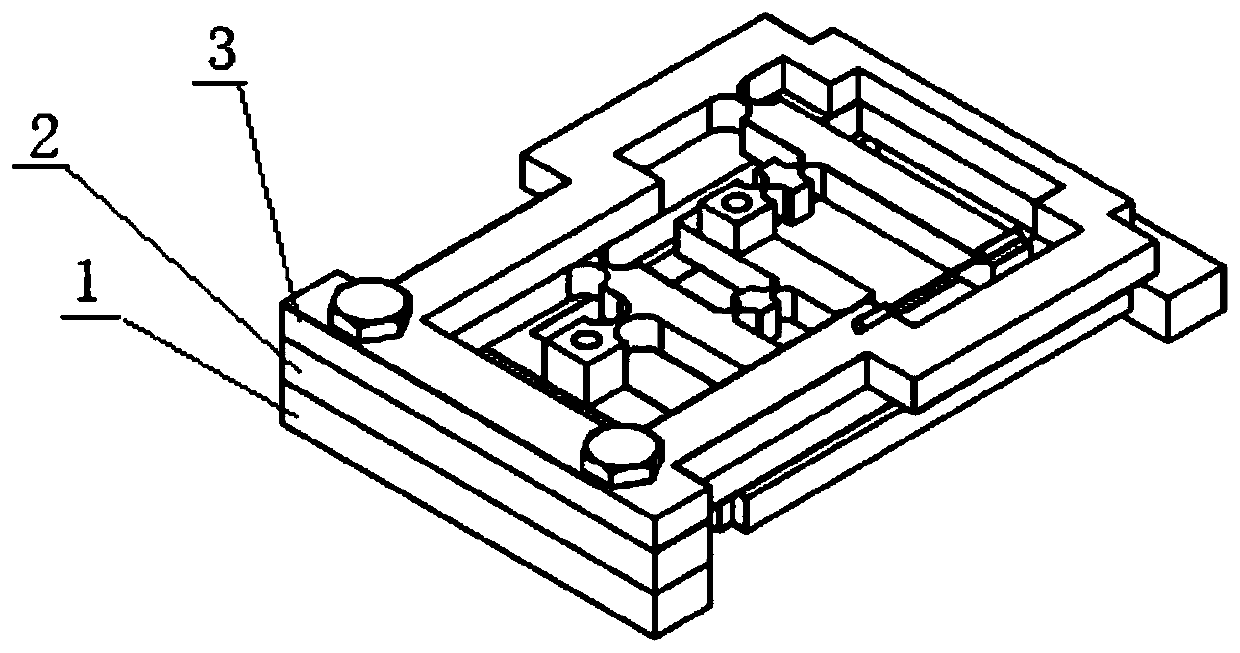

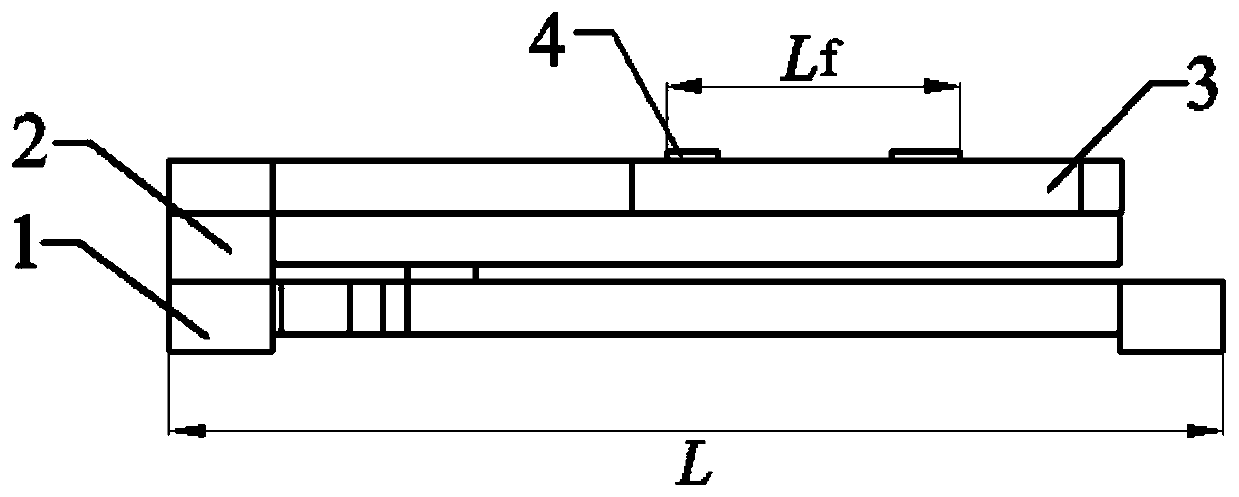

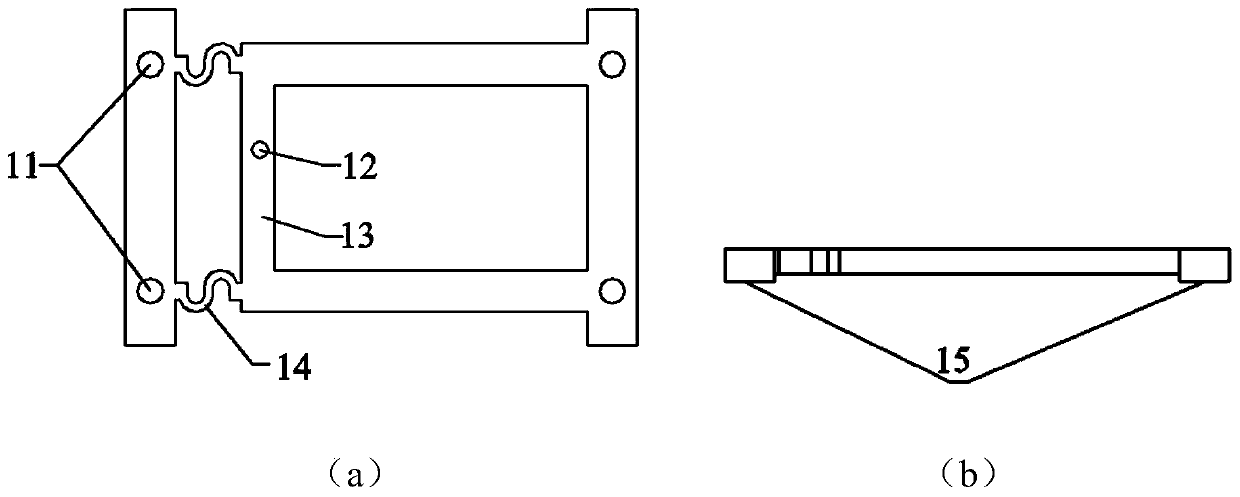

[0029] see Figure 1-5 , a high-sensitivity optical fiber grating strain sensor disclosed by the present invention comprises a detachably connected bottom metal sheet 1, a middle metal sheet 2 and a top metal sheet 3; a strain measurement grating 4 is installed on the top metal sheet 3, and the bottom metal sheet 1 is fixed on the object to be measured; there are lever mechanisms in the top and middle metal sheets, and the deformation of the object to be measured can be transmitted and amplified to the strain measurement grating 4 through the cascaded lever mechanism between layers.

[0030] see image 3 , Figure 4 with Figure 5 One end of the three-layer metal sheet is provided with a metal sheet connection hole that can be matched with a bolt, the bottom metal sheet 1 is a bottom metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com