Pull rod mechanism

A pull-rod mechanism and pull-rod technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of complex operation, high installation accuracy, and increase equipment production costs, and achieve the goal of reducing installation accuracy, improving production efficiency, and easy program control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

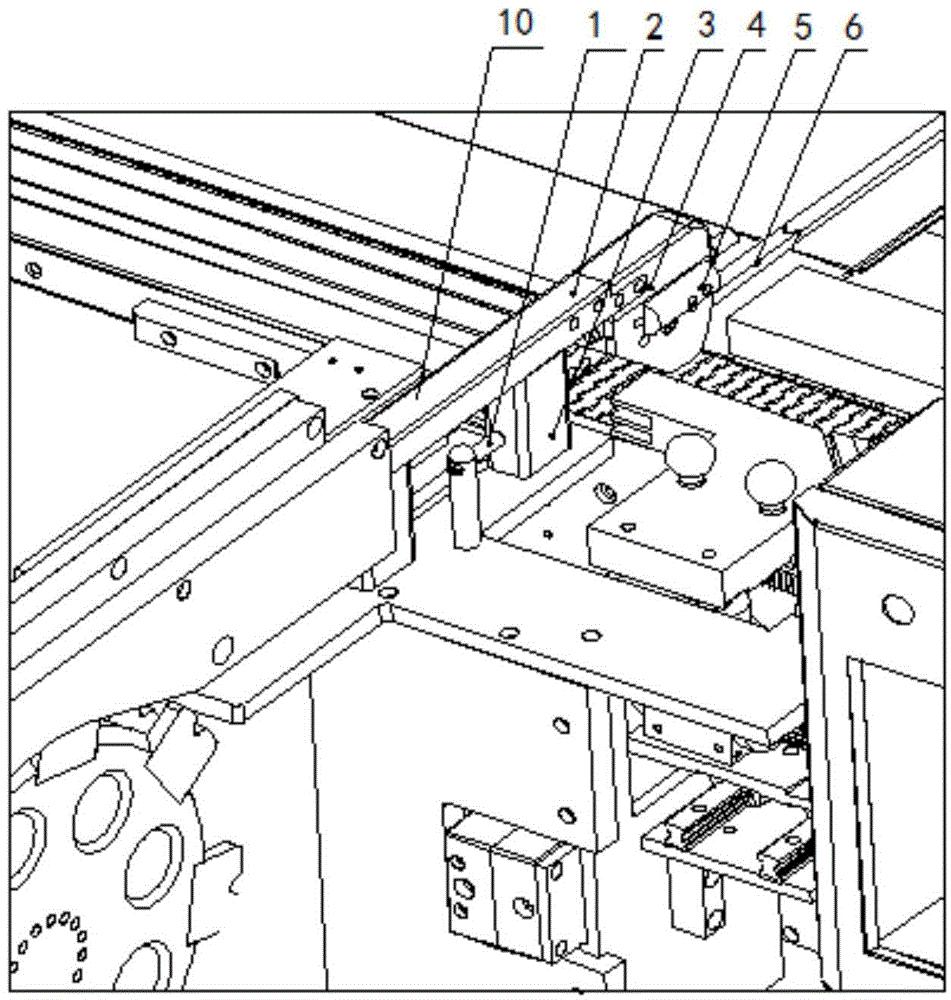

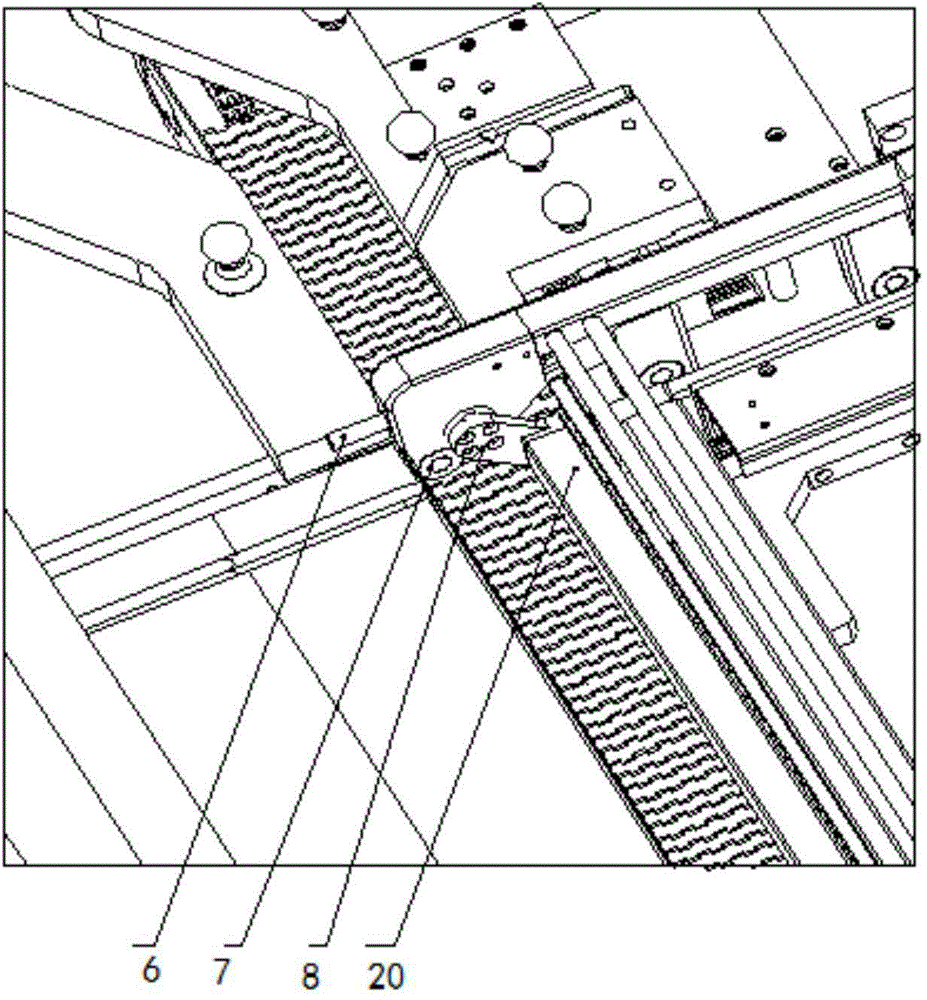

[0014] see Figure 1-2 , a pull rod mechanism provided by the present invention includes a vial pull rod 20 and two sets of identical overturn assemblies 10, the overturn assemblies 10 are respectively arranged at both ends of the vial pull rod 20, and the overturn assembly 10 controls the movement of the vial pull rod 20. The overturn assembly 10 includes a overturn body 4, a rotating shaft 8 and a down bumper 6. Each end of the vial pull rod 20 is connected to the overturn body 4 through the rotation shaft 8, and the down over bump 6 is connected with the rotating shaft 7. The pull bar mechanism also includes an upturn Lever 1 and upturning bumper 5, upturning bumper 5 is arranged on the turning body 4, and is connected with rotating shaft 8, and upturning bumper 1 is fixed on the moving path of upturning bumper 5, in practical applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com