A system for suppressing crystallizer liquid level fluctuations at high lifting speeds

A technology for inhibiting crystallization and liquid level fluctuation, applied in the field of mold process optimization, can solve problems such as poor effect, uneven distribution of molten steel volume, uneven impact of mold slag, etc. Effect of Surface Wave Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

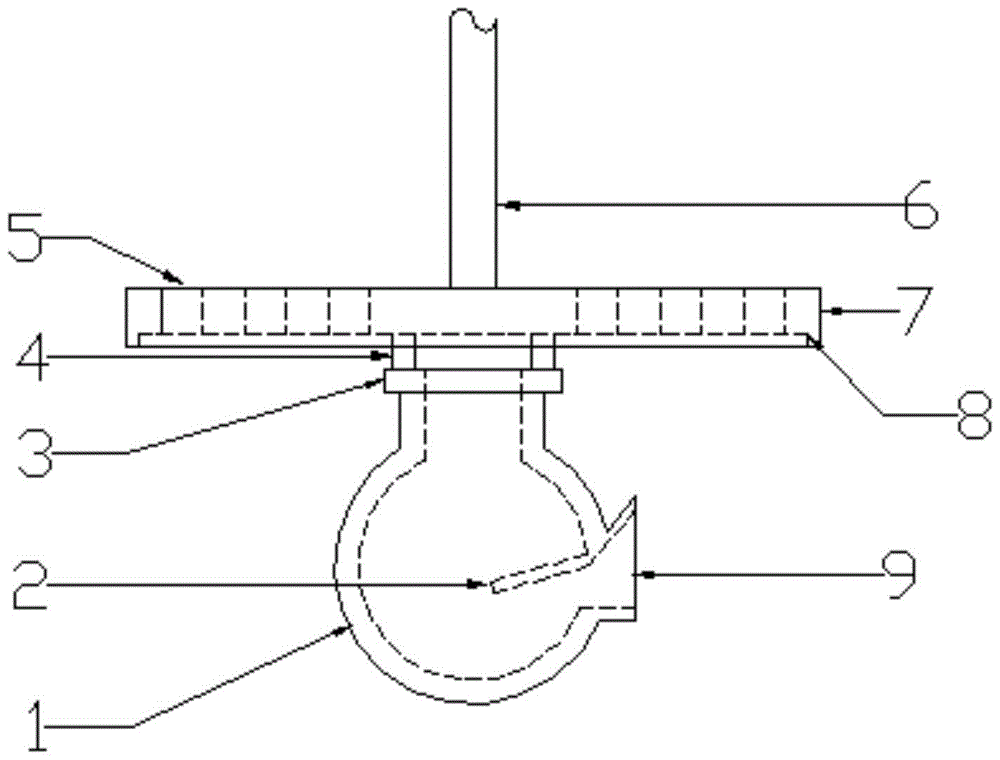

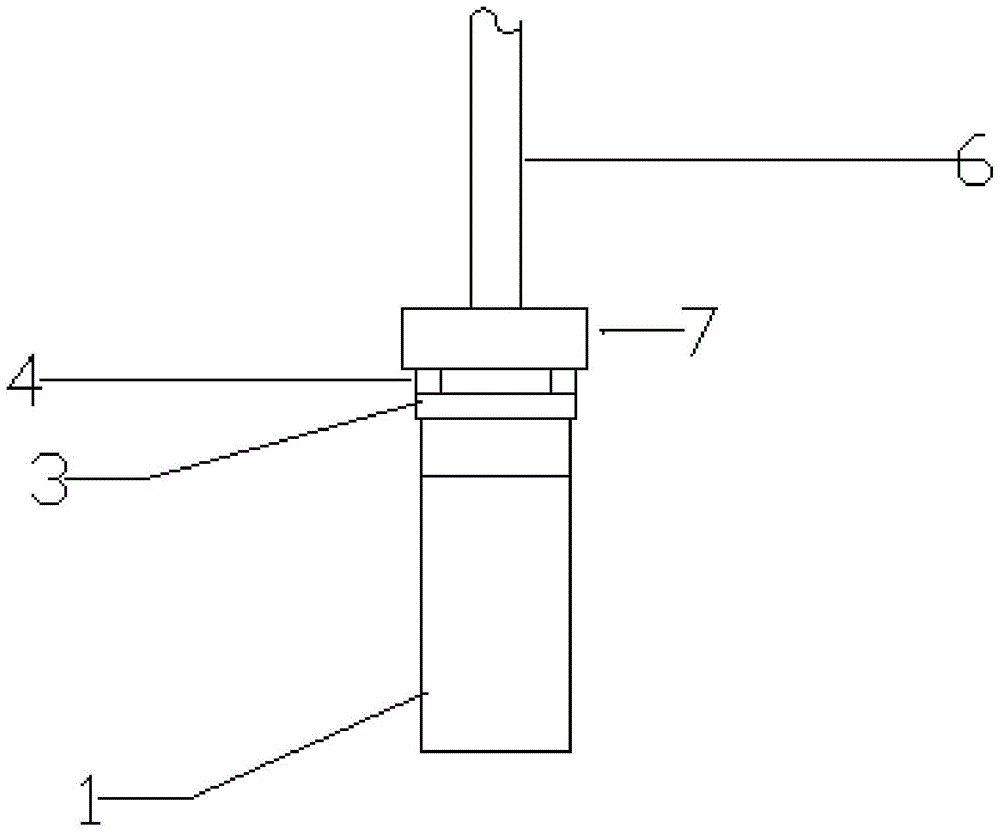

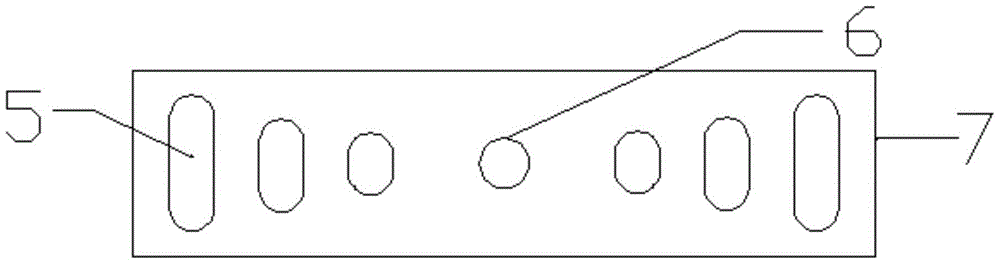

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a system for suppressing crystallizer liquid level fluctuations at high lifting speeds in this embodiment includes a main unit and a lifting unit. Among them: the main unit includes a converging mechanism, a diverting mechanism and a connecting mechanism. The converging mechanism can first gather the jet 13 ejected from the side hole of the submerged nozzle 10 to reduce its momentum, and then the diverging mechanism can evenly release the liquid flow with reduced momentum. , crystallizer liquid level fluctuations are well suppressed. The connection mechanism is respectively used to connect the flow gathering mechanism and the flow diversion mechanism, and the flow diversion mechanism and the lifting unit.

[0038] The converging mechanism includes a concentrator 1, a baffle plate 2, an outlet 3 and a converging port 9. The concentrator 1 is a cylinder with a cylindrical cavity inside the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com