Twisting structure used for ultrasound knife connection and ultrasound knife comprising twisting structure

A technology of ultrasonic knife and knife bar, which is applied in the field of medical equipment, can solve the problems of wrench pollution, easy loss, inconvenience of ultrasonic knife, etc., and achieve the effect of ensuring normal connection, not easy to make mistakes, and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

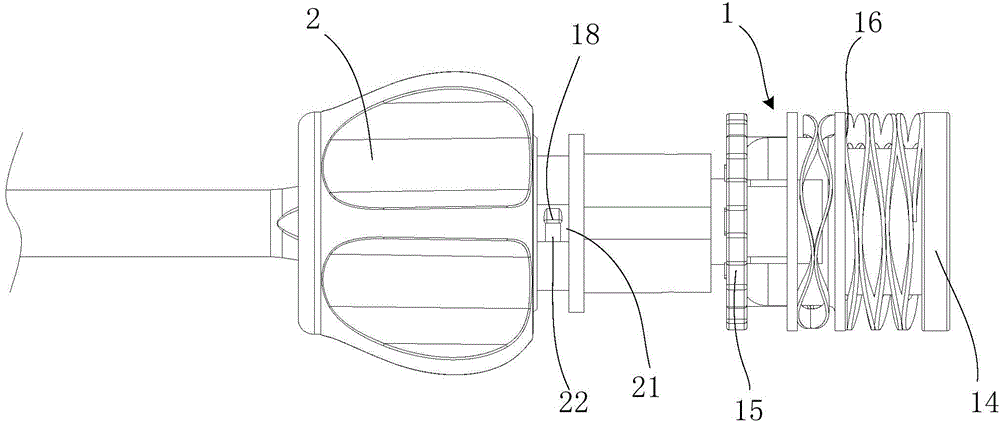

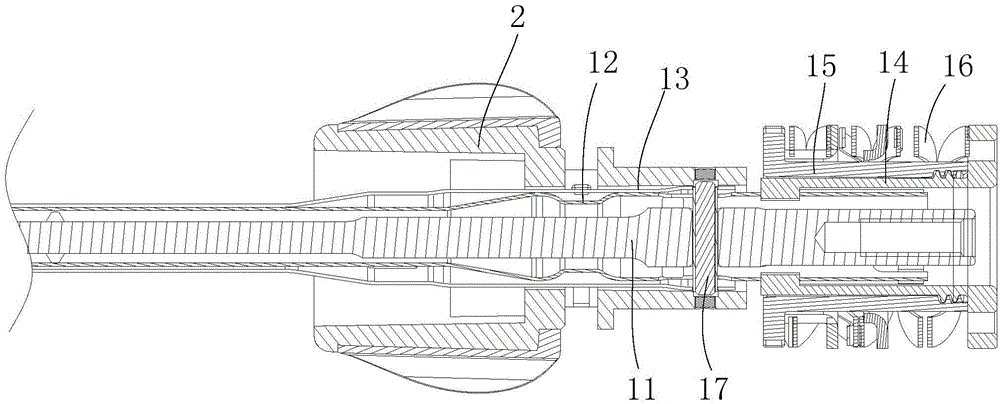

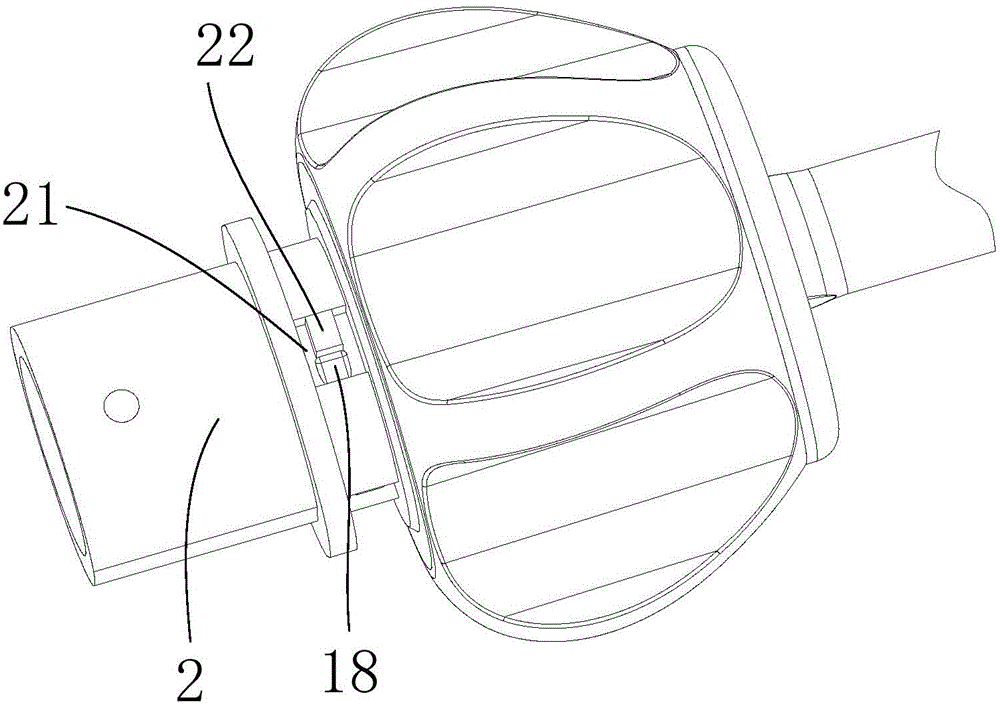

[0040] like Figure 1 to Figure 4 As shown, the present invention provides a twisting structure for ultrasonic scalpel connection, including a knife bar assembly 1 and a knob body 2 sleeved outside the knife bar assembly 1. In this example, the knife bar assembly 1 includes an inner sleeve 12 and The connecting head 14 connected to the rear of the inner sleeve 12, the inner sleeve 12 is set outside the ultrasonic action rod 11, the inner sleeve 12 is covered with an outer sleeve 13, and the inner sleeve 12 and the ultrasonic action rod 11 are respectively connected with a shear head, The same pin 17 vertically passes through the outer casing 13 , the inner casing 12 and the ultrasonic action rod 11 ; The elastic supporting mechanism 16 is looped over the limit sleeve 15, and the two ends respectively abut against the limit sleeve 15 and the connecting head 14.

[0041] At least two stoppers are arranged on the outer wall of the outer sleeve 13 in the circumferential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com