Electronic circuit component mounting head

An electronic circuit and mounting head technology, applied to electrical components, electrical components, etc., can solve the problem that it is difficult to detect the contact between the suction nozzle and the object, it is difficult to fully reduce the contact impact, and it is difficult to sensitively control the second lift. Problems with drives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]Hereinafter, embodiments of the claimable invention will be described with reference to the drawings. In addition, as an invention that can be claimed, in addition to the following embodiments, it is also possible to implement various changes based on the knowledge of those skilled in the art, as represented by the aspects described in the above-mentioned [Aspects of the Invention] implement.

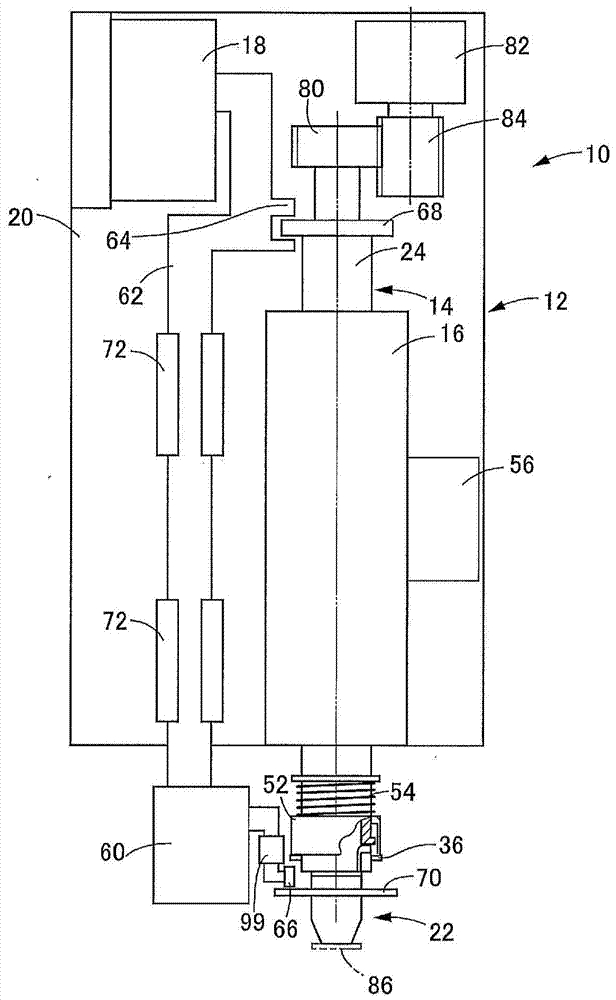

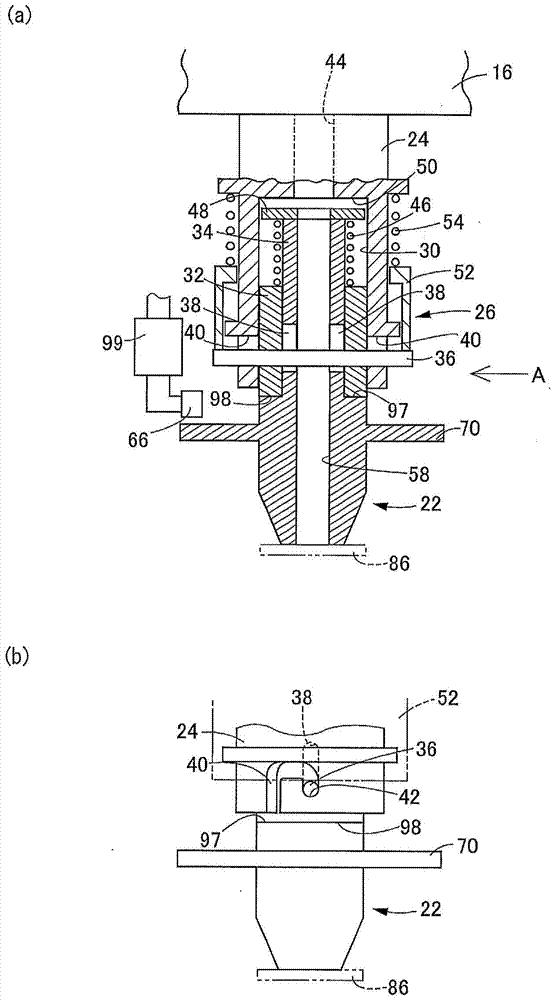

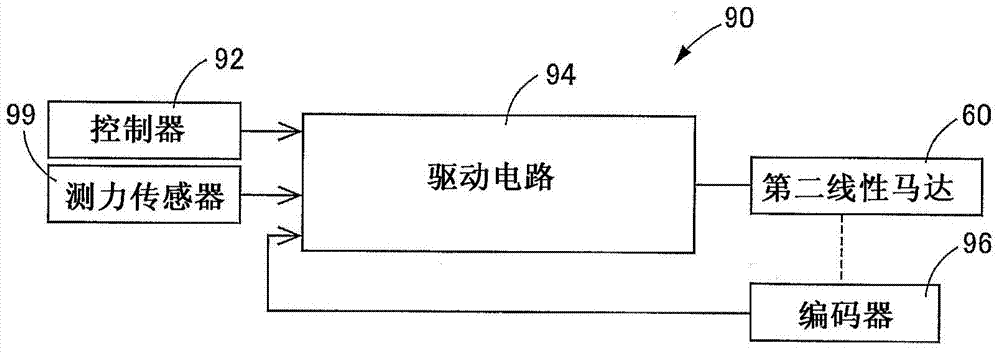

[0056] exist figure 1 An example of the basic structure of the mounting head 10 is shown in . The mounting head 10 has a mounting head body 12, the mounting head body 12 has a first portion 16 and a second portion 20, the first portion 16 allows the lifting of the rotating lifting shaft 14 in a direction parallel to its axis and around its axis. The rotating elevating shaft 14 is held in a rotating state, and the second part 20 holds the first linear motor 18 fixedly. In this embodiment, the first part 16 and the second part 20 are fixed to each other. A suction nozzle 22 serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com