Fuzzy clustering steel plate surface defect detection method based on pre classification

A technology of fuzzy clustering and defect detection, applied in image analysis, character and pattern recognition, instruments, etc., can solve the problem of low classification accuracy, eliminate low contribution rate, optimize feature vector, reduce missed judgment and misjudgment rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings.

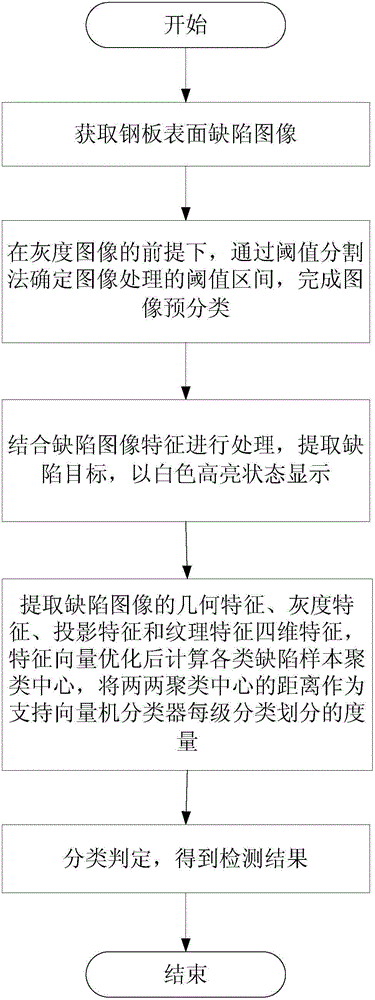

[0043] see figure 1 , a method for detecting steel plate surface defects based on pre-classification fuzzy clustering, including the following steps:

[0044] S1: Take the real-time images taken by the steel plate production line as the source image of the steel plate surface defect detection, and directly extract the steel plate defect image under the conditions of the existing steel plate surface defect detection device;

[0045] S2: Process the defect image acquired in step S1, and determine the threshold interval of the image processing through the threshold segmentation method on the premise of the grayscale image, and complete the image pre-classification; specifically include the following steps:

[0046] S21: Gray-value the defect image acquired in step S1;

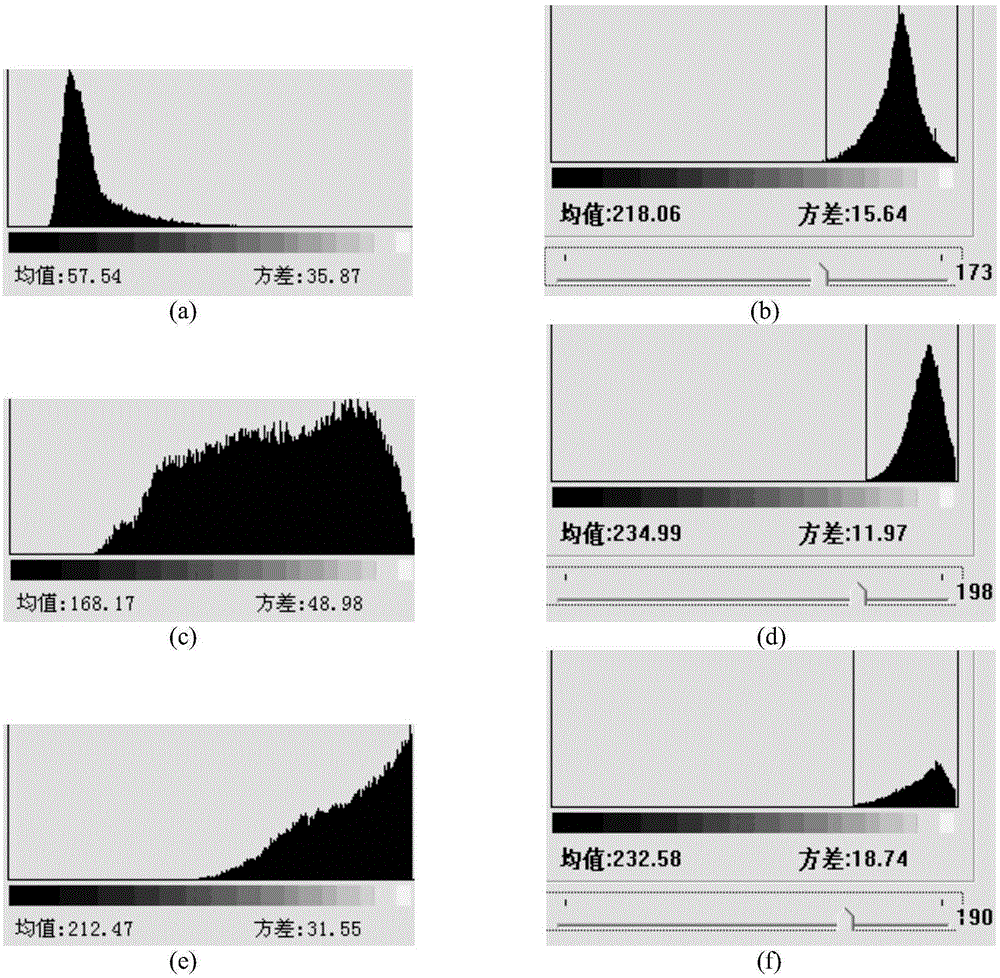

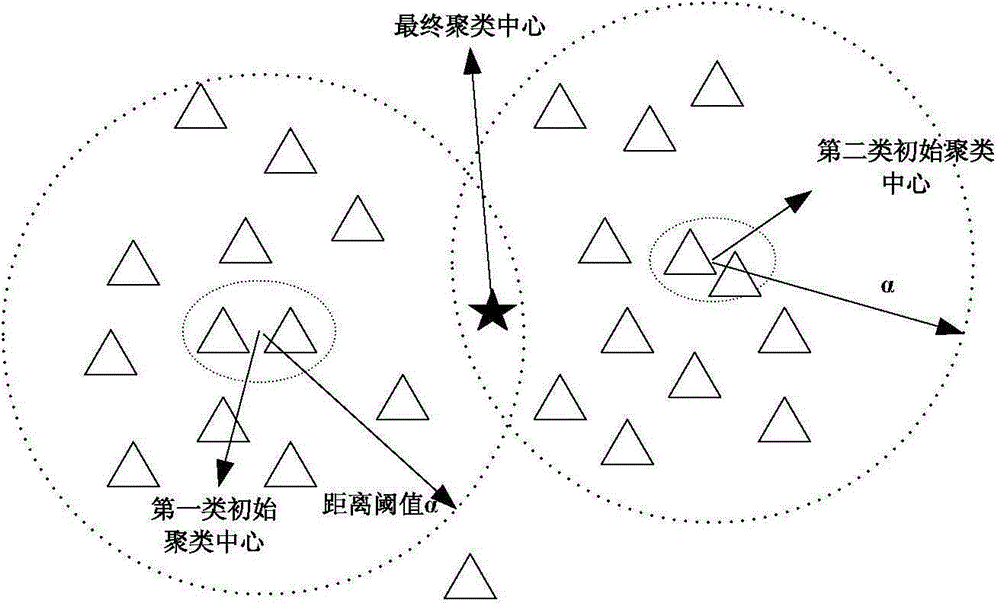

[0047] S22: Draw a histogram of the gray-scaled defect image, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com