Plate blank submersed nozzle capable of inhibiting liquid level fluctuation

A liquid suppression, immersion technology, applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc., can solve the complex internal structure of the molten steel impact kinetic energy device, reduce the efficiency and production cycle of continuous casting production lines, and reduce the hole area. Completely utilized and other issues to achieve the effects of suppressing liquid level fluctuations, reducing turbulent kinetic energy, and reducing impact kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

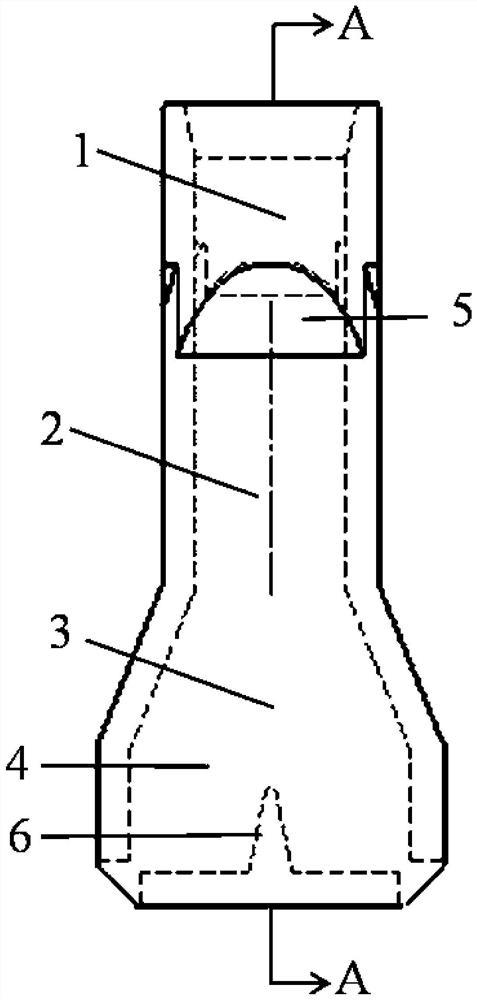

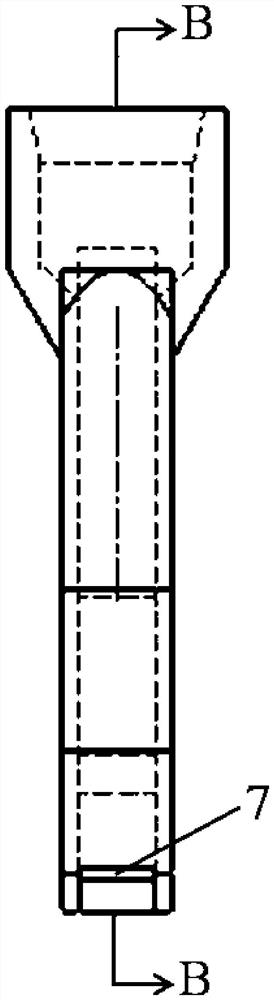

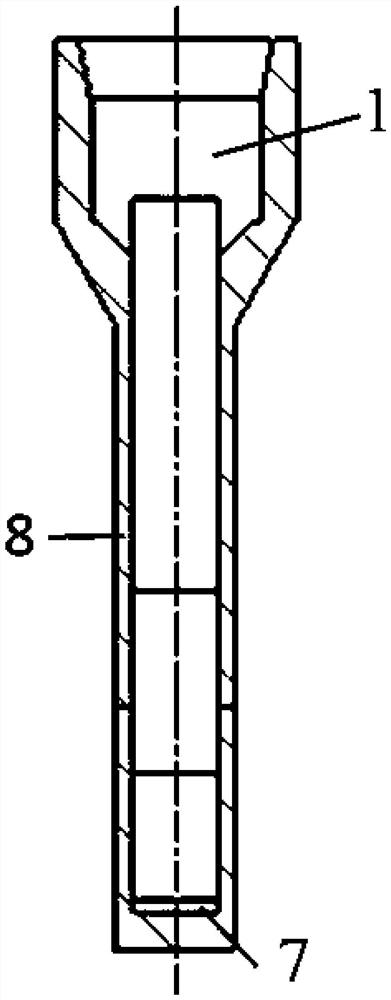

[0025] The slab submerged nozzle that suppresses fluctuations in the liquid level includes a nozzle body and an outlet. The nozzle body is a cylinder surrounded by side plates 8. The nozzle body includes a cylindrical cavity 1 and an upper rectangular body from top to bottom. Cavity 2, isosceles trapezoidal cavity 3 and lower rectangular cavity 4; the top of the cylindrical cavity 1 is open, and the bottom of the inner wall of the cylindrical cavity 1 is connected with the top of the inner wall of the upper rectangular cavity 2 through the diversion slope 5; the diversion slope 5 is the surface that transitions from the bottom of the inner wall of the cylindrical cavity 1 to the top of the inner wall of the rectangular cavity 2, and the sides above the diversion slope 5 are the bottom edges of the top of the inner wall of the rectangular cavity 2, and are symmetrically a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com