Patents

Literature

34results about How to "Simple program control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

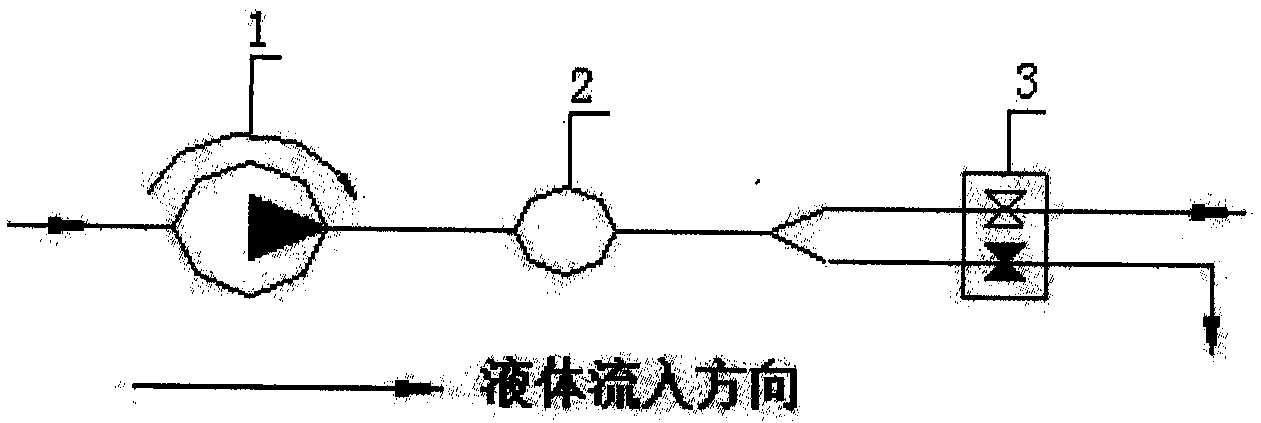

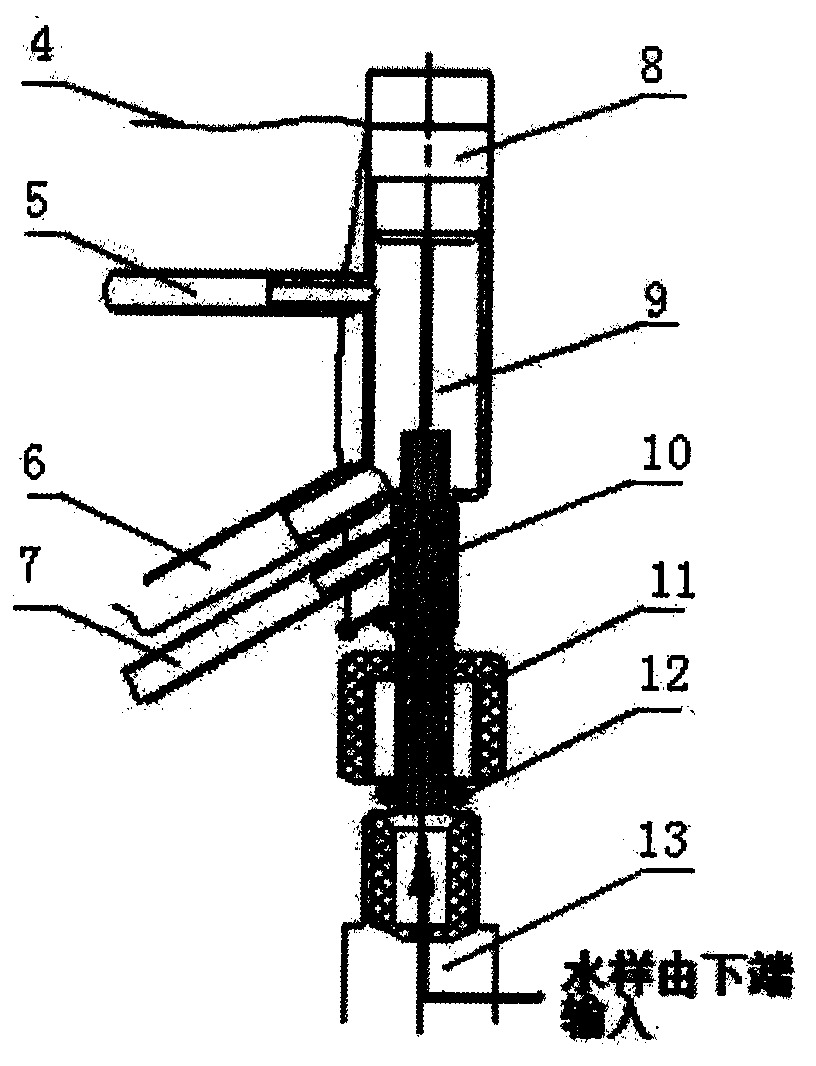

Accurate liquid extracting and metering device and method

ActiveCN101655423AEfficient screeningSimple program controlWithdrawing sample devicesCapacity measurement calibrationEngineeringLiquid extract

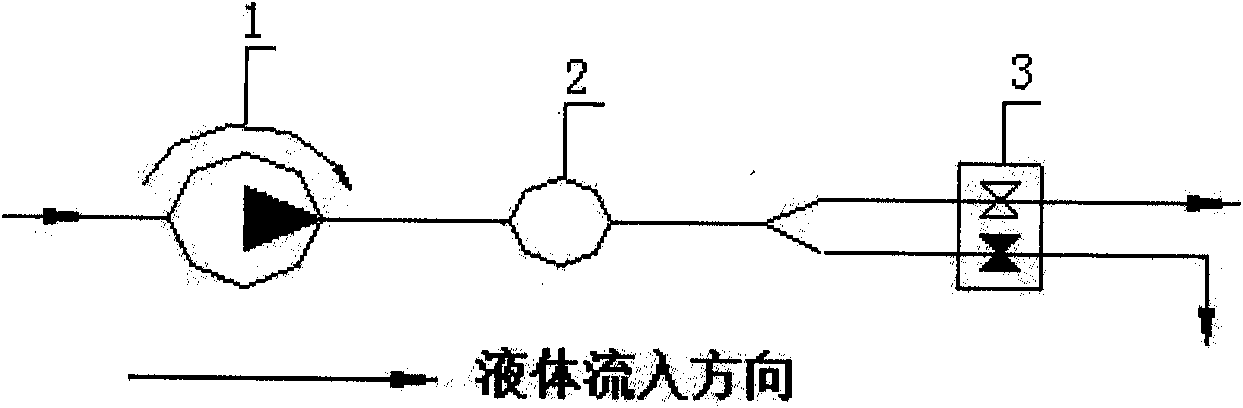

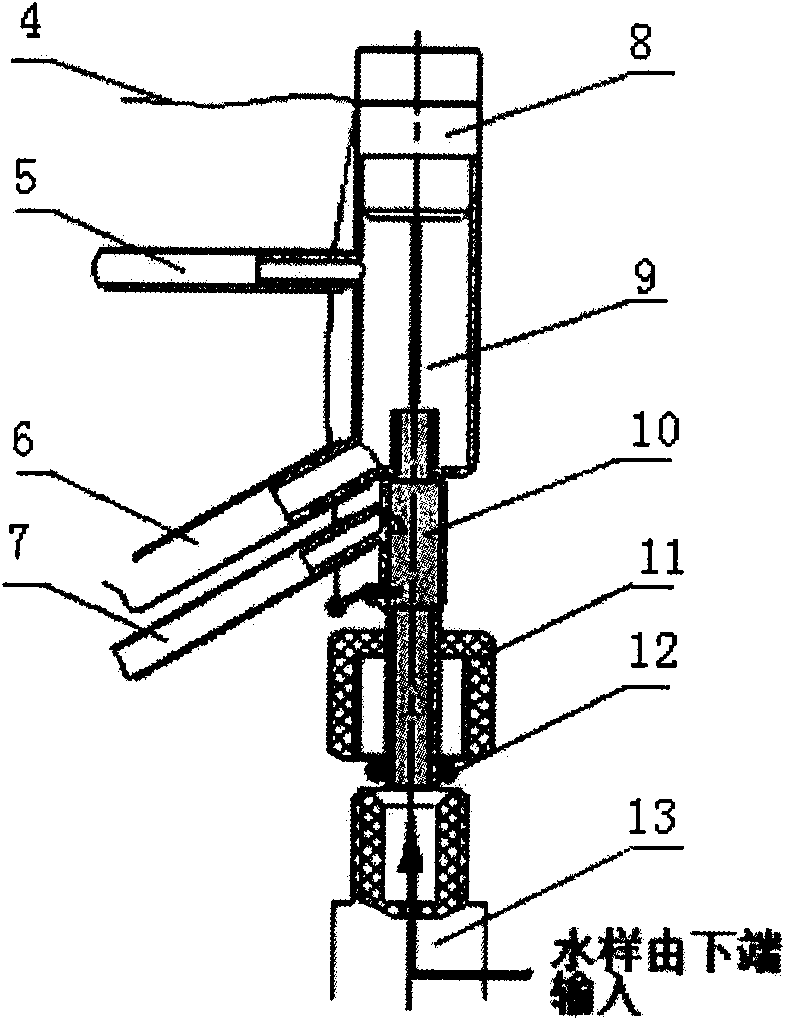

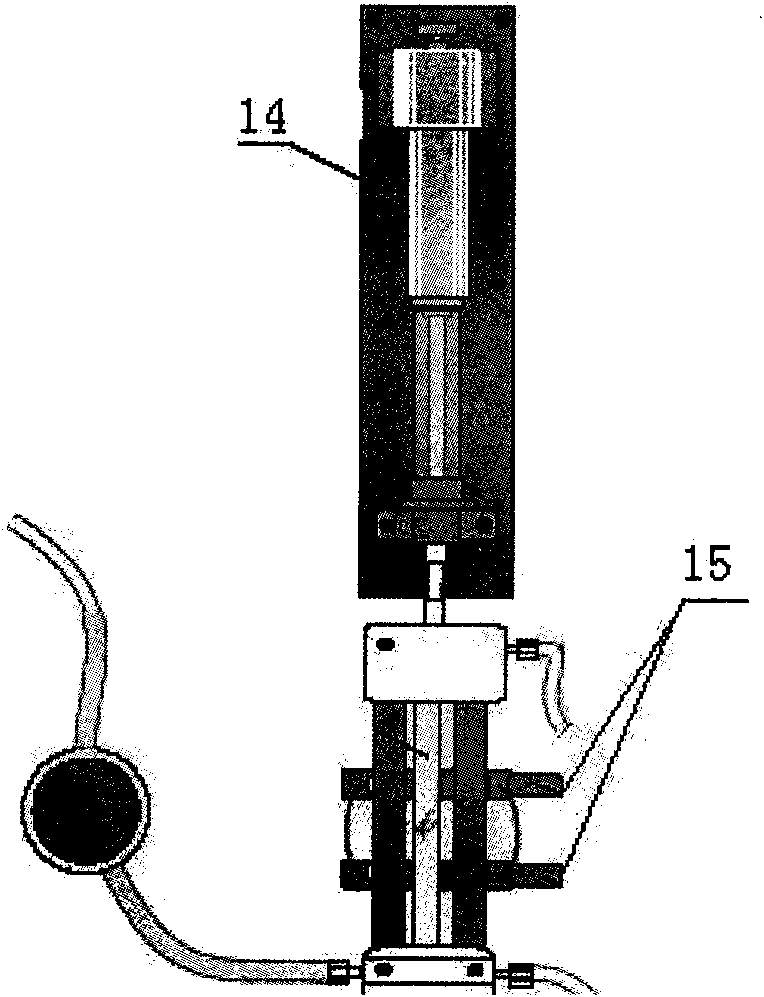

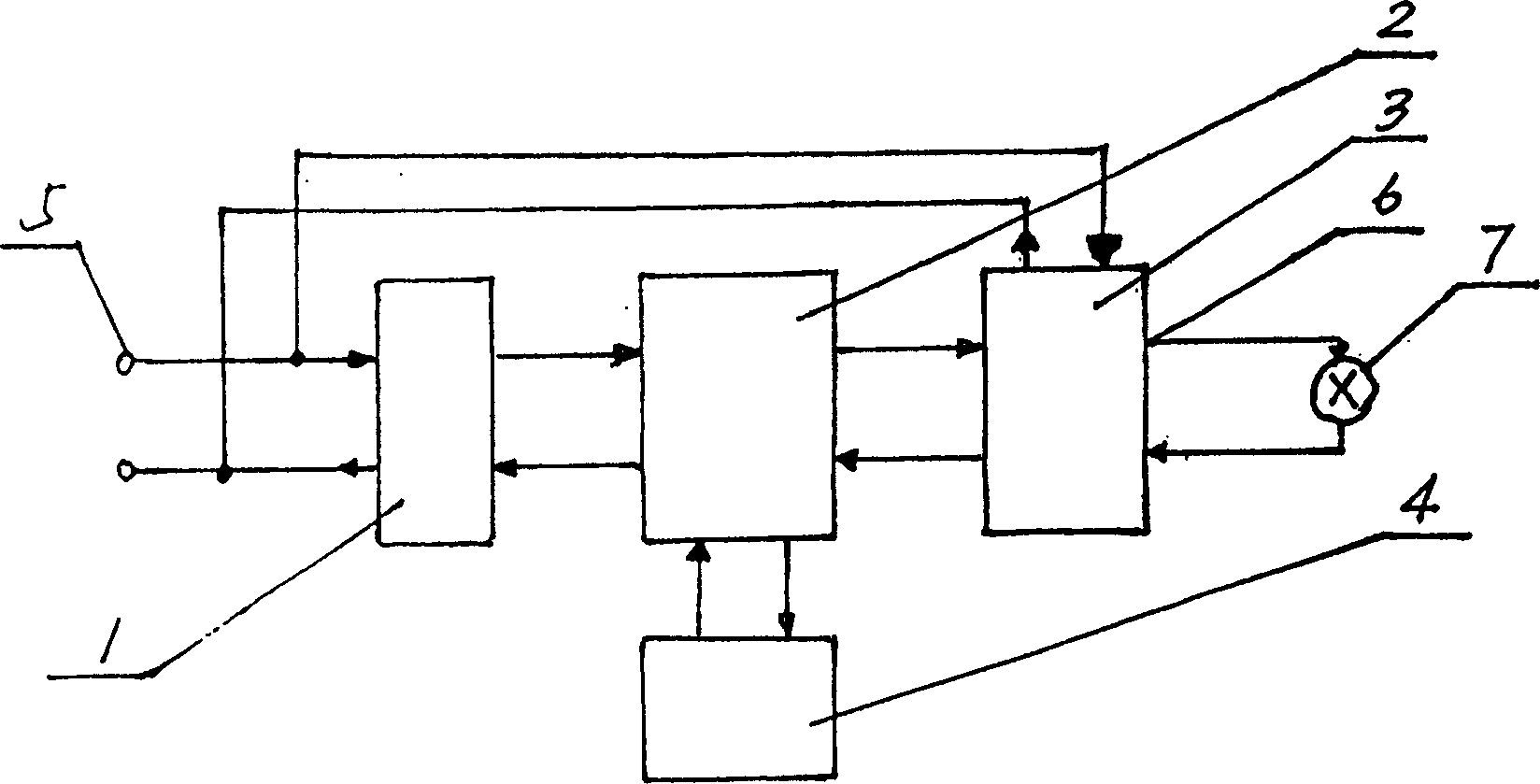

The invention discloses an accurate liquid extracting and metering device and a method. The device comprises a pump, a valve unit, an electromagnetic stop valve, a liquid storing unit, a testing module, a liquid detector A and a liquid detector B, wherein the valve unit is provided with a liquid inlet passage, a testing passage, a liquid discharging passage and a common passage connected with theliquid storing unit; the liquid inlet passage of the valve unit is connected with liquid; the testing passage is connected with the testing module; the liquid discharging passage is connected with a waste liquid collecting device; the common passage is connected with one end of the liquid detector A by the electromagnetic stop valve, and the other end of the liquid detector A is connected with oneend of the liquid storing unit; the other end of the liquid storing unit is connected with one end of the liquid detector B, and the other end of the liquid detector B is connected with the pump.

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

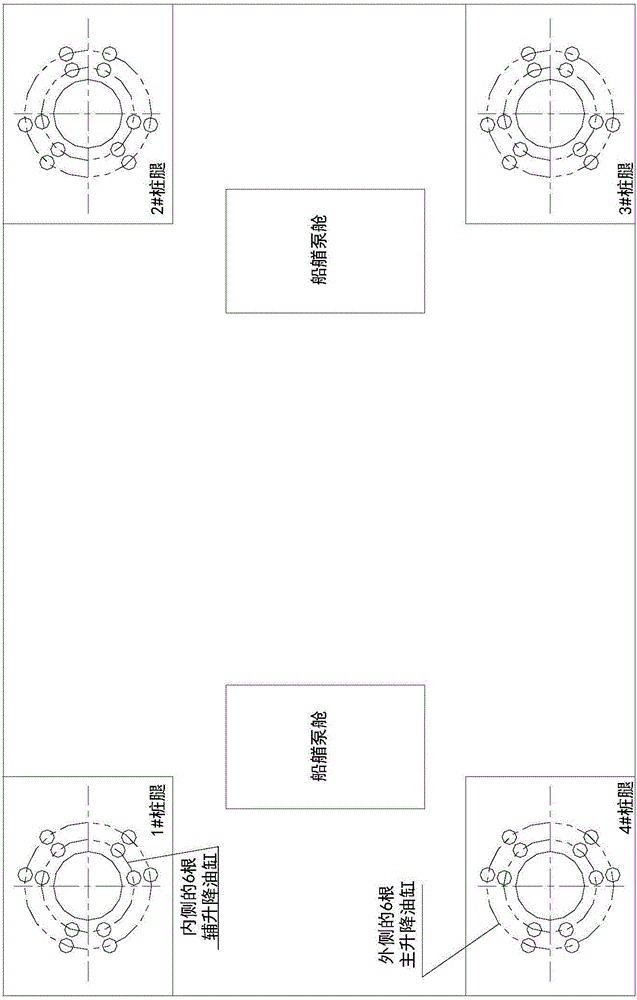

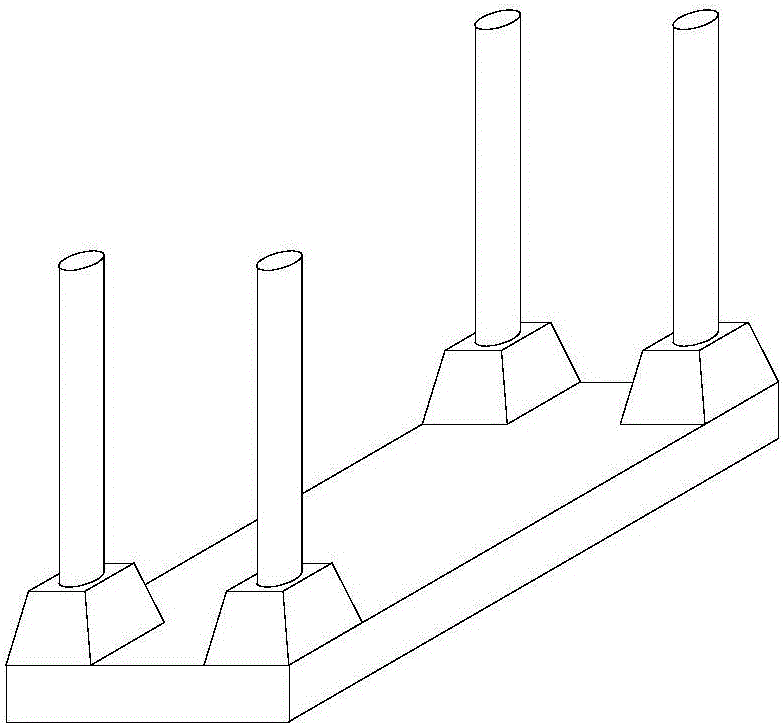

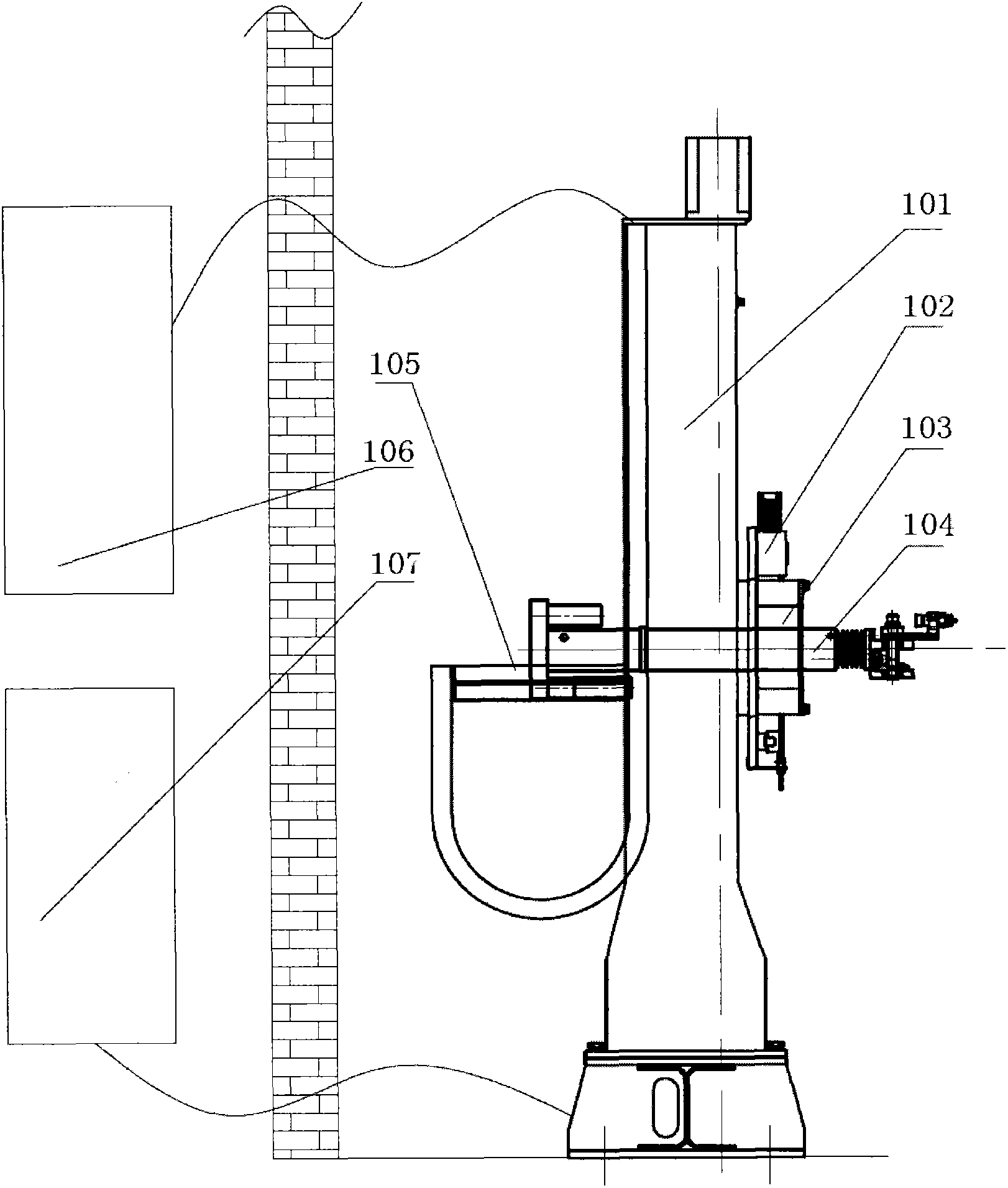

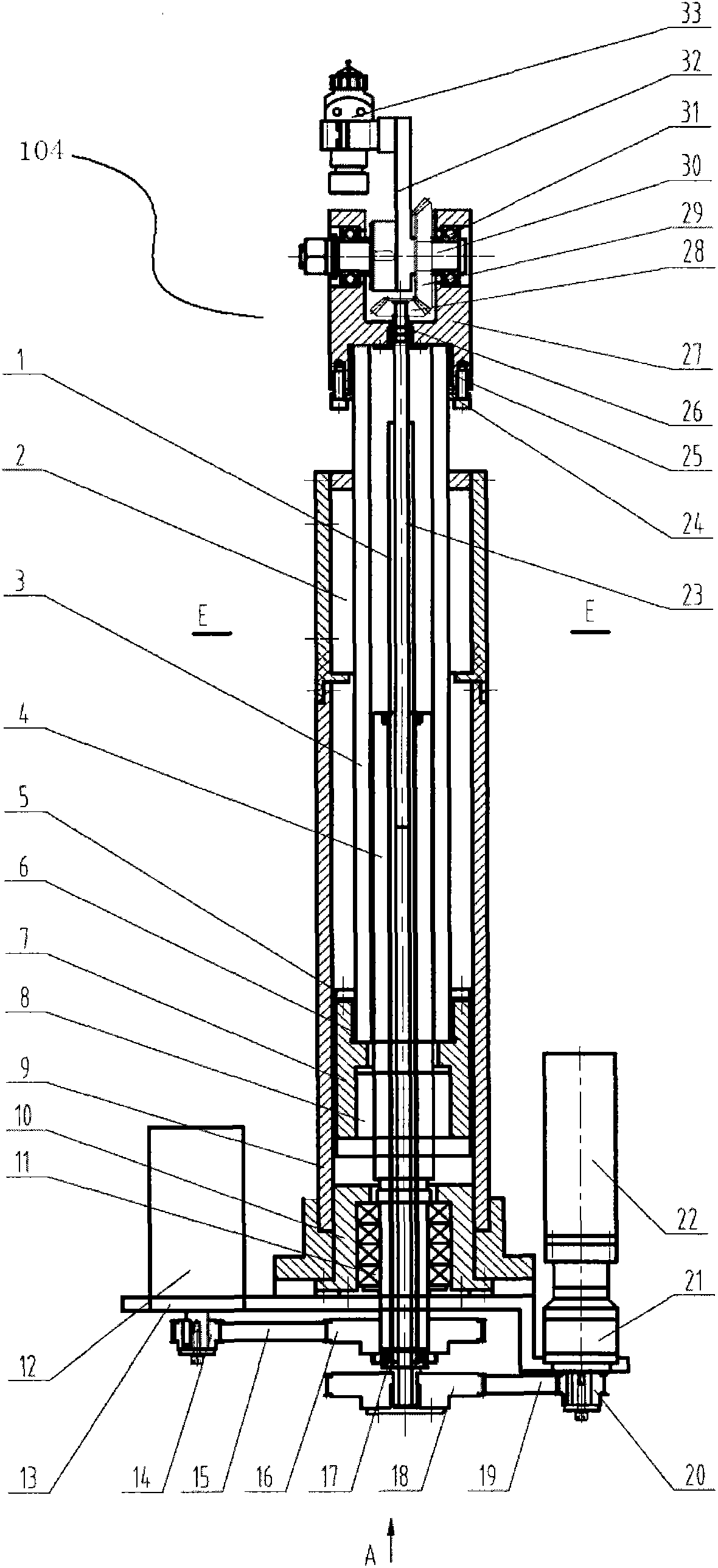

Hydraulic lifting system for ship

InactiveCN105731301AExtend your lifeHydraulic principle is clearServomotor componentsServomotorsHydraulic pumpOperability

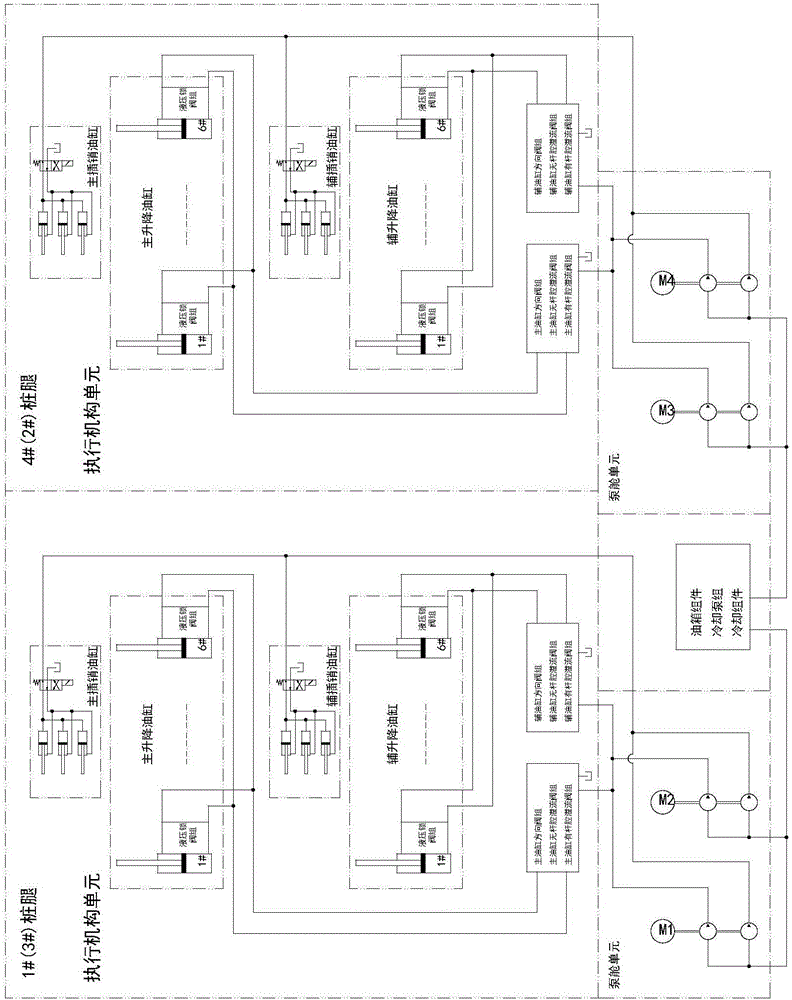

The invention discloses a hydraulic lifting system for a ship, and aims to facilitate monitoring in a lifting process. The hydraulic lifting system has the advantages that the operation is safe and reliable, the operability is high, and the cost is effectively reduced. According to the technical scheme, the whole ship is supported by four spud legs, that is, the ship body is fixed on the four spud legs; the ring beams of the spud legs are driven by a plurality of main lifting oil cylinders to perform rising and falling action synchronously, so as to life the whole ship; and the action of the oil cylinders is powered by two sets of hydraulic pump stations at the bow and stern of the ship.

Owner:SHANGHAI ZHENHUA HEAVY IND

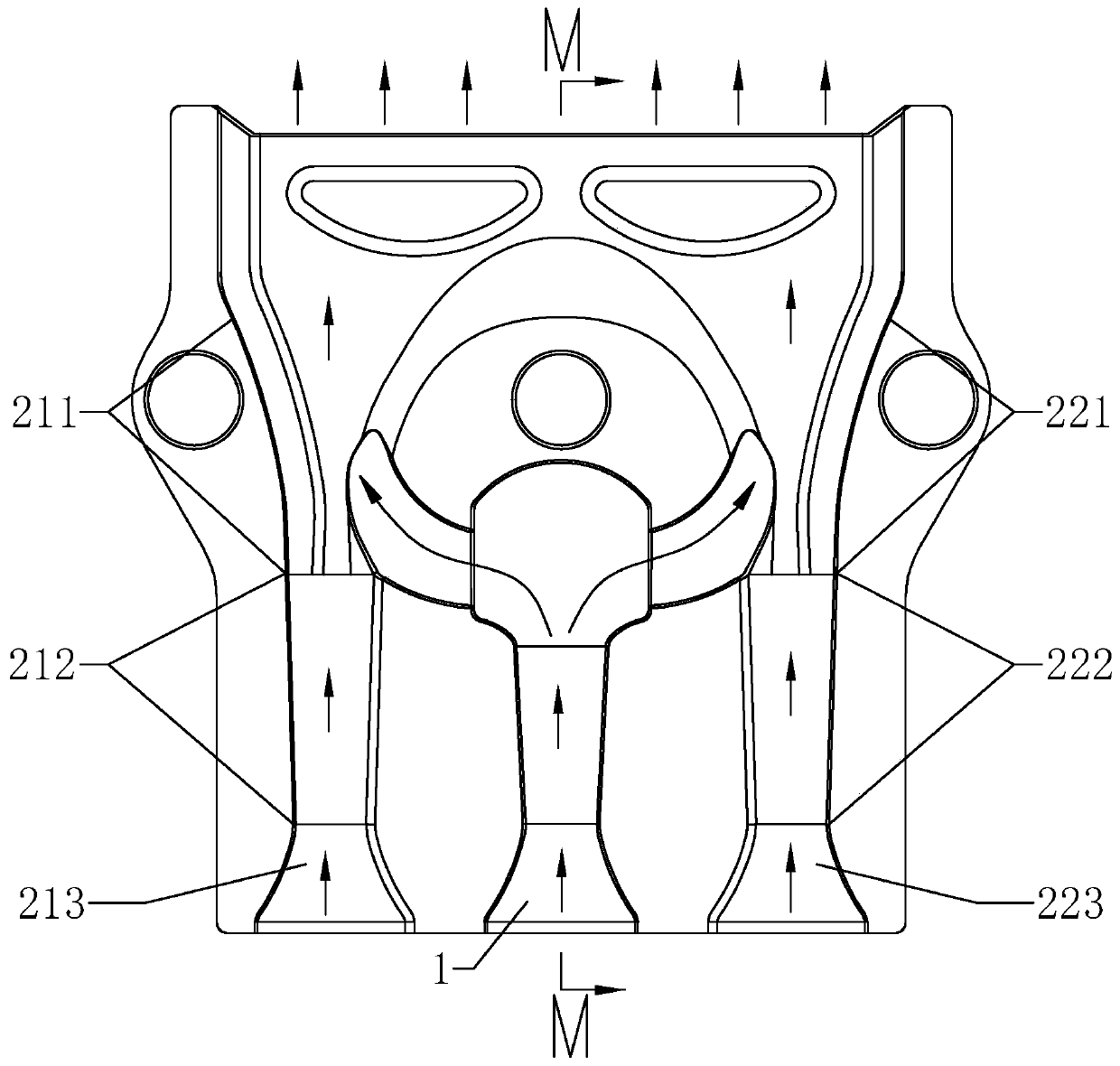

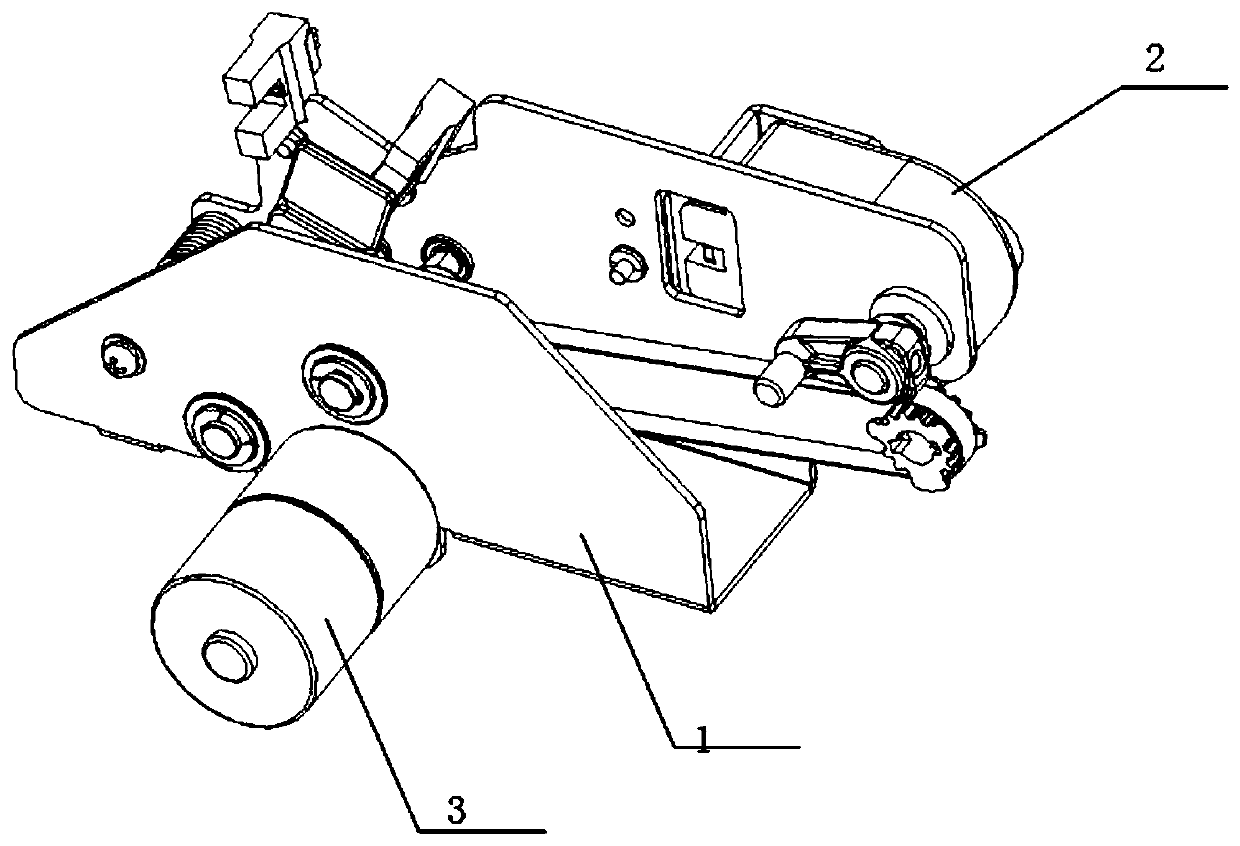

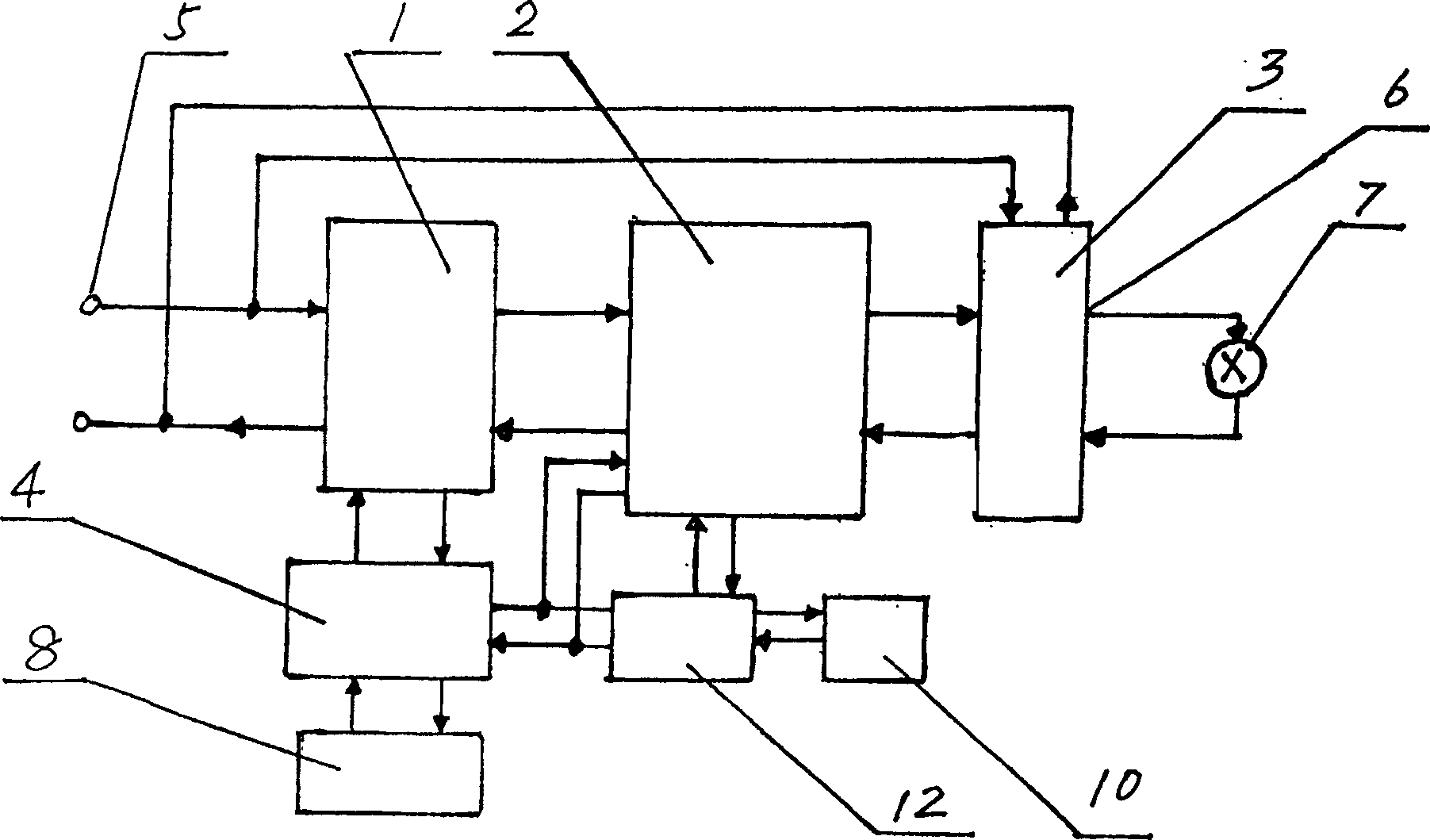

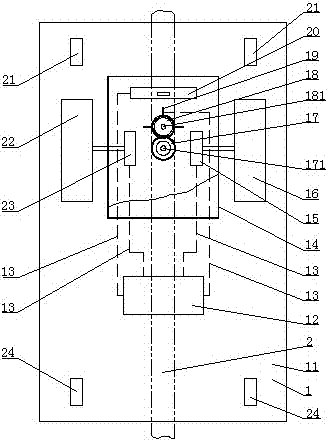

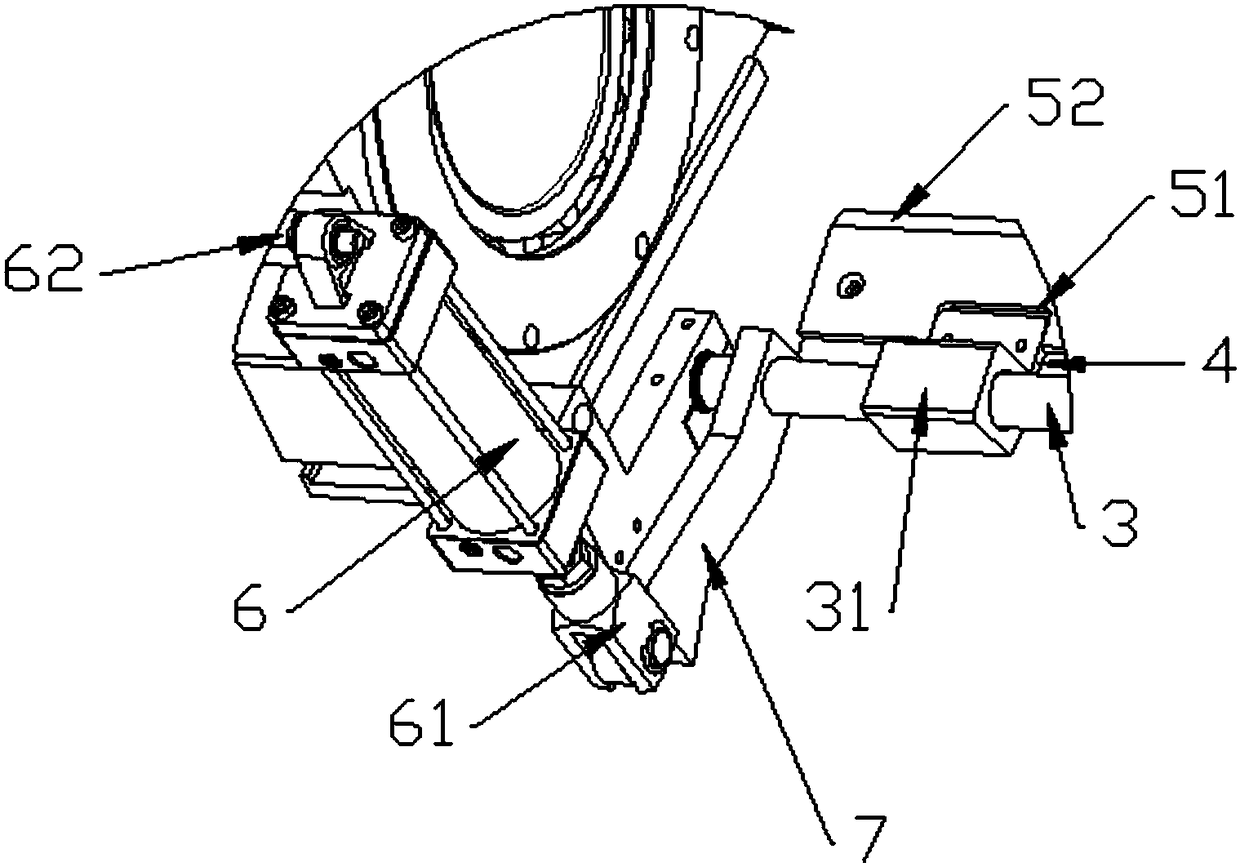

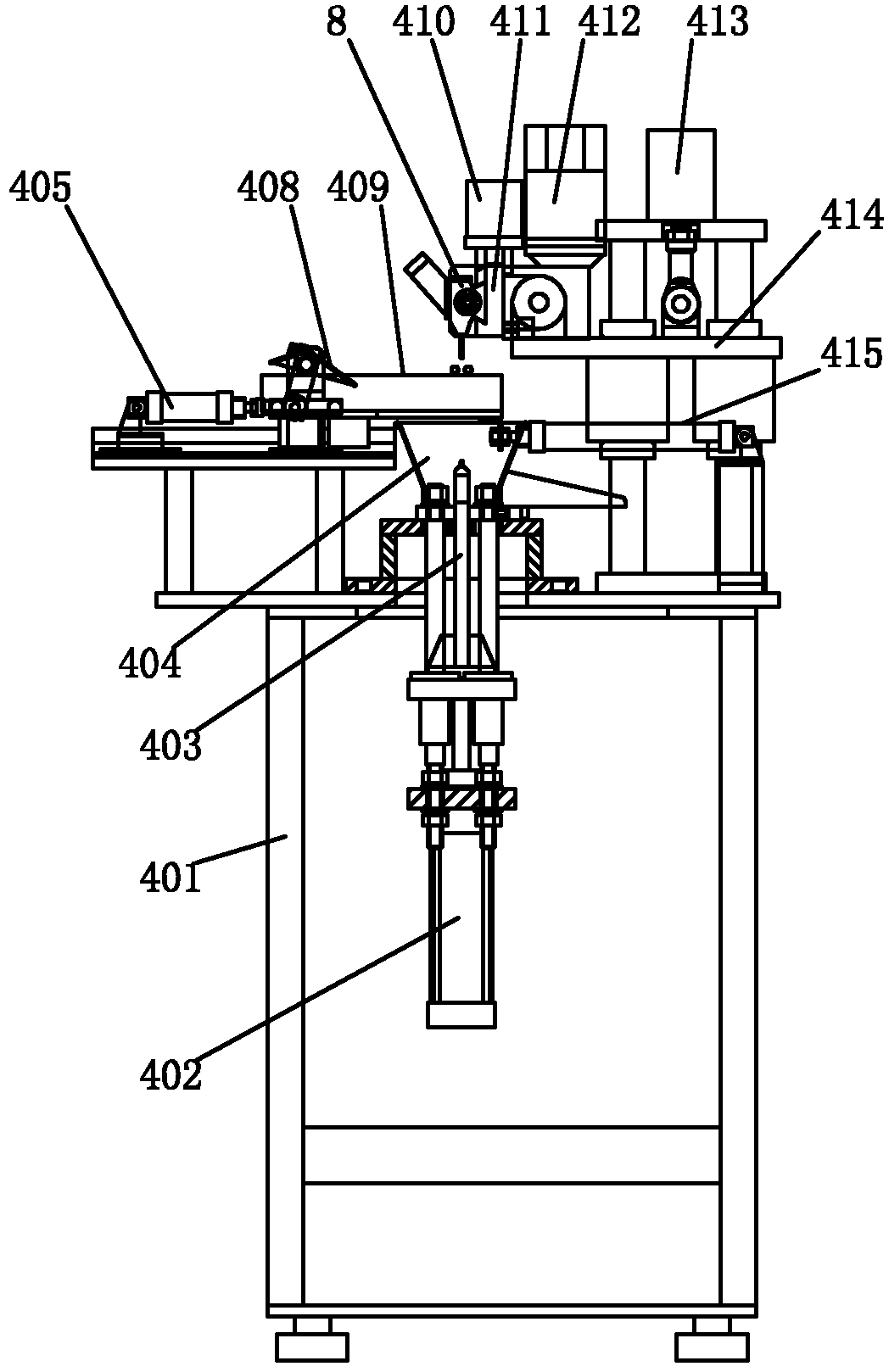

Robot arm stretching and swinging driving mechanism assembly

A robot arm stretching and swinging driving mechanism assembly comprises a stretching driving mechanism and a swinging driving mechanism; the stretching driving mechanism comprises an independent stretching driving motor and an independent stretching transmission mechanism; the swinging driving mechanism comprises an independent swinging driving motor and an independent swinging transmission shaft; the independent swinging transmission shaft is positioned at the center of the independent stretching transmission mechanism; the independent swinging transmission mechanism drives a robot arm swinging bracket to stretch in the axial direction; and the independent swinging transmission shaft drives an actuating mechanism fixed on a swinging bracket rotating shaft to swing. The two sets of independent driving motors and the two sets of transmission mechanisms, which are independent and related, are provided, and the two sets of driving mechanisms are both arranged on the robot arm, so that the purpose that the final controlled objects of the two set of independent driving mechanism are the same actuating mechanism can be achieved.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

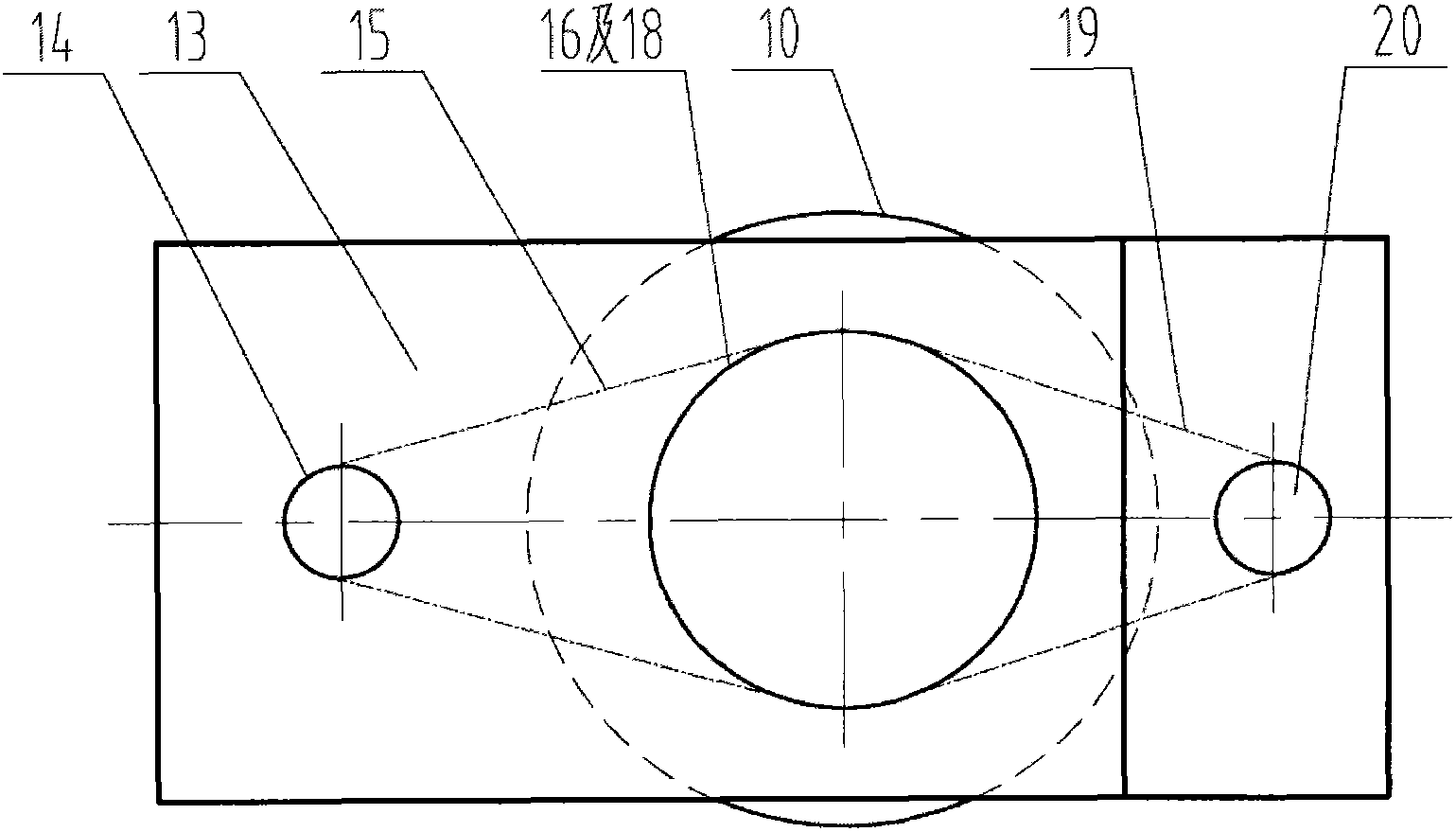

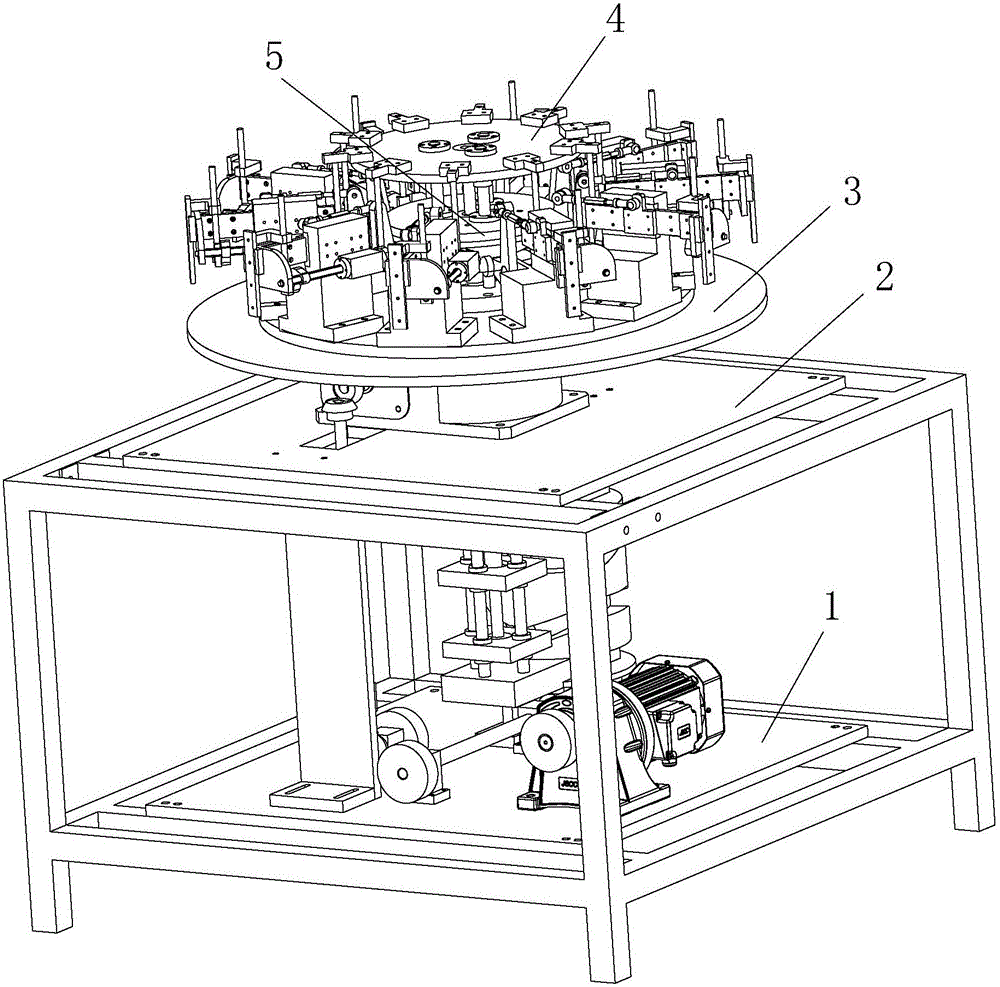

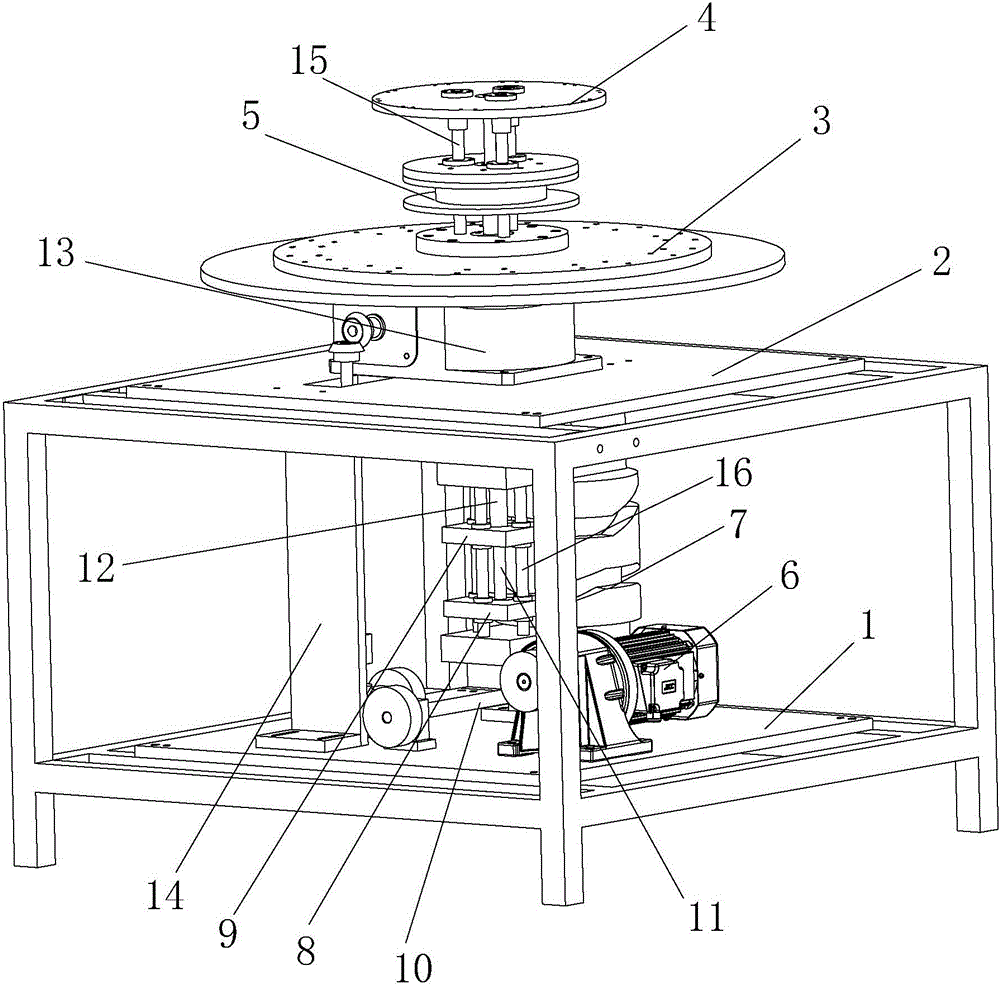

Mechanical assembling mechanism

The invention relates to a mechanical assembling mechanism which comprises a drive device and at least one material taking device. The drive device comprises a first chassis, a second chassis, a rotating disc, a first lifting disc, a second lifting disc, a motor, a first rotating shaft, a first transmission rod and a second transmission rod. The motor is in drive connection to the first rotating shaft and the rotating disc. A first guide groove and a second guide groove are developed in the outer surface of the first rotating shaft. A first connecting column is arranged at the lower end of the first transmission rod and inserted into the first guide groove. A second connecting column is arranged at the lower end of the second transmission rod and inserted into the second guide groove. The material taking device comprises a base, a rocker arm, a telescoping arm, a clamp base, a second rotating shaft and a clamp, wherein the second rotating shaft is in drive connection with the clamp base and penetrates the base, the second lifting disc is in drive connection with the rocker arm, and the first lifting disc is in drive connection with the second rotating shaft. The assembling mechanism is simple in structure, long in service life, low in fault rate, high in moving speed and high in precision, program control is easy, and the production cost is reduced.

Owner:东莞市钜升智能机械有限公司

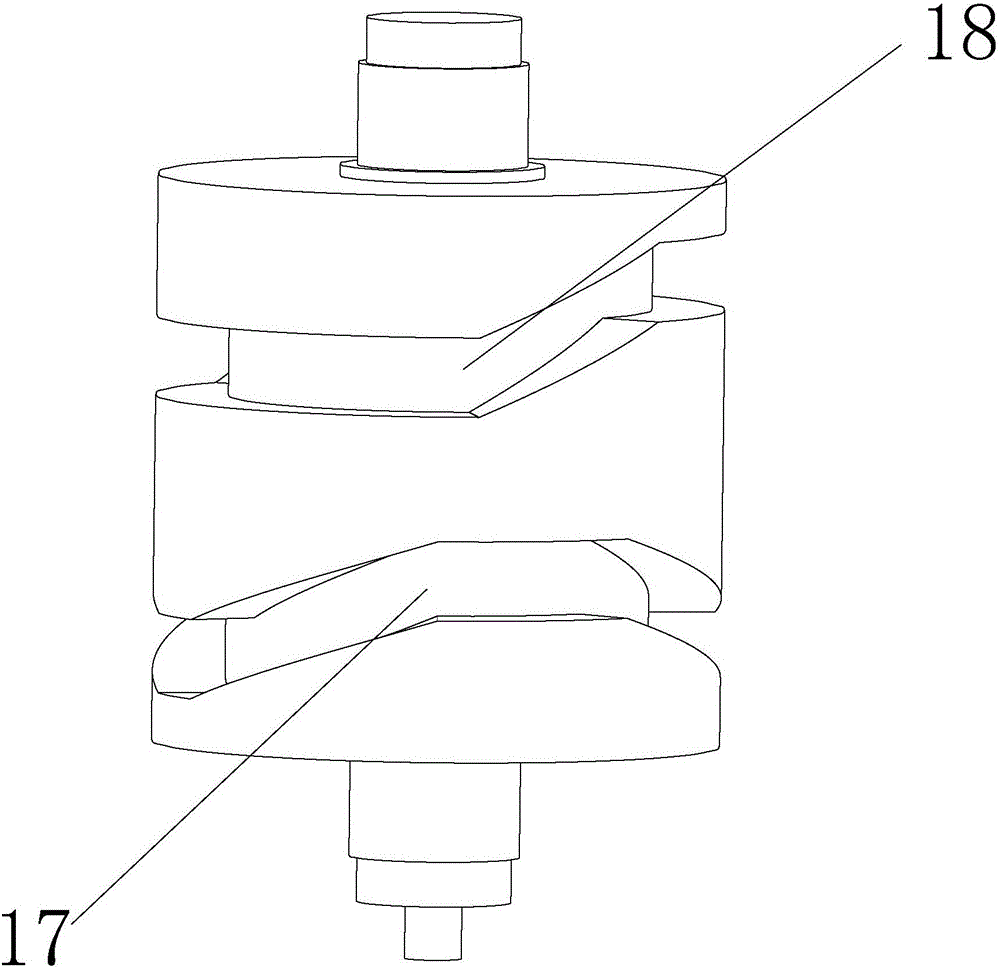

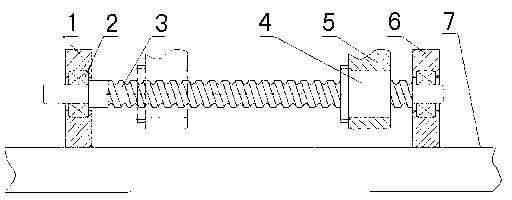

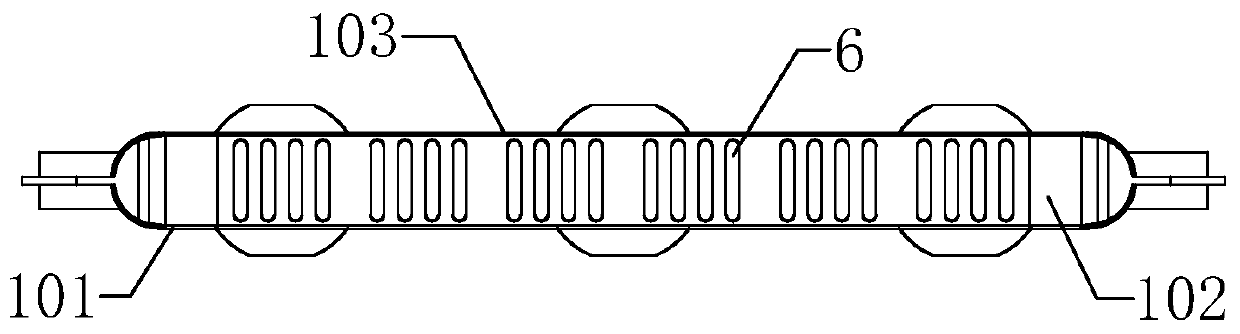

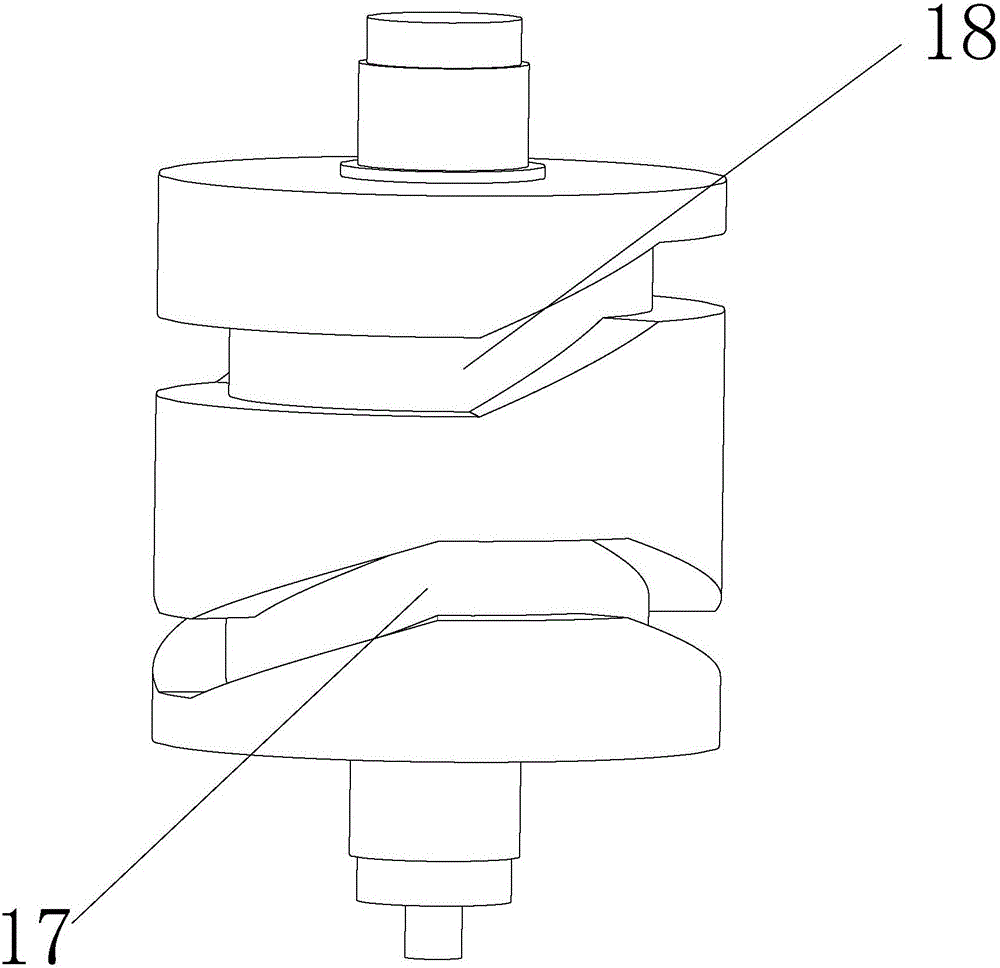

Transmission mechanism

InactiveCN103277472ALinear motion (opening and closing) speed increasedRealize self-lubricationGearingPower-operated mechanismLocking mechanismEngineering

A three-freedom-degree transmission mechanism comprises a helical pair, a revolute pair and a cylindrical pair. The axis of the helical pair is perpendicular to the axis of the revolute pair, and the axis of the revolute pair is parallel to the axis of the cylindrical pair. The revolute pair comprises a support (7), a movable sliding block (5), the helical pair (3), a nut (4), a left limiting block (1) and a right limiting block (6). The left limiting block (1) and the right limiting block (6) are fixedly arranged on the support (7), and the helical pair (3) is provided with the movable sliding block (5). The transmission mechanism is characterized in that the helical pair (3) mounted on the support (7) and the revolute pair can form 0-degree to 180-degree intersection angles through the movable sliding block (5). According to the transmission mechanism, under the condition of identical number of rotation of a screw rod, the speed of the straight line motion (opening and closing) of the nut (a door leaf) is improved. The mechanical locking of a vehicle door is achieved without another set of mechanical locking mechanism. The transmission mechanism is simple, the motion procedures of unlocking and locking are removed, procedure control is simplified, and two fault hazards are eliminated.

Owner:JIANGSU YABAO AUTO PARTS

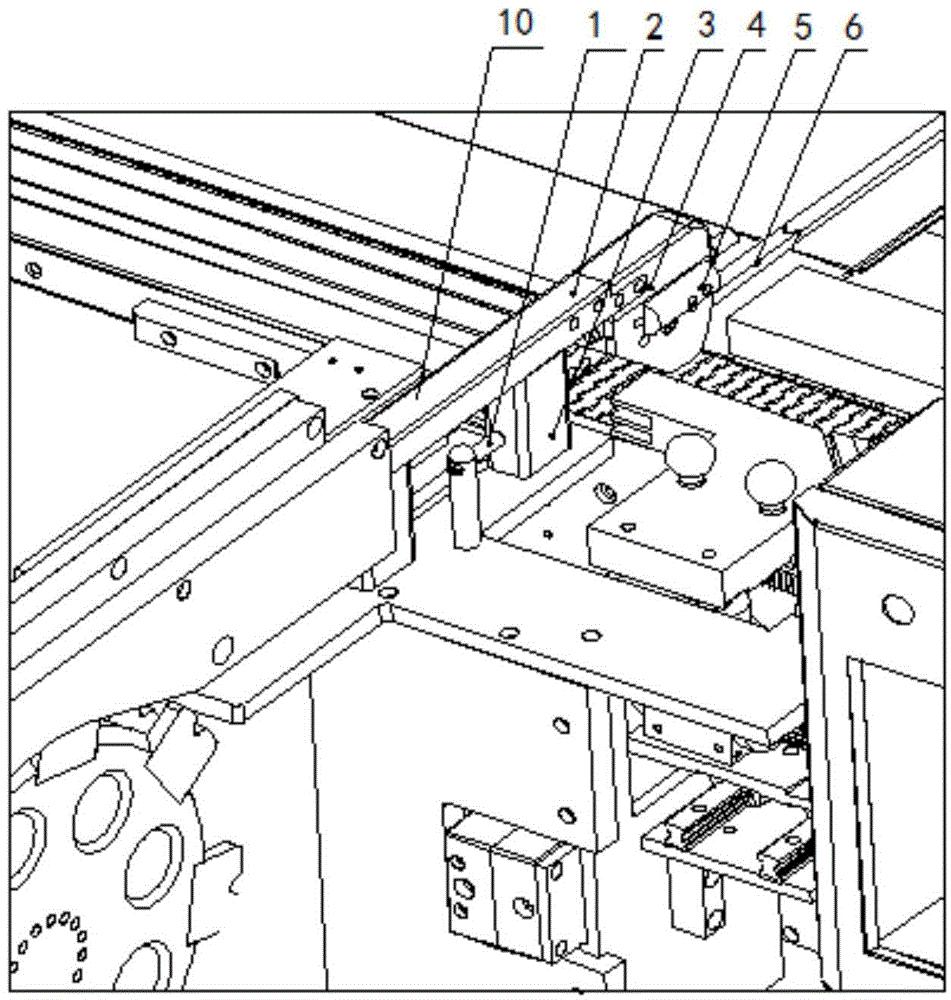

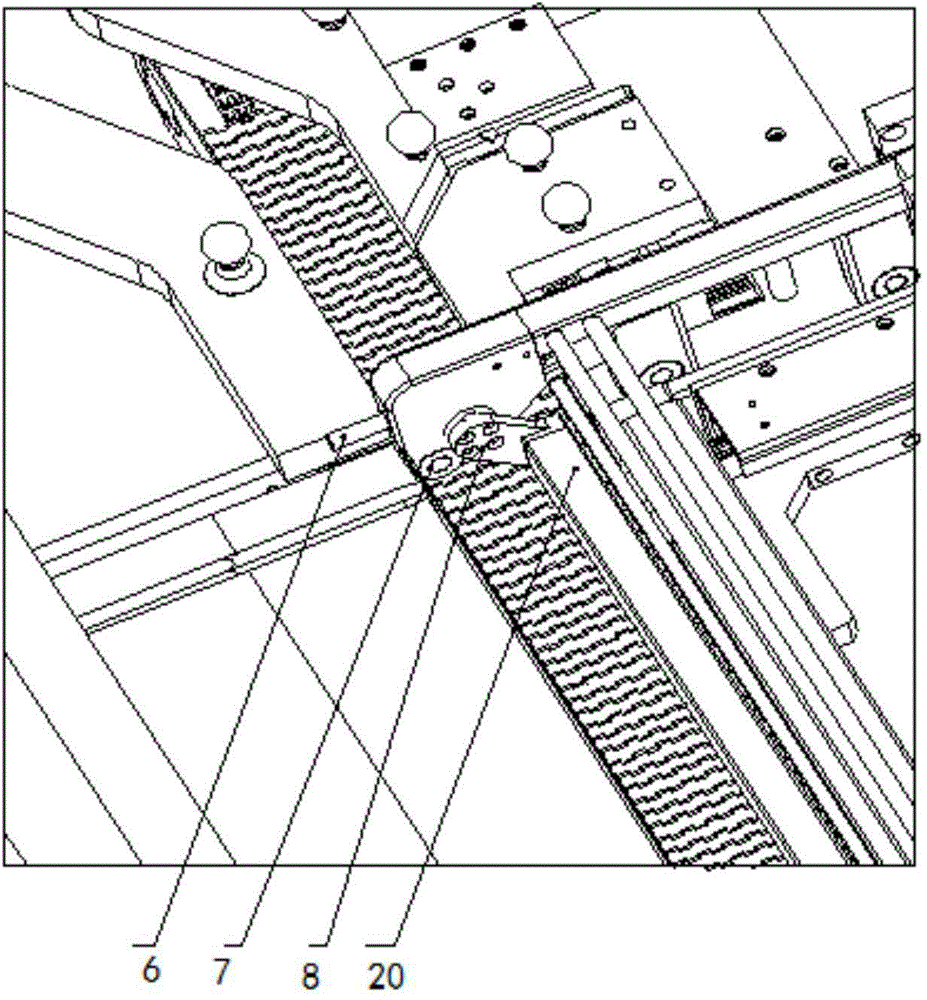

Guider for flaky object conveying

ActiveCN106097567ASimple structureSimple structural designCoin/currency accepting devicesArticle feedersEngineeringElectromagnet

The invention discloses a guider for flaky object conveying, comprising a reversing blade assembly, a power drive assembly matching the reversing blade assembly, and a channel arranged outside the reversing blade assembly. The power drive assembly comprises a power drive assembly frame, a two-way electromagnet assembly and a power motor assembly. The two-way electromagnet assembly and the power motor assembly are arranged on the power drive assembly frame. The two-way electromagnet assembly and the power motor assembly drive the power drive assembly to rotate and reverse. The reversing blade assembly and the channel form a conveying channel when the reversing blade assembly rotates and reverses. The guider for flaky object conveying has the advantages of reasonable and simple structure design, low production cost, easy-to-control precision, and easy operation.

Owner:广州智清电子科技有限公司

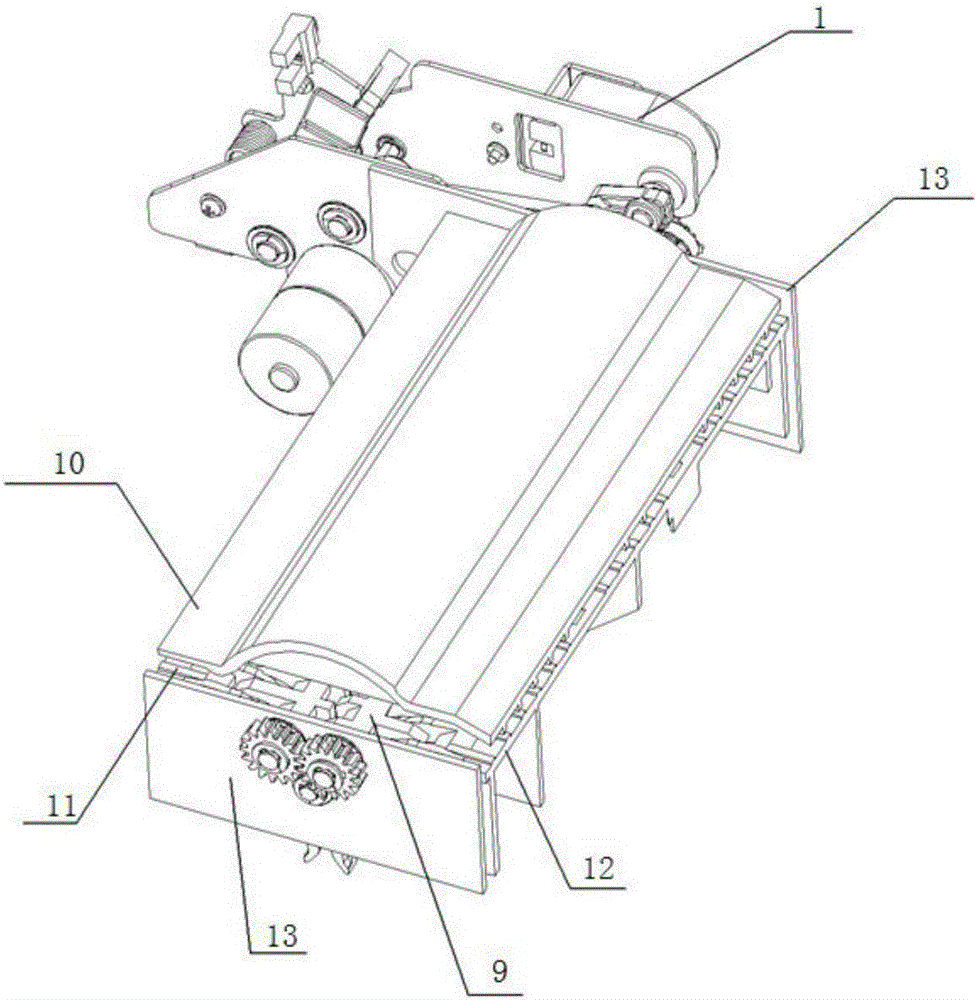

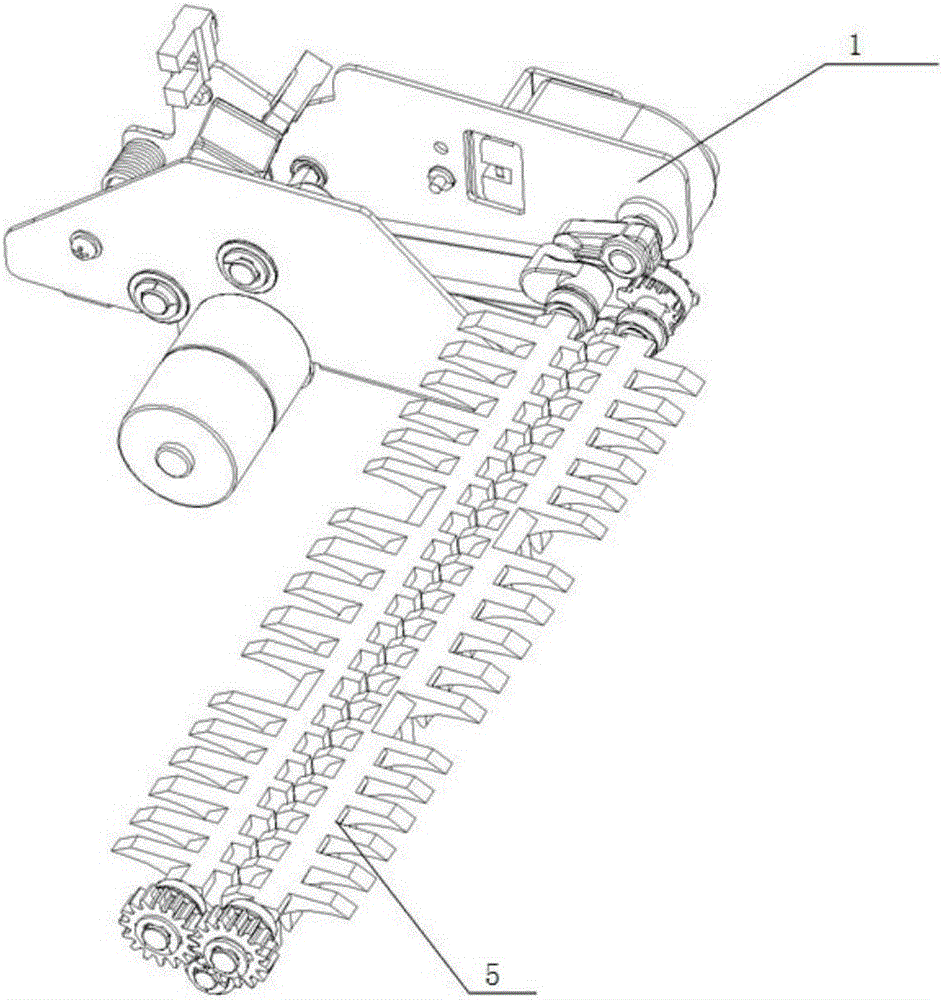

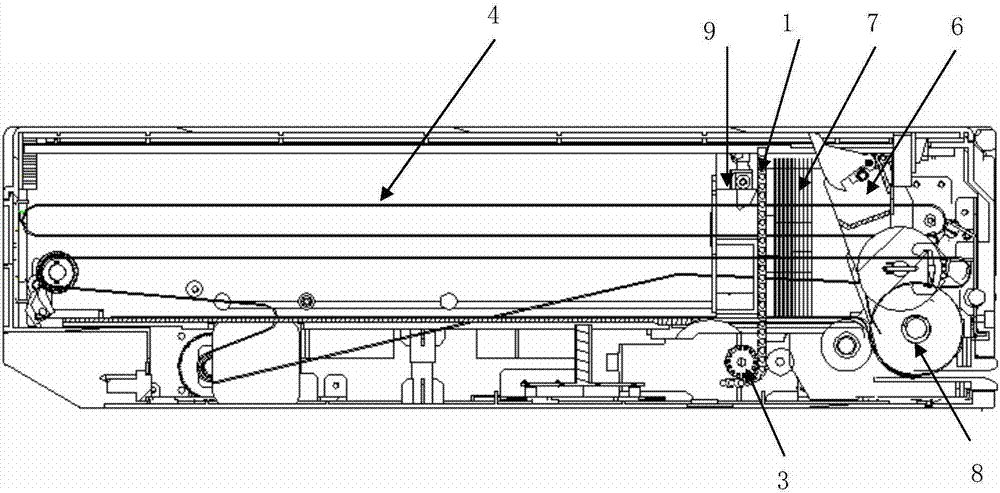

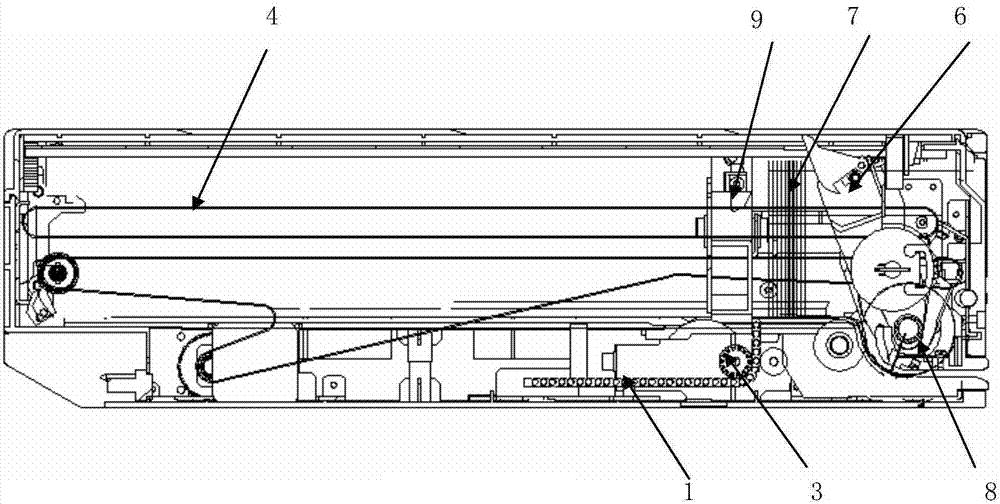

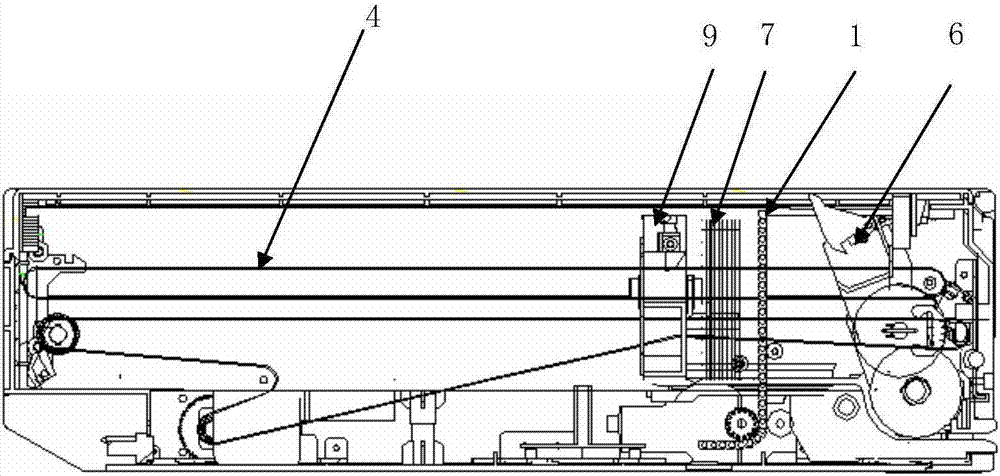

Circulating currency box with temporary storage function and working method thereof

InactiveCN107221072ADoes not affect normal withdrawalImprove stabilityComplete banking machinesCoin/currency accepting devicesGear driveElectric machinery

The invention belongs to the technical field of automatic teller machines, and particularly relates to a circulating currency box with a temporary storage function. The circulating currency box with the temporary storage function comprises a temporary storage pushing plate arranged in the currency box; the temporary storage pushing plate has a track-type structure; two ends of the temporary storage pushing plate are in sliding match with a guiding groove arranged at the inner side of the currency box; the bottom part of the currency box is provided with a lifting motor and a gear driven by the lifting motor; the gear is engaged with the temporary storage pushing plate, and thus, vertical movement of the temporary storage pushing plate is realized. Independent movement control on the pushing plate, the temporary storage pushing plate mechanism and an upper currency grinding and separating mechanism is realized, program control is simplified, the structure is simple, and the mounting and the maintenance are facilitated.

Owner:CASHWAY FINTECH CO LTD

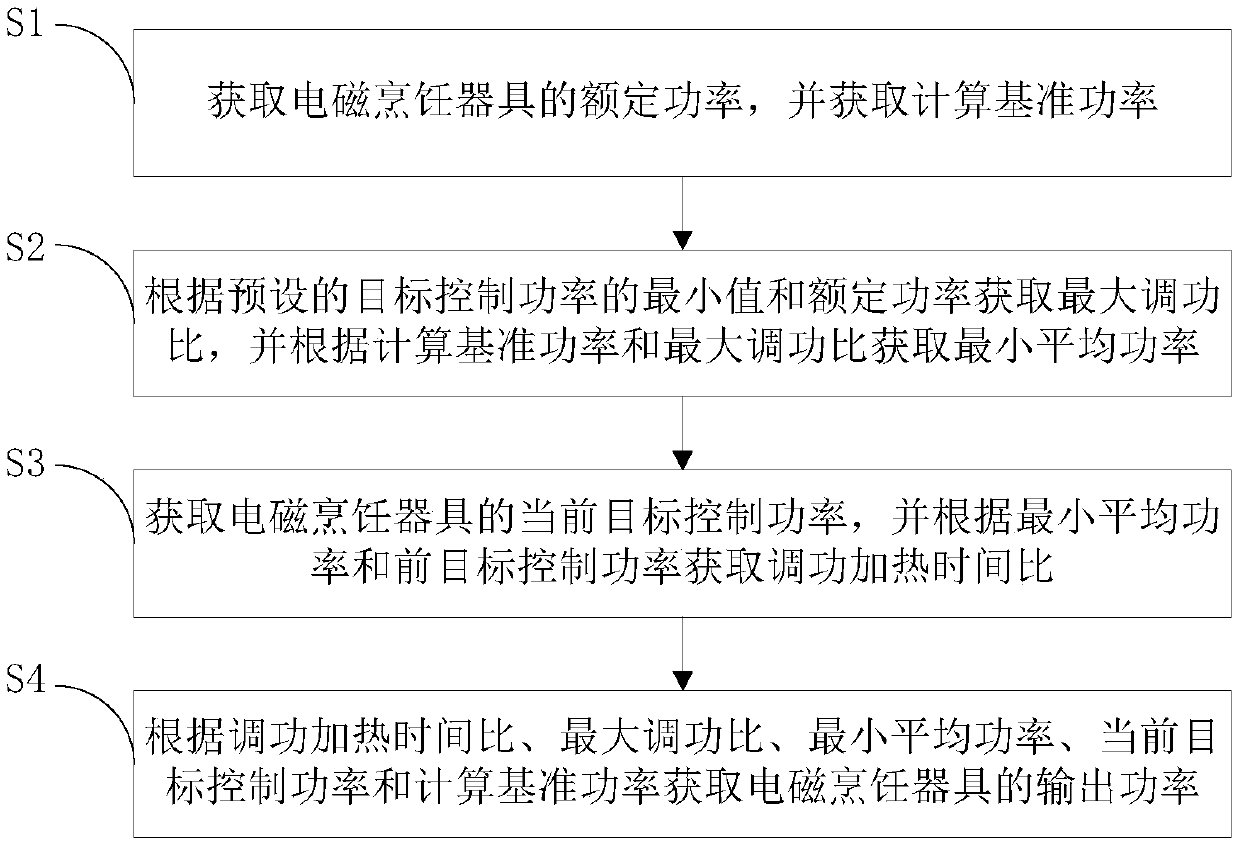

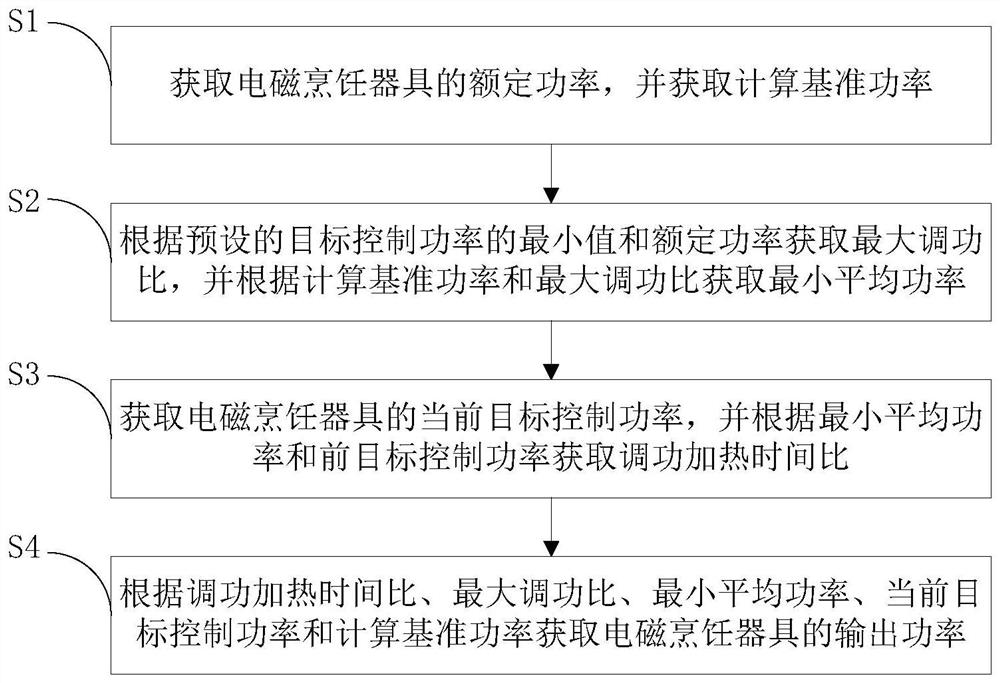

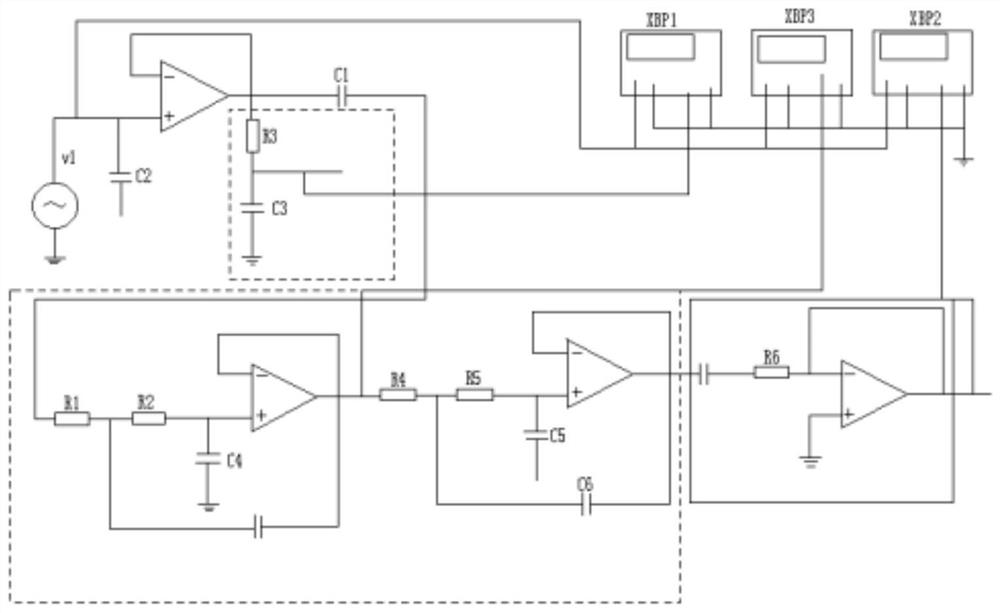

Electromagnetic cooking appliance as well as method for calculating output power of electromagnetic cooking appliance

The invention discloses an electromagnetic cooking appliance as well as a method for calculating the output power of the electromagnetic cooking appliance. The method comprises the following steps: acquiring the rated power of the electromagnetic cooking appliance and acquiring calculation reference power; acquiring the maximal modulation power ratio according to the minimum value of the preset target control power and the rated power, and acquiring the minimal average power according to the calculation reference power and the maximal modulation power ratio; acquiring the current target control power of the electromagnetic cooking appliance and acquiring the modulation power heating time ratio according to the minimal average power and the current target control power; according to the modulation power heating time ratio, the maximal modulation power ratio, the minimal average power, the current target control power and the calculation reference power, acquiring the output power of theelectromagnetic cooking appliance. According to the calculation method, the output power of the electromagnetic cooking appliance can be directly acquired, data lockup is avoided and the program is simple to control.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

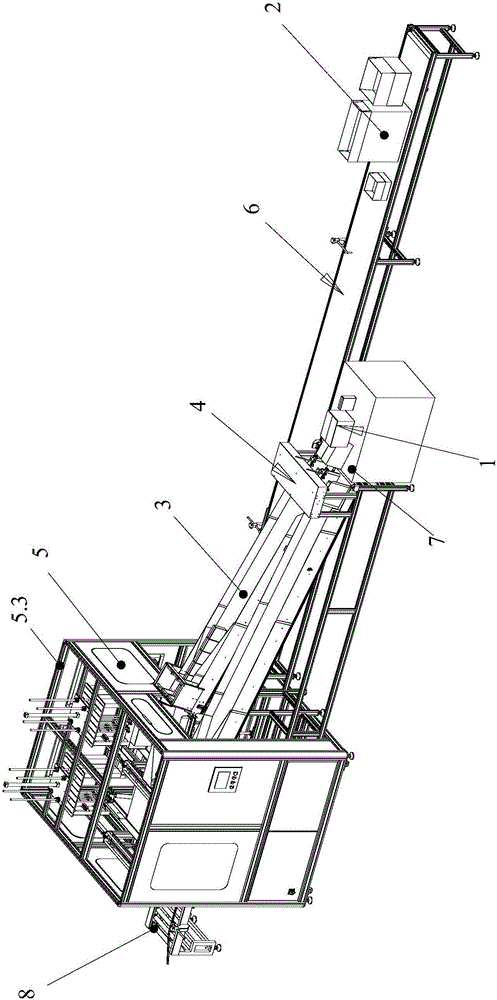

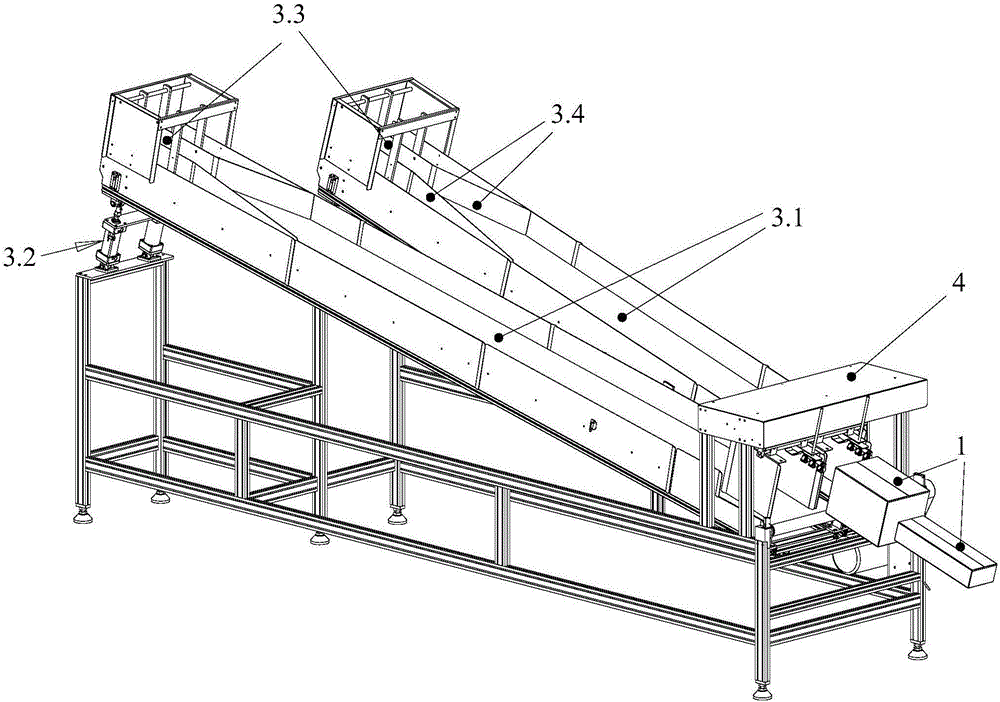

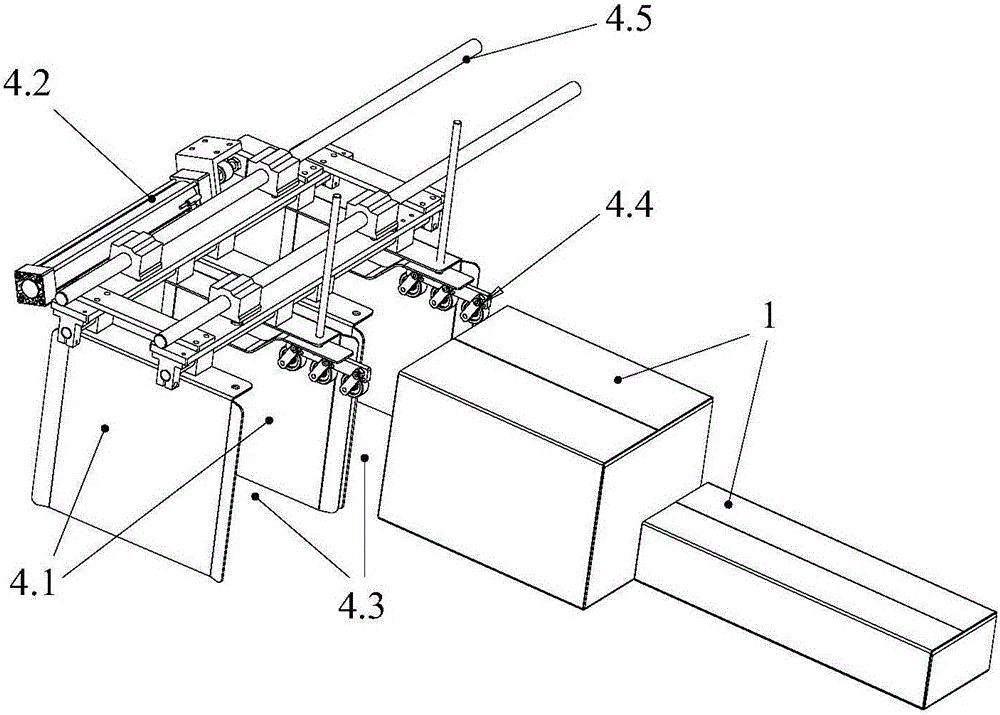

Automatic casing method for paper boxes

The invention provides an automatic casing method for paper boxes. The automatic casing method comprises a paper box dividing process, a paper box conveying process, an outer case conveying process and a casing process. According to the paper box conveying process, M conveying channels are arranged; according to the paper box dividing process, single conveyed paper boxes are subjected to movable dividing and conveyed to the M conveying channels arranged in the paper box conveying process; according to the casing process, the paper boxes conveyed through the paper box conveying process are formed into lines / columns and then layers line-by-line / column-by-column according to preset arrangements, the arranged whole layer of paper boxes are packaged into outer cases conveyed through the outer case conveying process, and the paper boxes are packaged into the outer cases layer by layer in an overlapping mode through the descending of the outer cases; in the outer case conveying process, after the outer cases are conveyed to the casing process, the paper boxes are packaged into the outer cases in an outer case descending mode, and the outer cases are conveyed out after the paper boxes are packaged into the outer cases. According to the method, rapid and stable casing can be achieved, and the production efficiency and the accuracy of paper box casing are improved.

Owner:FOSHAN UNIVERSITY

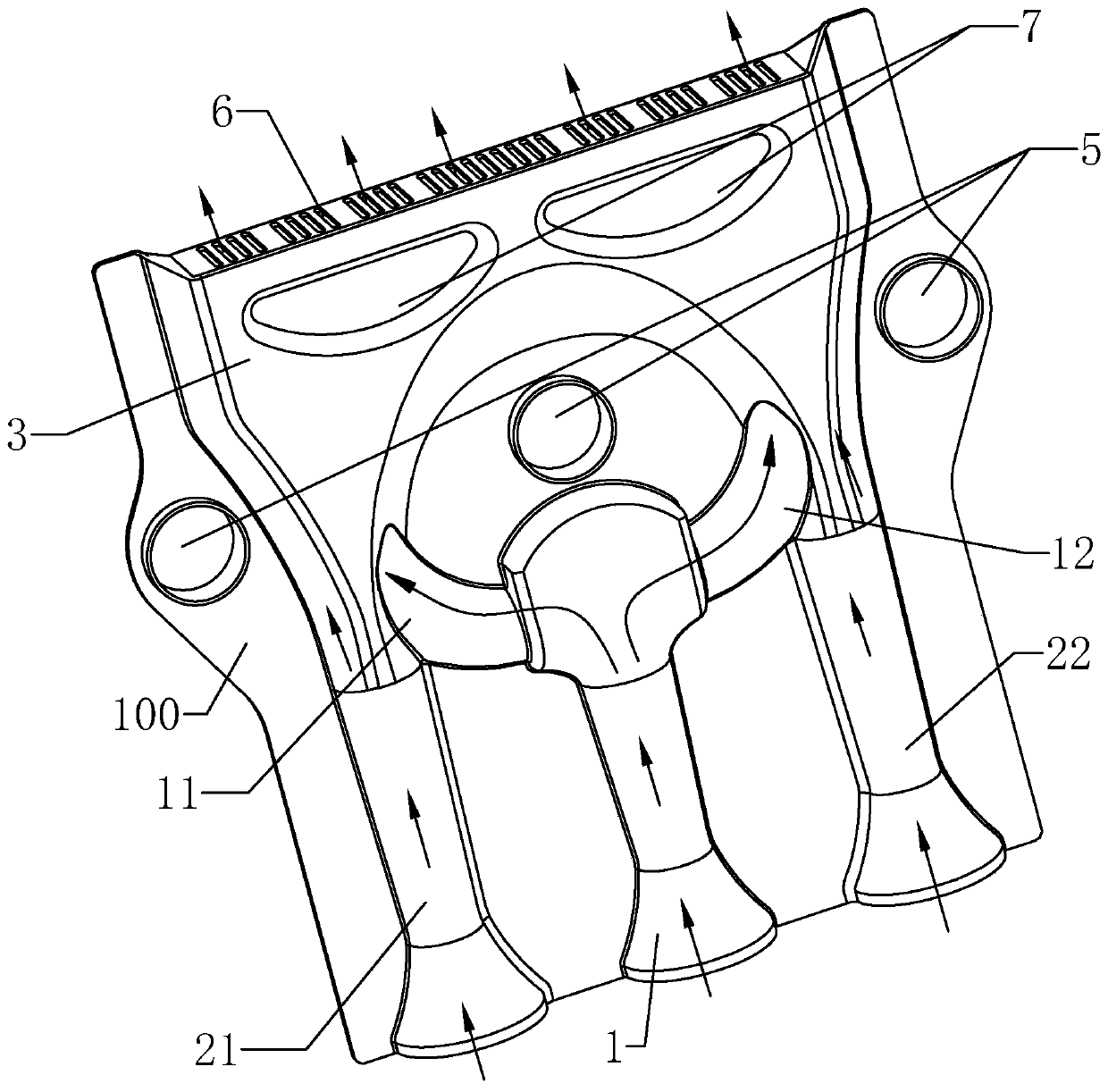

Low-nitrogen burner and fuel gas device thereof

InactiveCN110296400AFull combustion utilizationAchieve emissionsGaseous fuel burnerCombustorLow nitrogen

The invention relates to a low-nitrogen burner and a fuel gas device thereof. The low-nitrogen combustor comprises a shell, wherein an injection channel, an air supply channel, a diversion channel anda diffusion mixing cavity are arranged in the shell, the shell is further provided with a plurality of water flow channels which are arranged in the thickness direction in a penetrating manner; the gas inlet of the injection channel is used for introducing fuel gas and air, the air outlet end of the injection channel is in communication with the air supply channel through the diversion channel, an air inlet of the air supply channel is used for introducing air, an air outlet of the air supply channel is in communication with the diffusion mixing cavity, and the top of the shell is provided with a fire outlet communicating with the diffusion mixing cavity. According to the low-nitrogen burner and the fuel gas device thereof, the emission of the low nitrogen oxide can be effectively realized, the structure is relatively simple, and the control is facilitated.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

Electric proportional pressure valve

PendingCN112797185APrevent leakageAvoid enteringOperating means/releasing devices for valvesMultiple way valvesLoop controlControl system

The invention relates to the technical field of proportional pressure valves, in particular to an electric proportional pressure valve. The electric proportional pressure valve comprises a valve body, a valve seat, a valve element, a proportional electromagnet, a fixed cover and an elastic element, wherein the electric proportional pressure valve has a first working state, a second working state and a third working state. The design that the fixed cover is matched with the valve element is ingeniously utilized, so that the single proportional electromagnet can enable the electric proportional pressure valve to be freely switched among the three working states. The electric proportional pressure valve has the advantages that the structure is simple and reliable, the failure rate is low, the cost is low, the service life can be prolonged, and the harsh application environment of a vehicle can be adapted; and the proportional electromagnet directly drives the valve element to act, so that the control precision is high and the response is fast; and the closed-loop control over pressure can be achieved by means of air pressure logic, so that the power consumption of the proportional electromagnet can be effectively reduced, meanwhile the development difficulty of a control system is reduced, program control is simple and easy to implement, and the market prospect is good.

Owner:环路科技(常州)有限公司

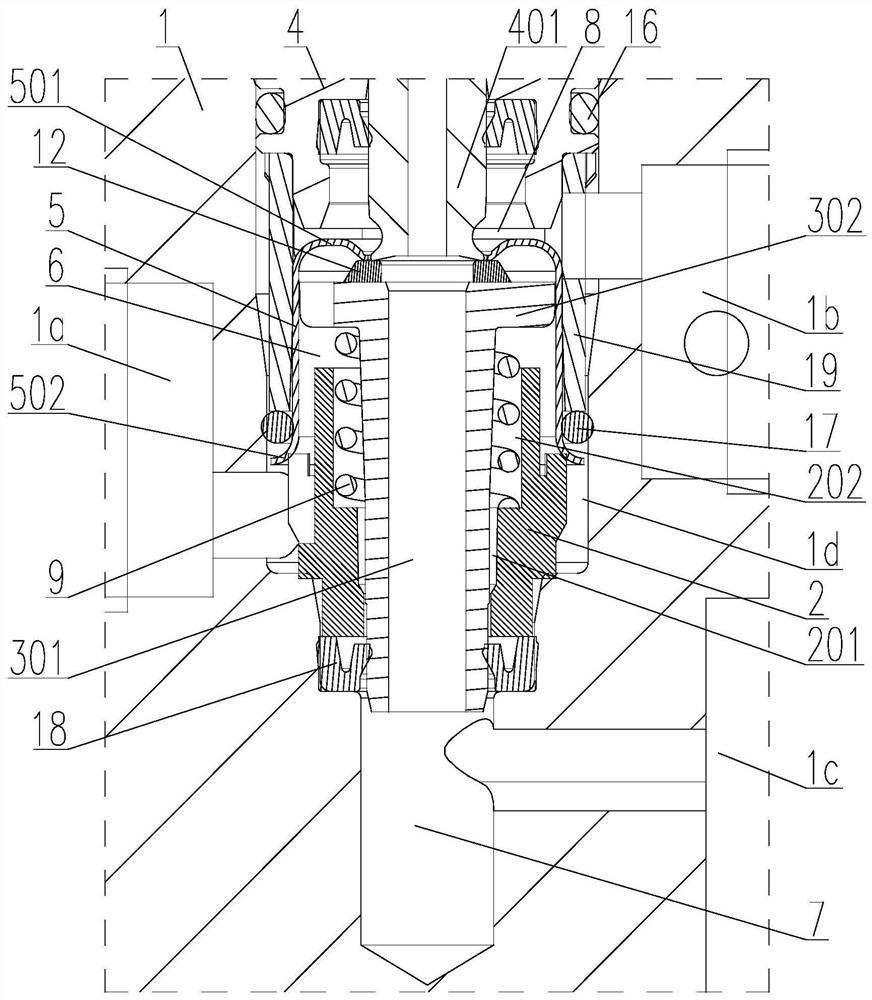

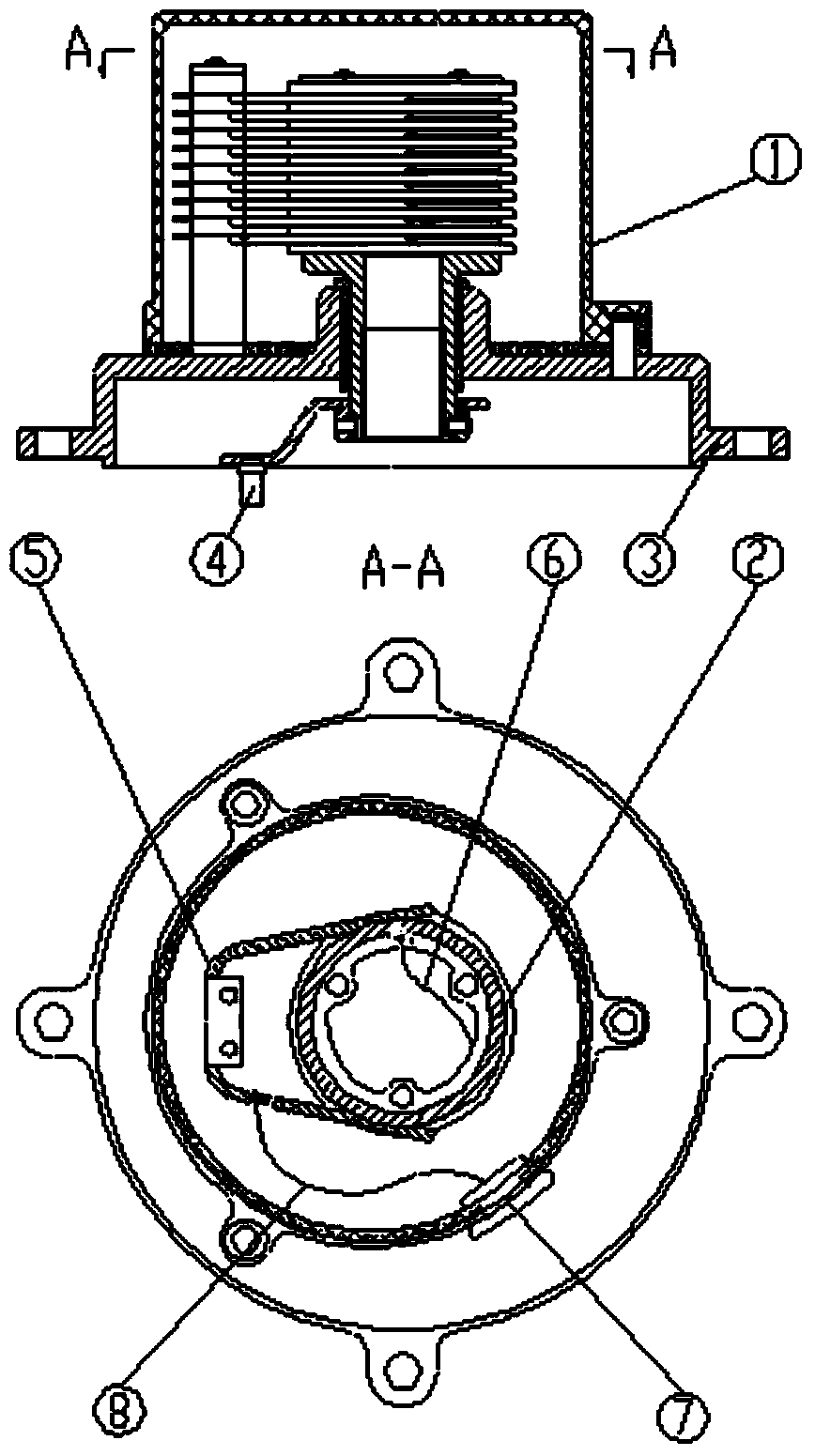

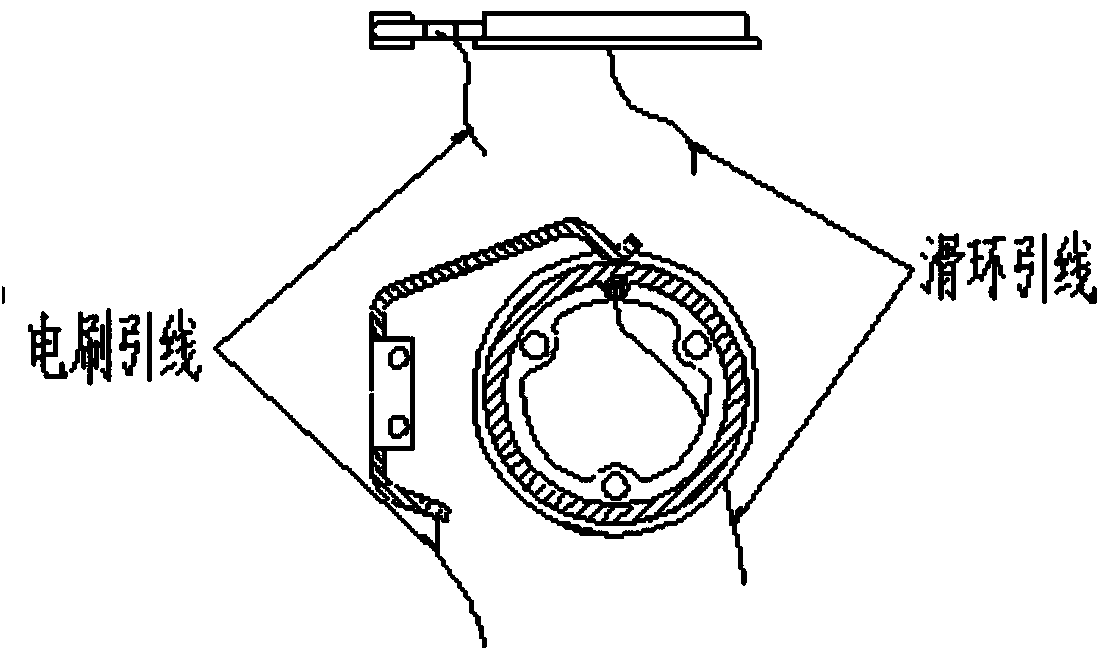

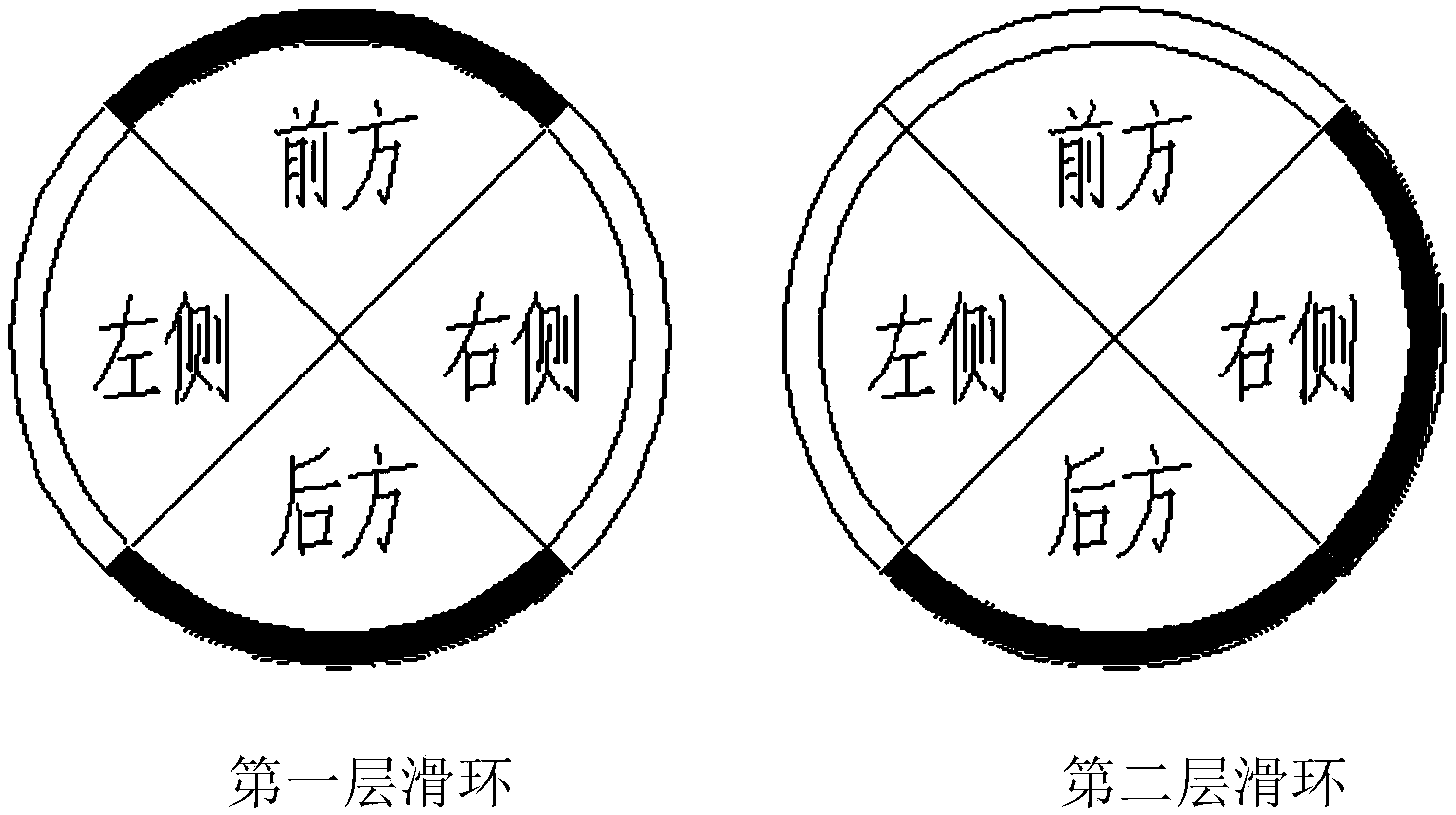

Rotating region detection device, system and detection method

InactiveCN104030162ASimple program controlEasy to transformLoad-engaging elementsElectrical conductorEngineering

The invention belongs to the technical field of the mechanical detection, and particularly relates to rotating region detection device, system and detection method. The rotating region detection device comprises a first brush body, a second brush body, a first layer of slide ring and a second layer of slide ring; the two layers of slide rings and the two layers of brush bodies simultaneously slide relatively; the first layer of slide ring is in single-point contact with the first brush body, the second layer of slide ring is in single-point contact with the second brush body, the first layer of slide ring and the second layer of slide ring are respectively of a structure consisting of conductor parts and insulator parts, which are alternately arranged, and the structure of the first layer of slide ring is different from that of the second layer of slide ring. By adopting the device, the technical problem for detecting the rotating region under the situation that no additional sensors such as an approaching switch or an encoder are installed can be solved.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE

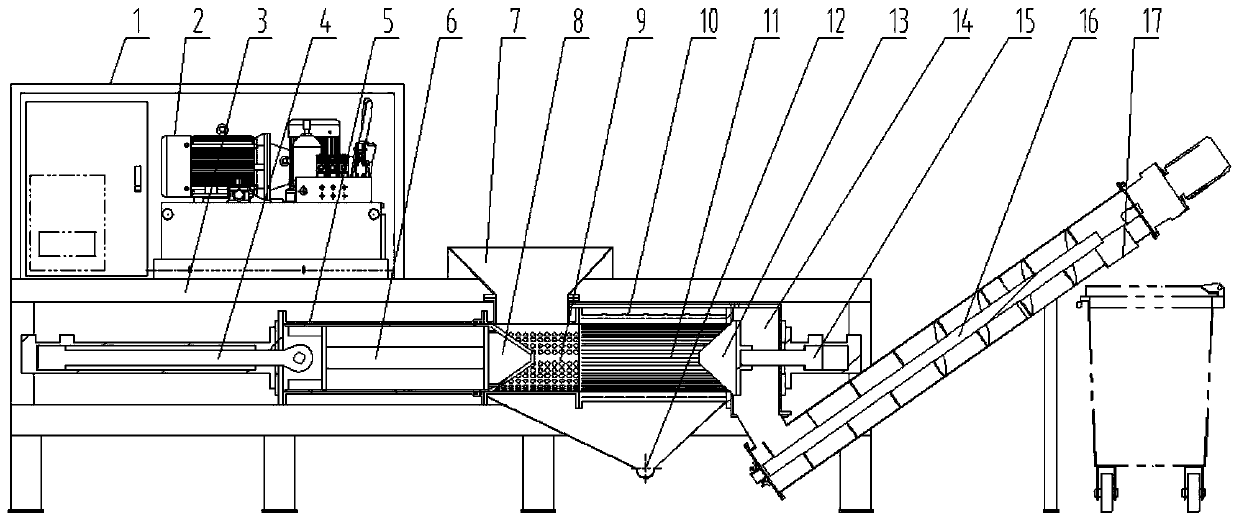

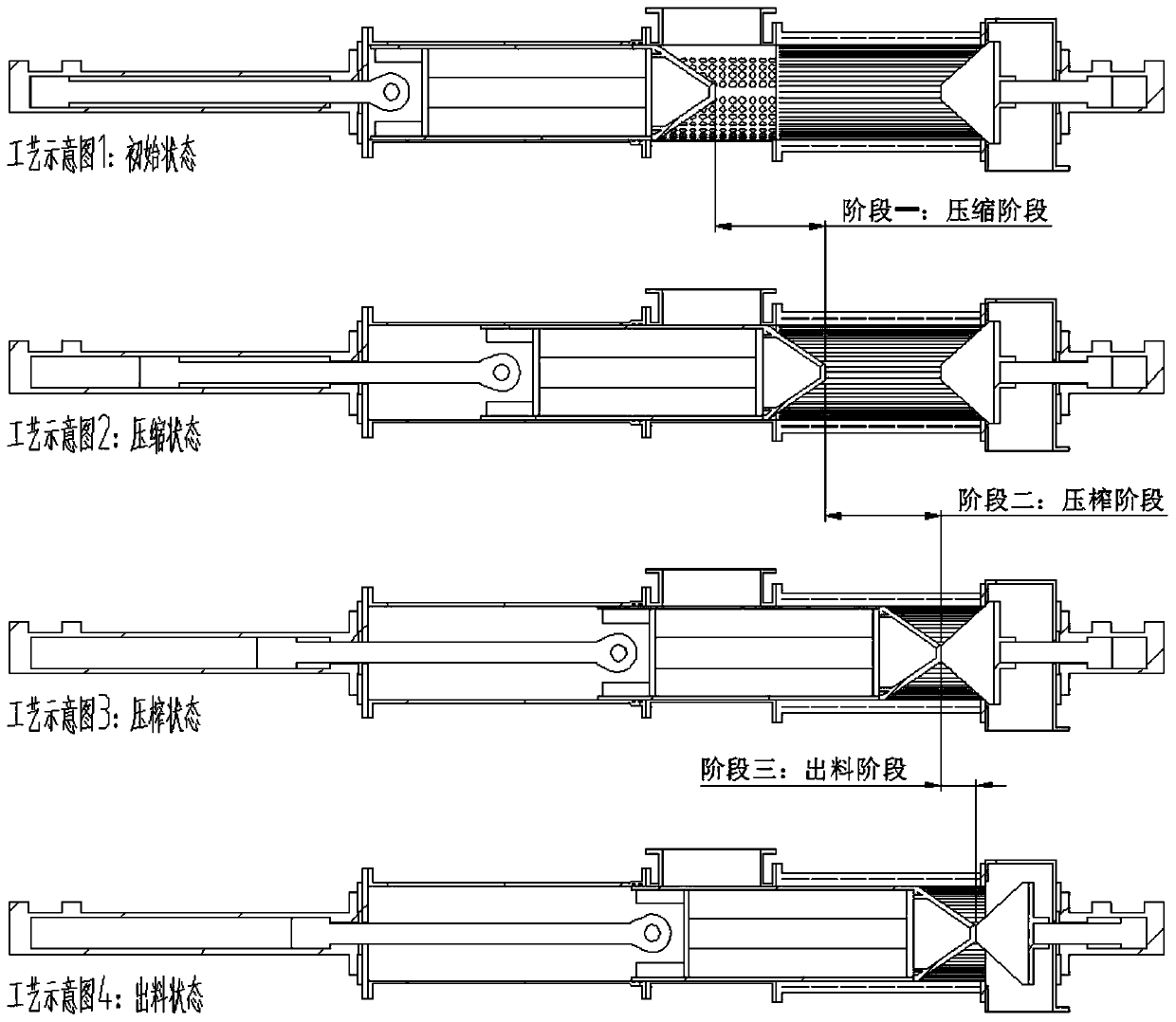

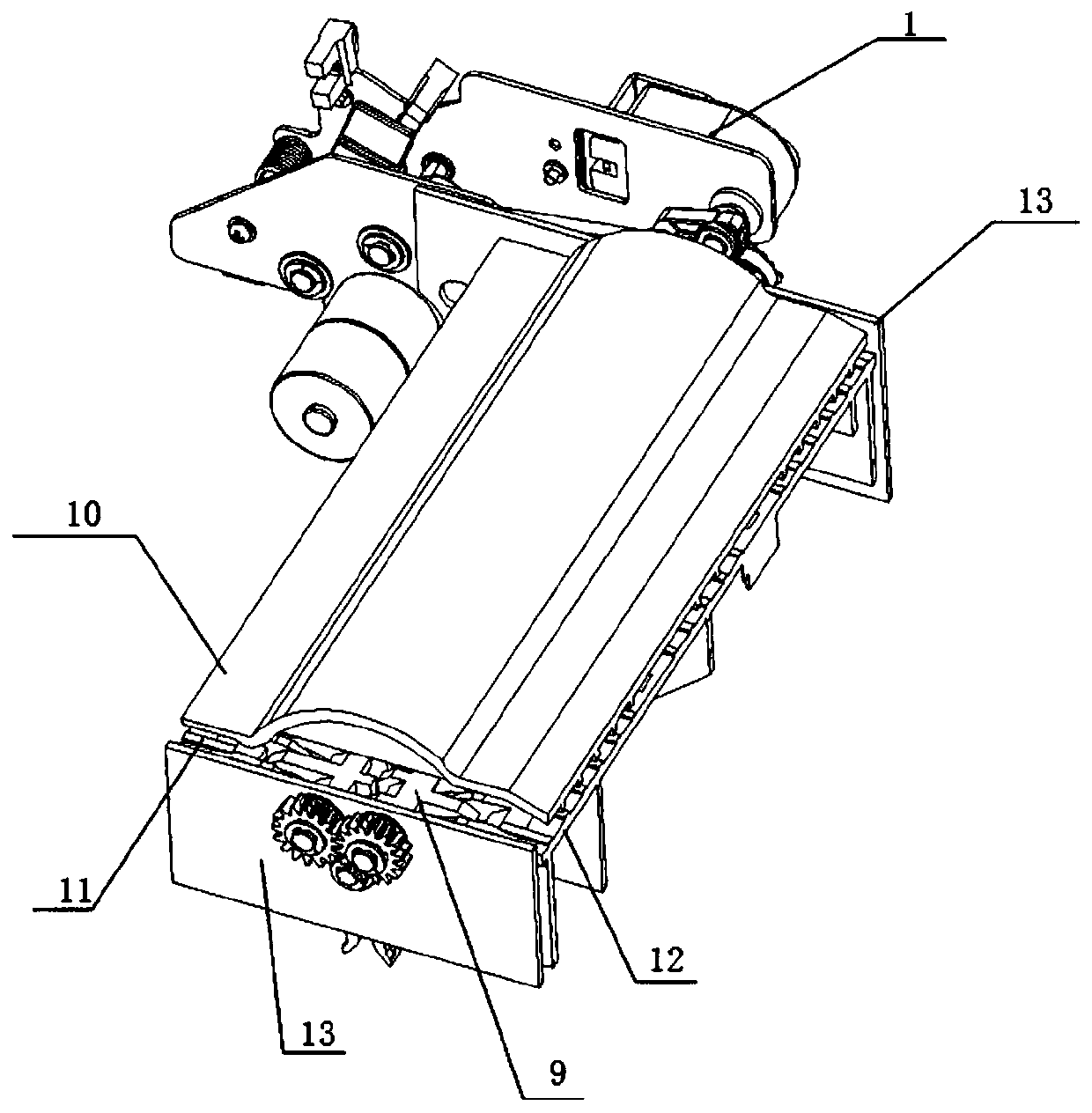

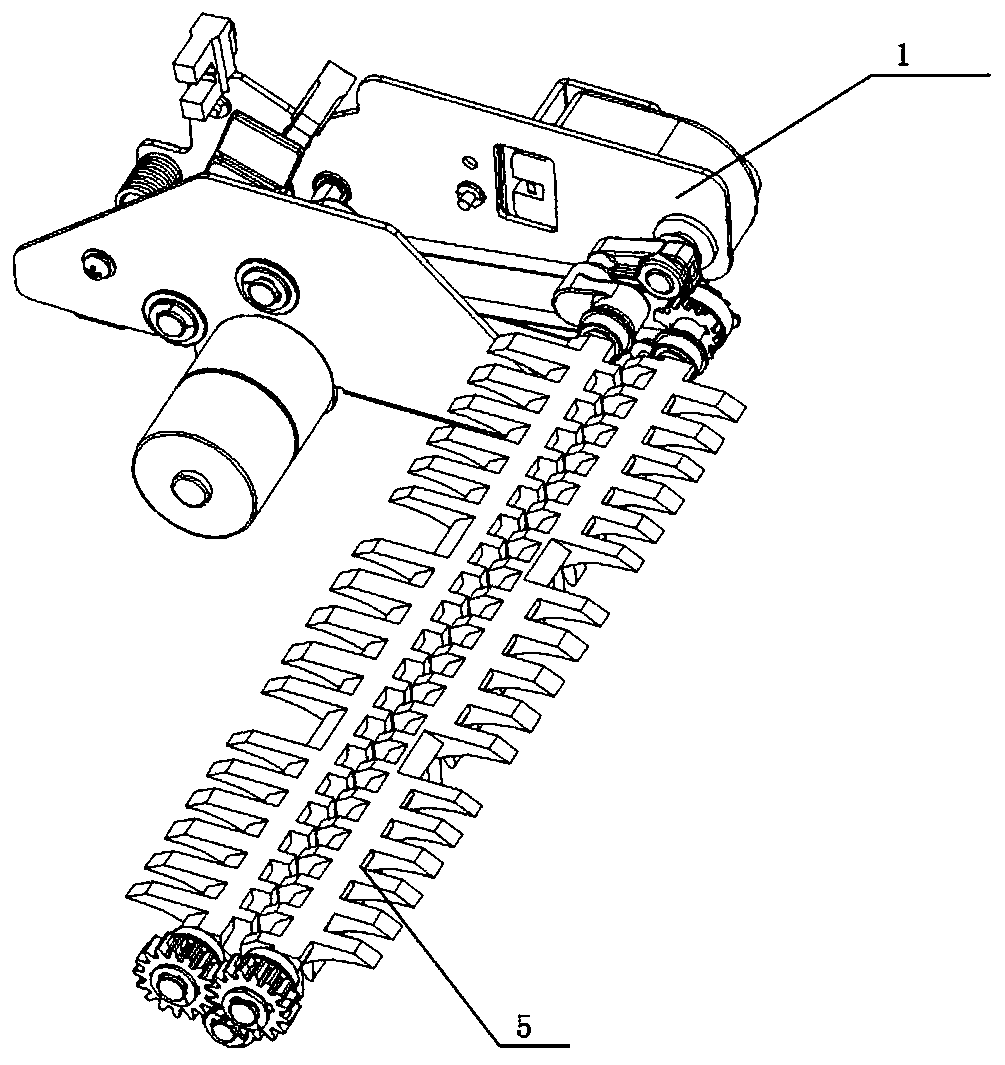

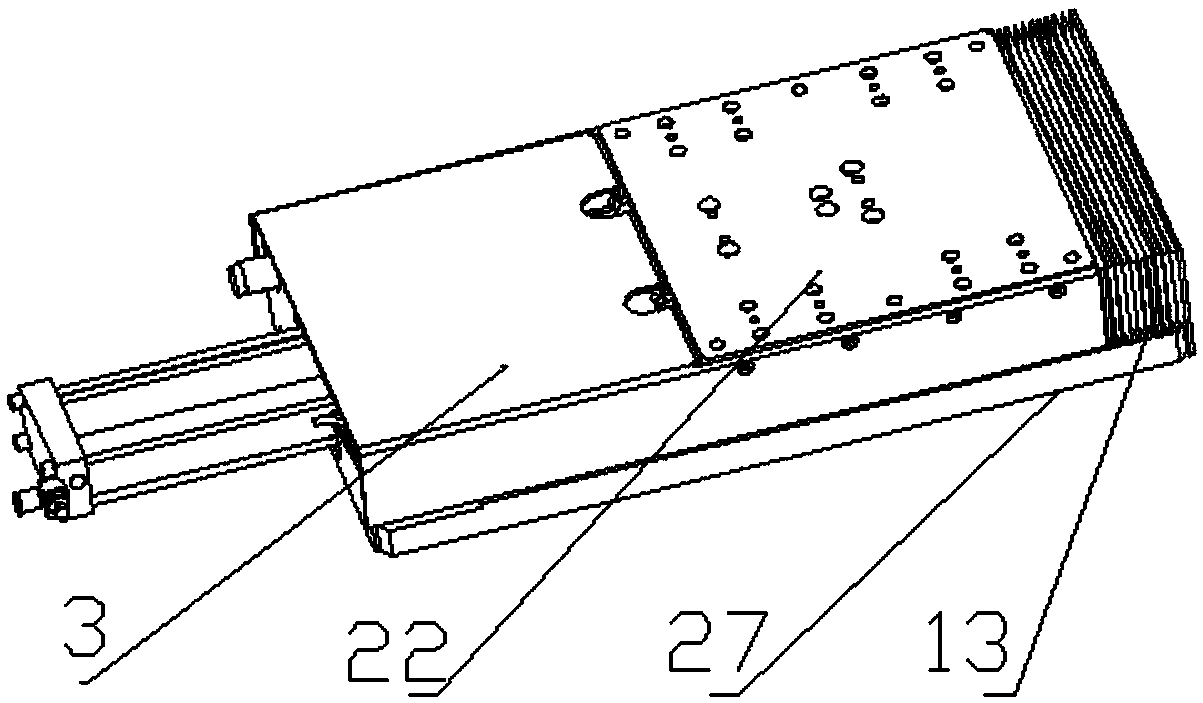

High-speed horizontal reciprocating type extrusion and dehydration machine for fruit and vegetable waste

InactiveCN110848707AFast actionIncrease productionDrying solid materials without heatIncinerator apparatusProcess engineeringScrew conveyor

The invention relates to a high-speed horizontal reciprocating type extrusion and dehydration machine for fruit and vegetable waste. The high-speed horizontal reciprocating type extrusion and dehydration machine comprises a pump station support, a hydraulic power station, a body frame, an extrusion main oil cylinder, an extrusion barrel cavity, an extrusion column, a feeding opening, an extrusionmain drill bit, a first-stage screening barrel, a screening barrel housing, a second-stage screening barrel, a drainage trough, an extrusion auxiliary drill bit, a slag outlet cavity, an extrusion auxiliary oil cylinder, a discharging screw conveyor and a discharging opening. Dehydration reduction can be achieved, the aims of reducing the volume of fruit and vegetable waste and reducing the watercontent of fruit and vegetable waste are achieved, and therefore the problems that when fruit and vegetable waste is incinerated, efficiency is low, the storage capacity is consumed by sanitary landfill, a great amount of percolate is generated, the period of aerobic composting is long, and the occupied area is large are solved.

Owner:深圳龙澄高科技环保股份有限公司

A guide for sheet conveying

ActiveCN106097567BSimple structureSimple structural designCoin/currency accepting devicesArticle feedersEngineeringMechanical engineering

Owner:广州智清电子科技有限公司

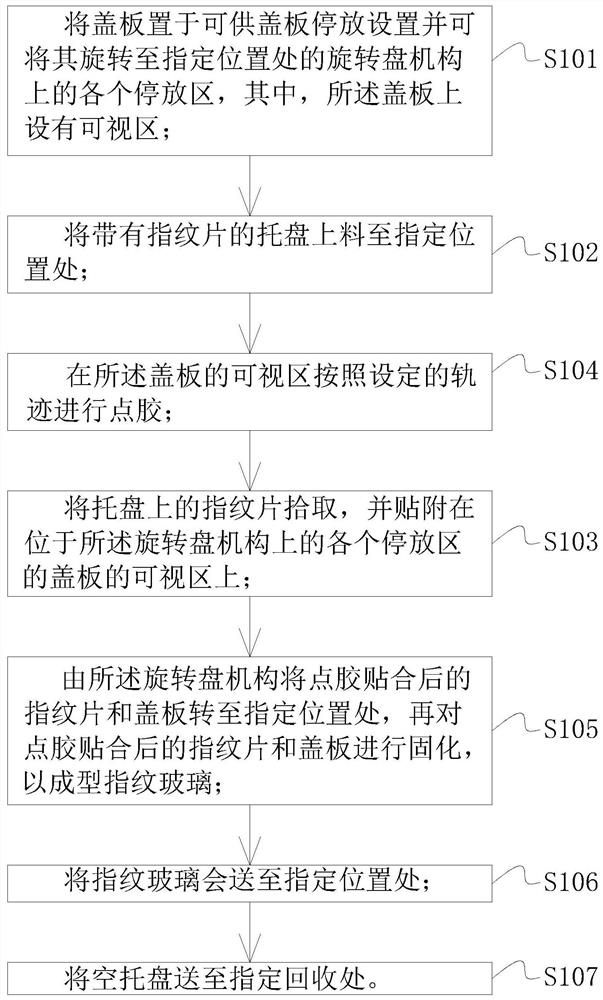

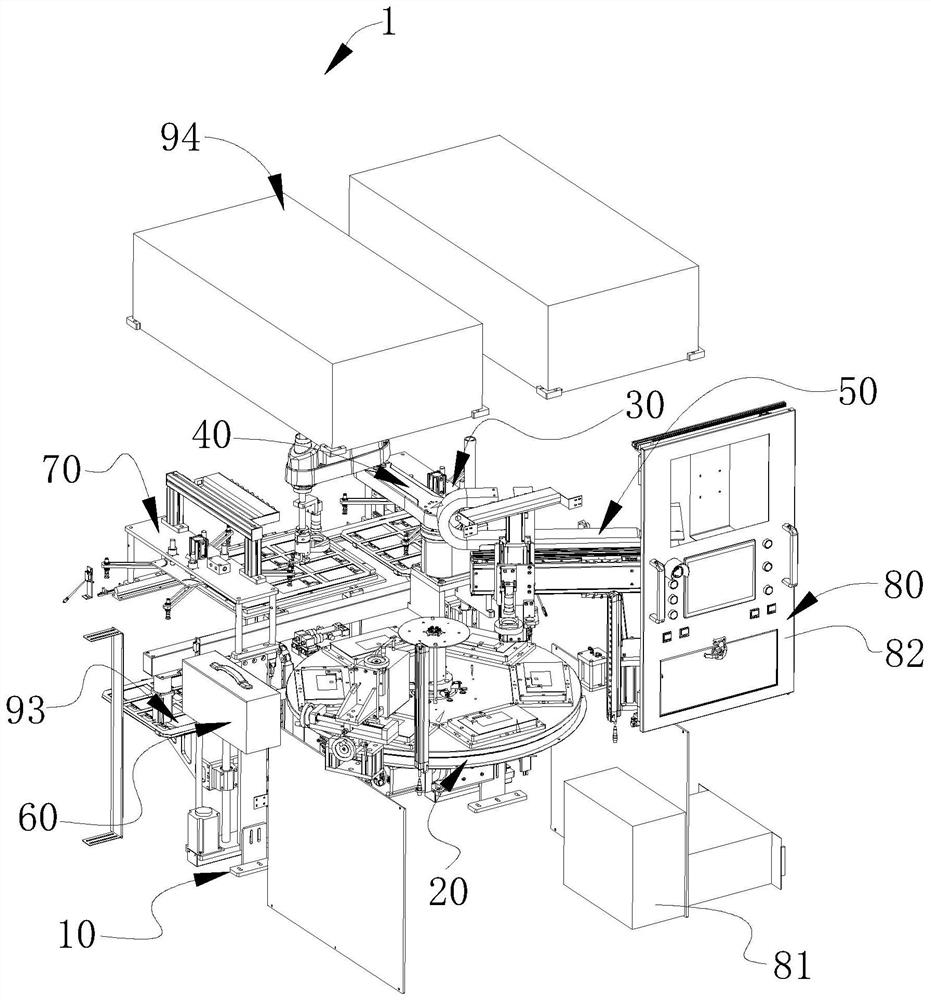

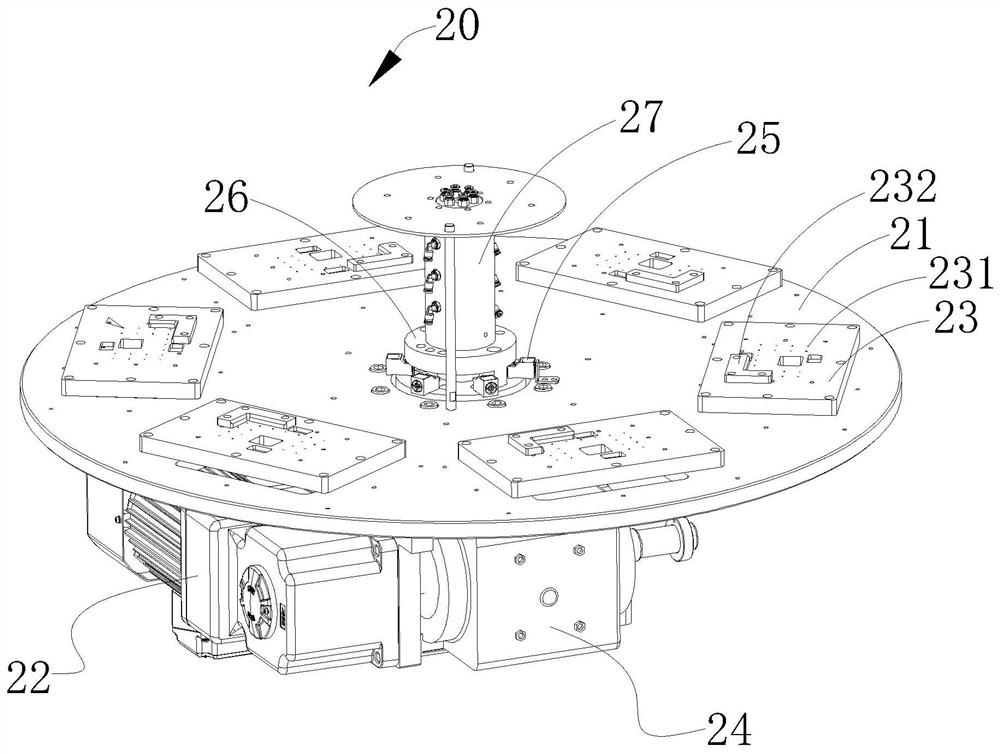

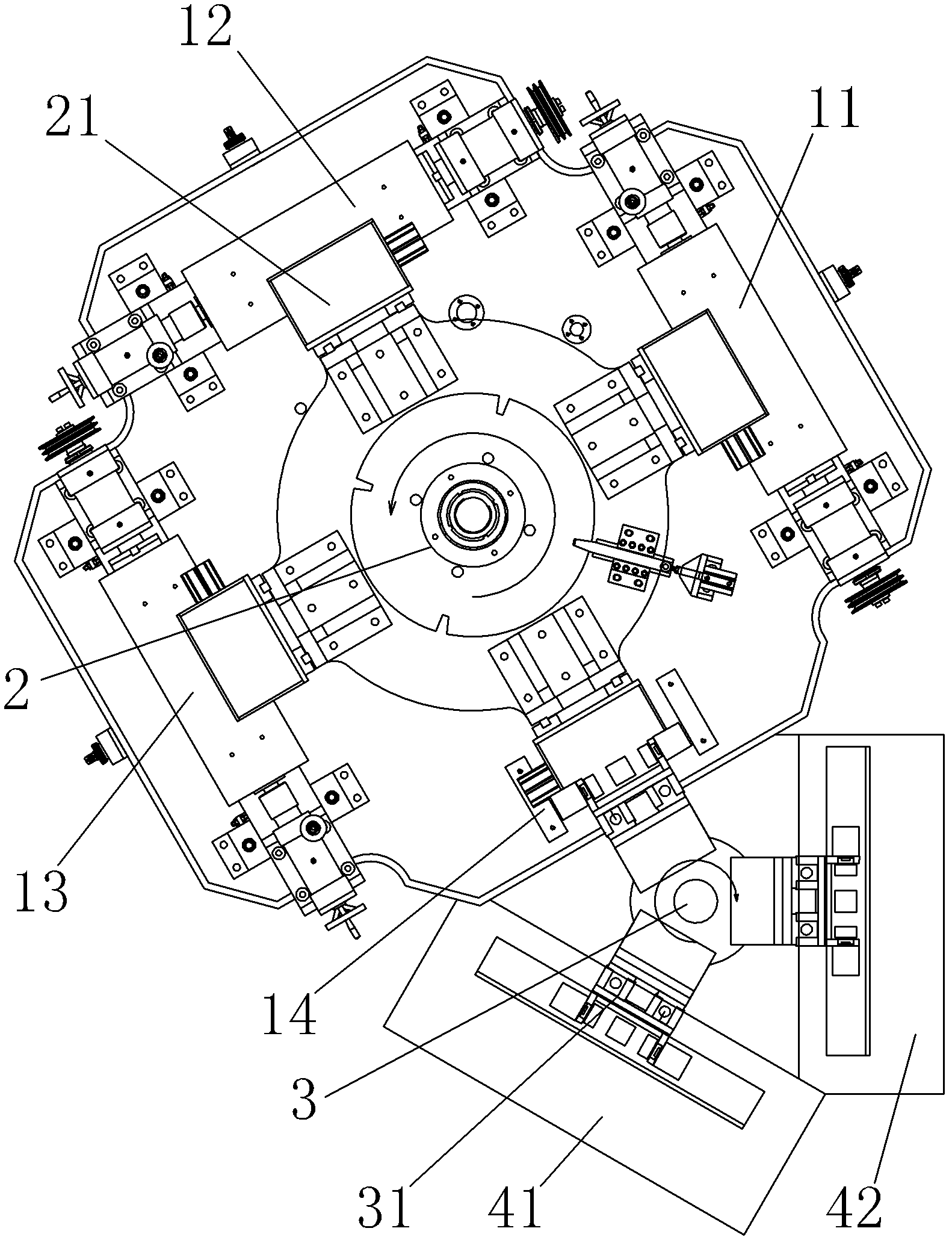

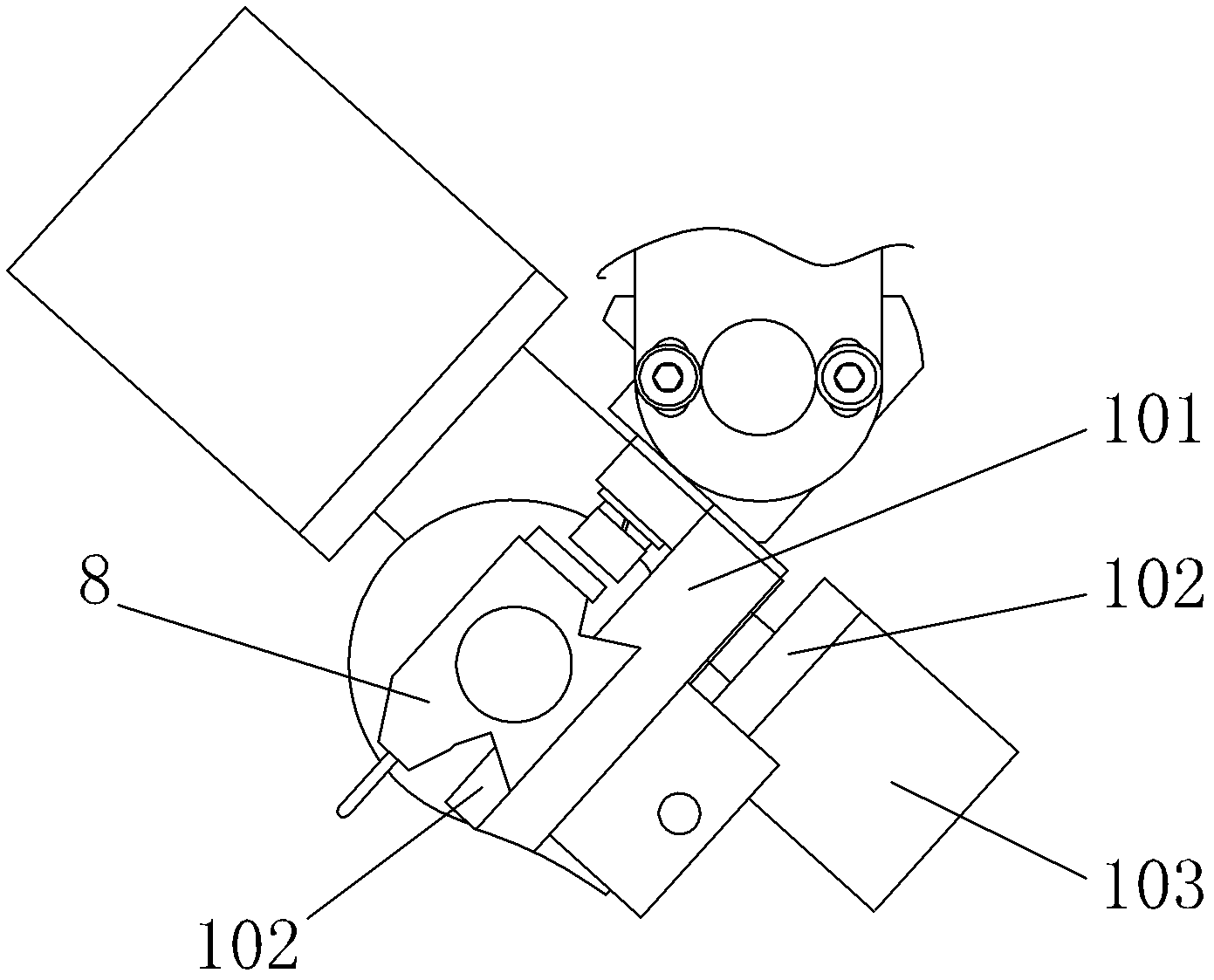

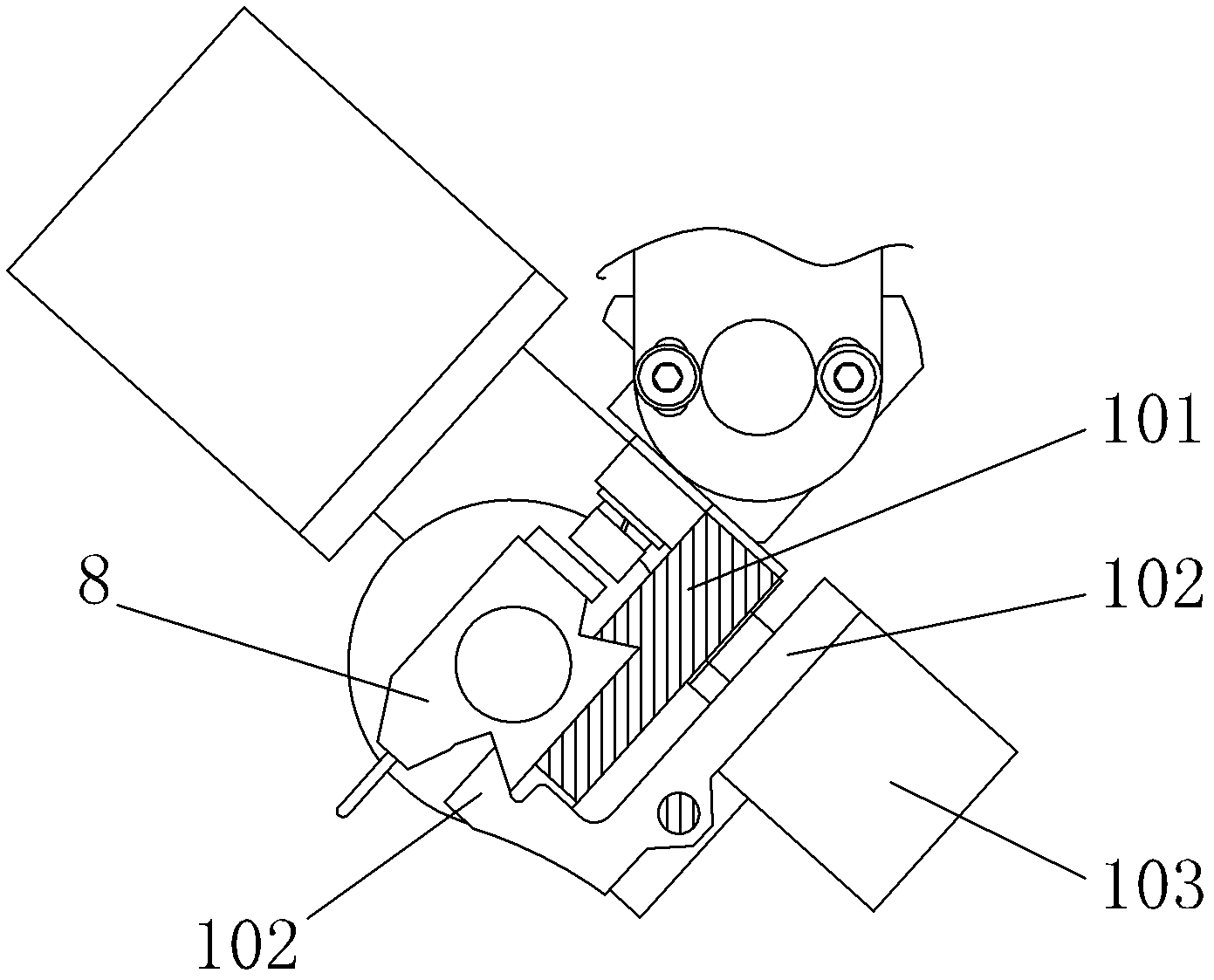

Fingerprint glass automatic bonding method

ActiveCN110390274BClosely connectedShort stayMaterial gluingPretreated surfacesParking areaBonding process

An automatic bonding method for fingerprint glass, including feeding a tray with fingerprint sheets to a designated position; dispensing glue in the visible area of the cover plate according to the set track; picking up the fingerprint sheets on the tray, and attaching them On the visible area of the cover plate in each parking area on the rotating disk mechanism; the rotating disk mechanism will turn the glued fingerprint sheet + cover plate to the designated position, and then the pasted The product is cured to form the fingerprint glass; the fingerprint glass is sent to the designated location; the empty pallet is sent to the designated recycling place. Using the fingerprint glass automatic bonding method of the present application can form a turntable bonding process, which effectively solves the problems of large volume and long relative distance between input and output of the bonding equipment in the prior art due to its linear bonding process , and the movement of each station needs to be individually controlled and executed.

Owner:东莞京川精密机械设备有限公司

Electromagnetic Cooking Appliance and Its Output Power Calculation Method

The invention discloses an electromagnetic cooking appliance as well as a method for calculating the output power of the electromagnetic cooking appliance. The method comprises the following steps: acquiring the rated power of the electromagnetic cooking appliance and acquiring calculation reference power; acquiring the maximal modulation power ratio according to the minimum value of the preset target control power and the rated power, and acquiring the minimal average power according to the calculation reference power and the maximal modulation power ratio; acquiring the current target control power of the electromagnetic cooking appliance and acquiring the modulation power heating time ratio according to the minimal average power and the current target control power; according to the modulation power heating time ratio, the maximal modulation power ratio, the minimal average power, the current target control power and the calculation reference power, acquiring the output power of theelectromagnetic cooking appliance. According to the calculation method, the output power of the electromagnetic cooking appliance can be directly acquired, data lockup is avoided and the program is simple to control.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

A mechanical assembly mechanism

Owner:东莞市钜升智能机械有限公司

Controller for street lamp, advertisement lamp and exterior illumination lamp

InactiveCN1286348CReduce usage costsReduce management costsElectrical apparatusElectric light circuit arrangementElectrical conductorEngineering

The conductor connects the input end, the circuit of signal of the coming current, the microprocessor, the control circuit and the output end. The power is connected to the microprocessor. The controlling program in the microprocessor for switching on / off the street lamps, the advertising lamps and the shooting lamps for outer door scene. The invented equipment is installed on traffic main arteries, shopping centers etc. The 50-70% of the lamps in the equipment can be controlled to turn off and delayed to turn on. Thus, the 30-60% energy can be saved so as to prolong the service time and reduce the management cost.

Owner:耿玉顺

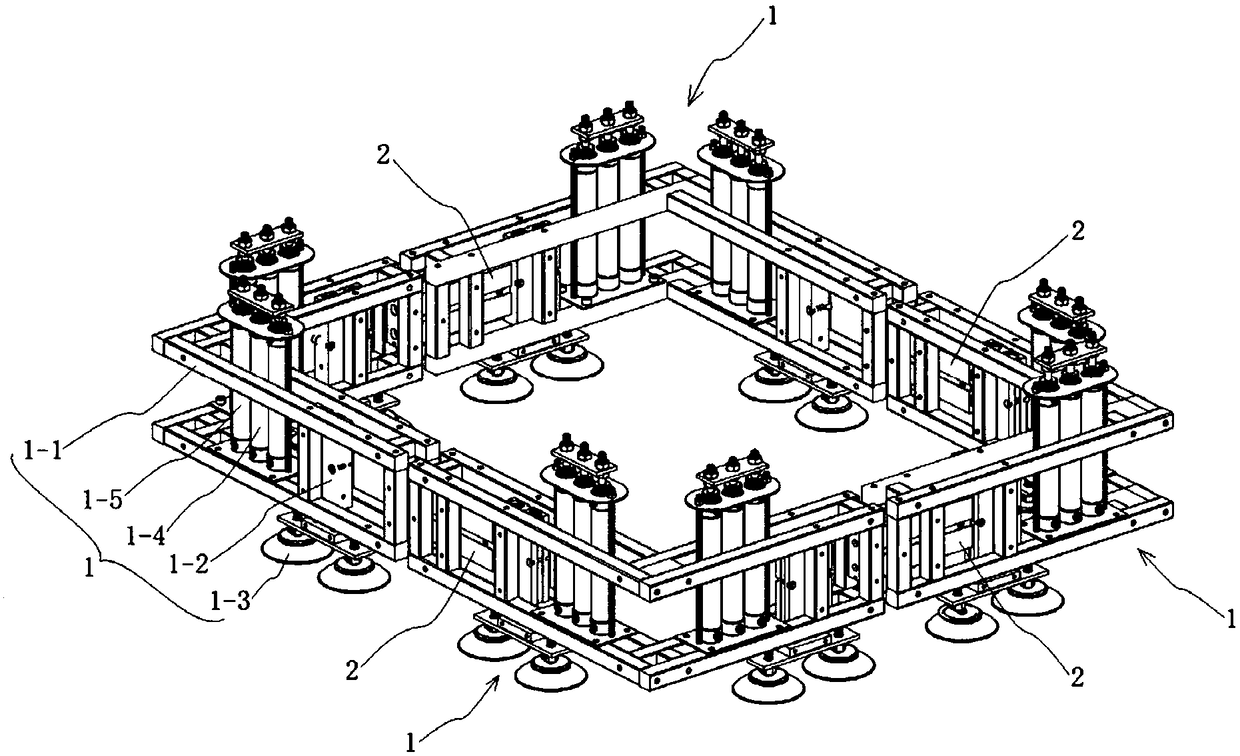

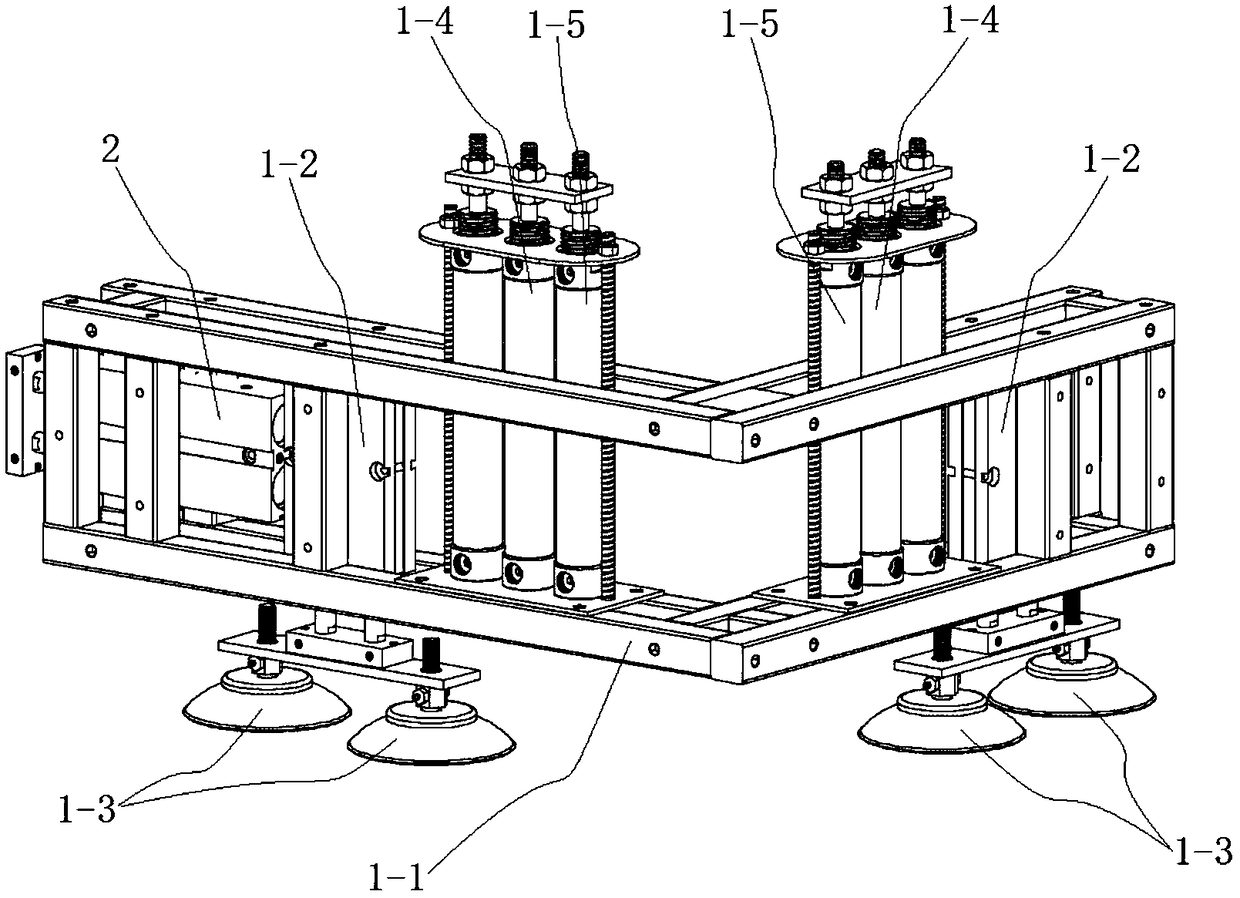

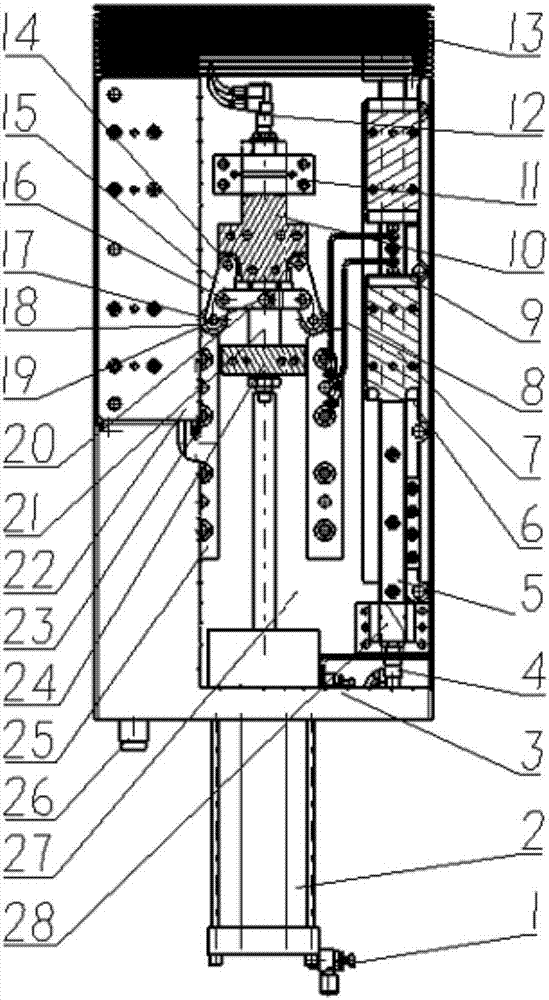

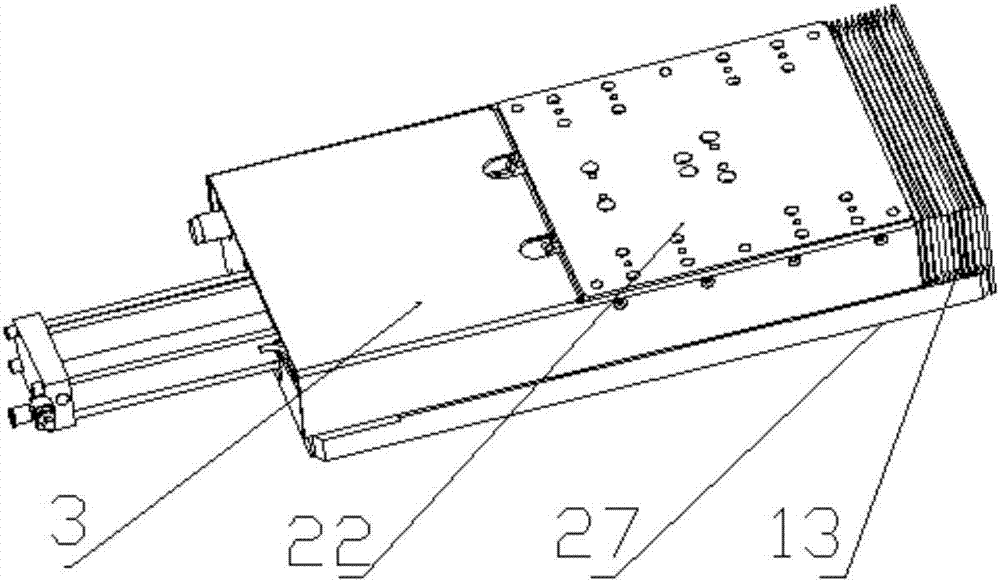

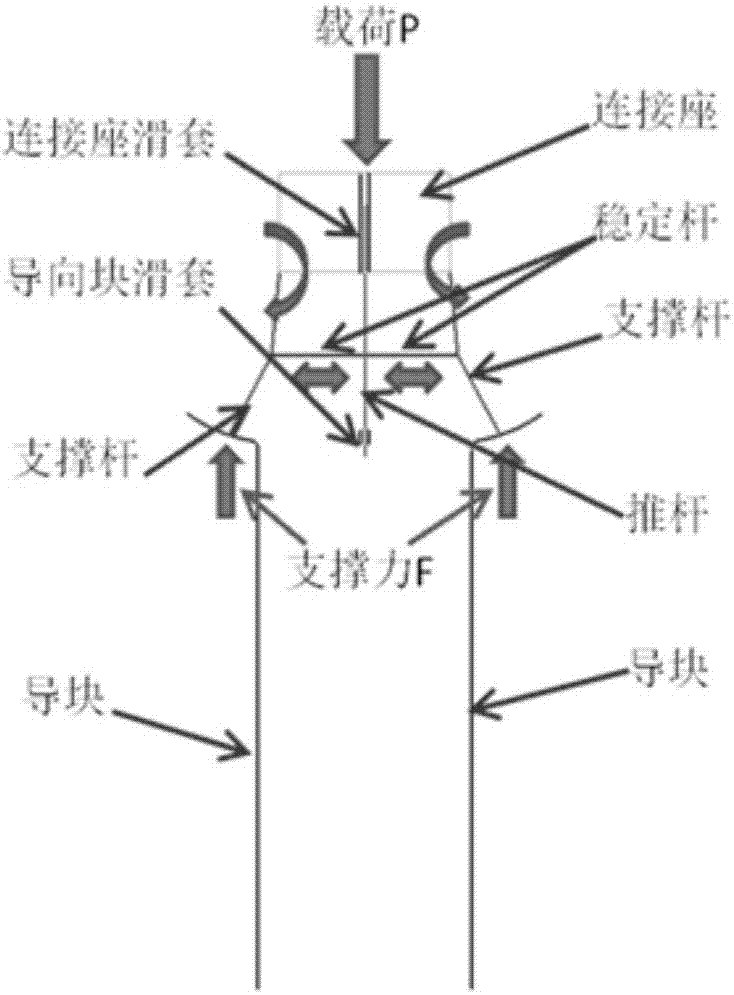

Wall climbing mechanism of glass curtain wall cleaning robot and working method thereof

ActiveCN108577654ACompact structureEasy and flexible operationAutomatic obstacle detectionTravelling automatic controlAir pumpControl theory

The invention discloses a wall climbing mechanism of a glass curtain wall cleaning robot and a working method thereof, and belongs to the technical field of wall climbing robots. The wall climbing mechanism is entirely controlled by a cylinder to realize wall climbing action, a complicated servo motor driving mechanism is not required, and program control is simplified. A walking mechanism is formed by head-to-tail connection of four sets of walking assemblies through four sets of walking cylinders. Through the telescopic movement of two sets of opposite walking cylinders cooperating with theadsorption and loosening action of sucking discs on the walking assemblies, the glass curtain wall cleaning robot moves steadily in both horizontal and vertical directions, and the structure of the walking mechanism is simpler and more compact. The operation is flexible and convenient, and the work efficiency is higher; and moreover, air exhaust cylinders are used by the walking assemblies to produce vacuum negative pressure towards the suction discs. Each air exhaust cylinder needs less air, the requirement for an air pump is low, practical operation and practicability are better, and the sucking discs are connected with the air exhaust cylinders one to one. The air leakage of a suction disc does not affect the whole walking mechanism, and higher safety and reliability are achieved.

Owner:CHANGZHOU INST OF TECH

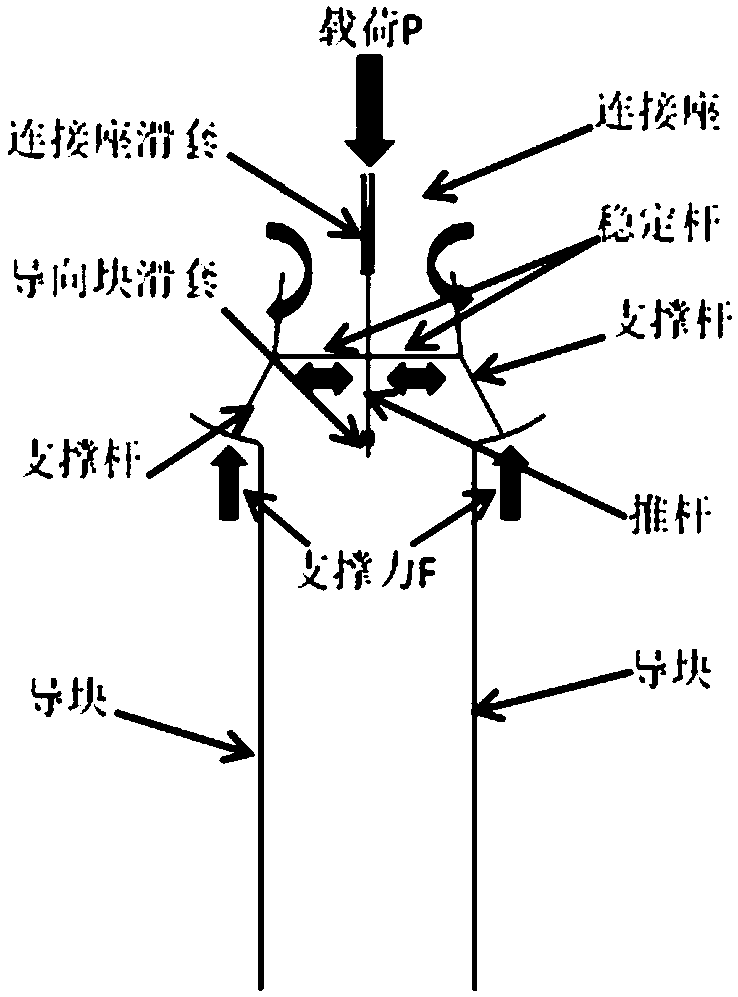

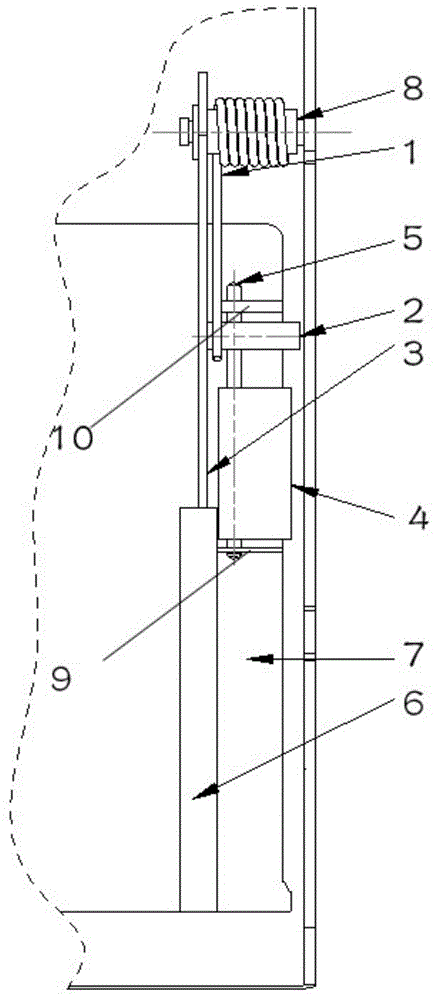

Lifting positioner

ActiveCN107416497AAvoid shockEnsure safe productionControl devices for conveyorsPackagingLinear motionEngineering

The invention discloses a lifting positioner characterized by comprising a buffer self-locking device, a linear motion accuracy control device, a lubricating device, an antiskid device and a signal feedback device. According to the lifting positioner disclosed by the invention, the in-position buffering and self-locking functions are achieved through the mechanical structure characteristics. Under normal working conditions, the in-position buffering is finished automatically to avoid impact, so that the safety production is ensured; at the same time, the structure is optimized and simplified, and the manufacturing cost and fault points of equipment are reduced; and the maintenance cost of the equipment is reduced, and the program control is also simplified.

Owner:刘云梦

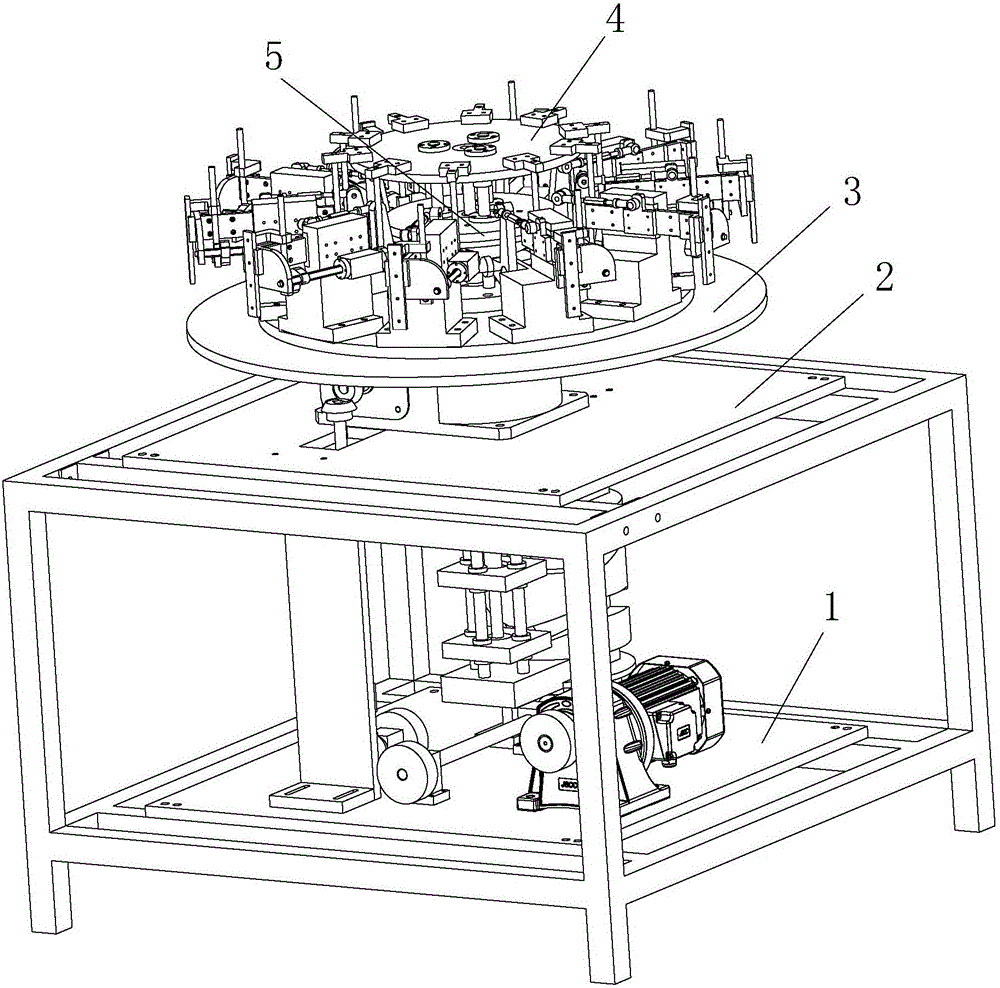

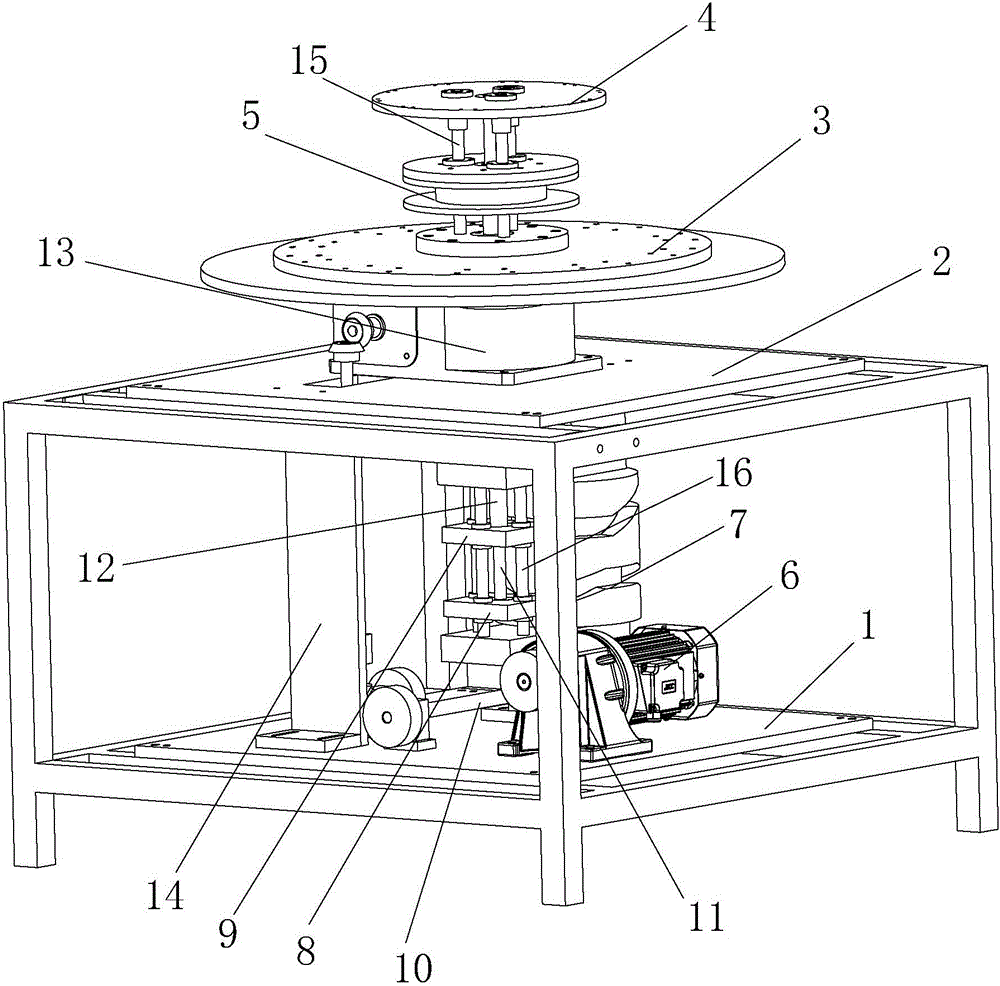

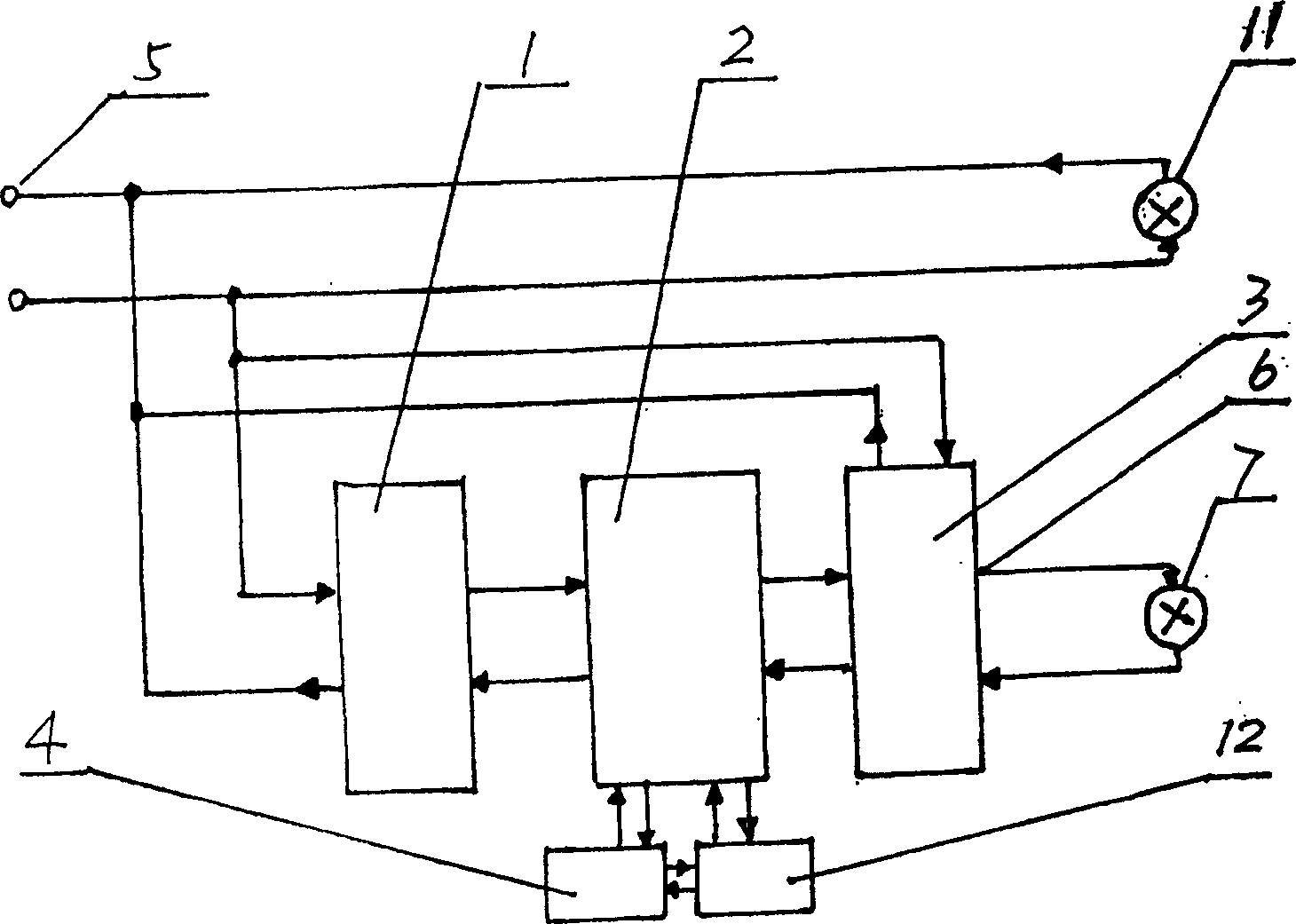

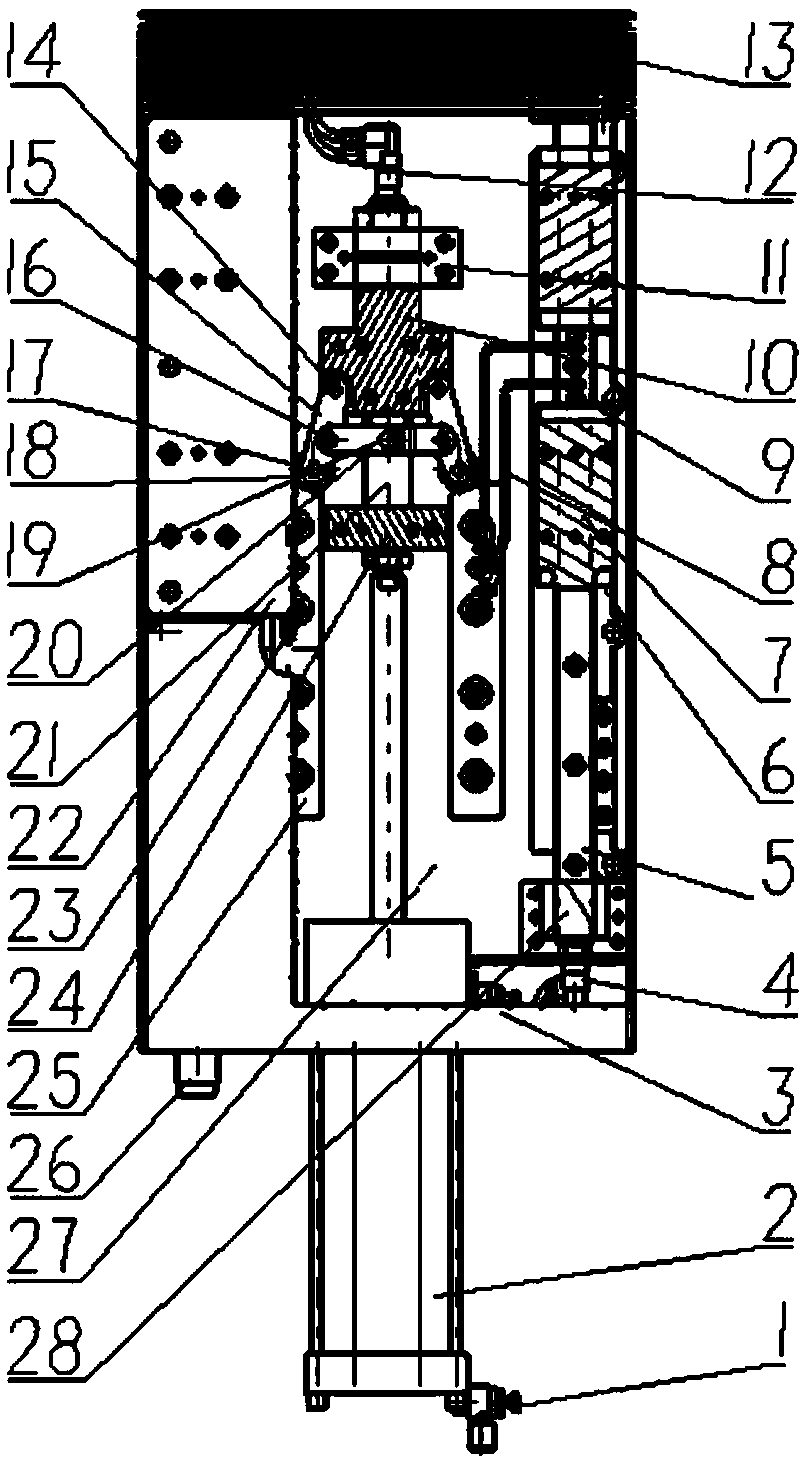

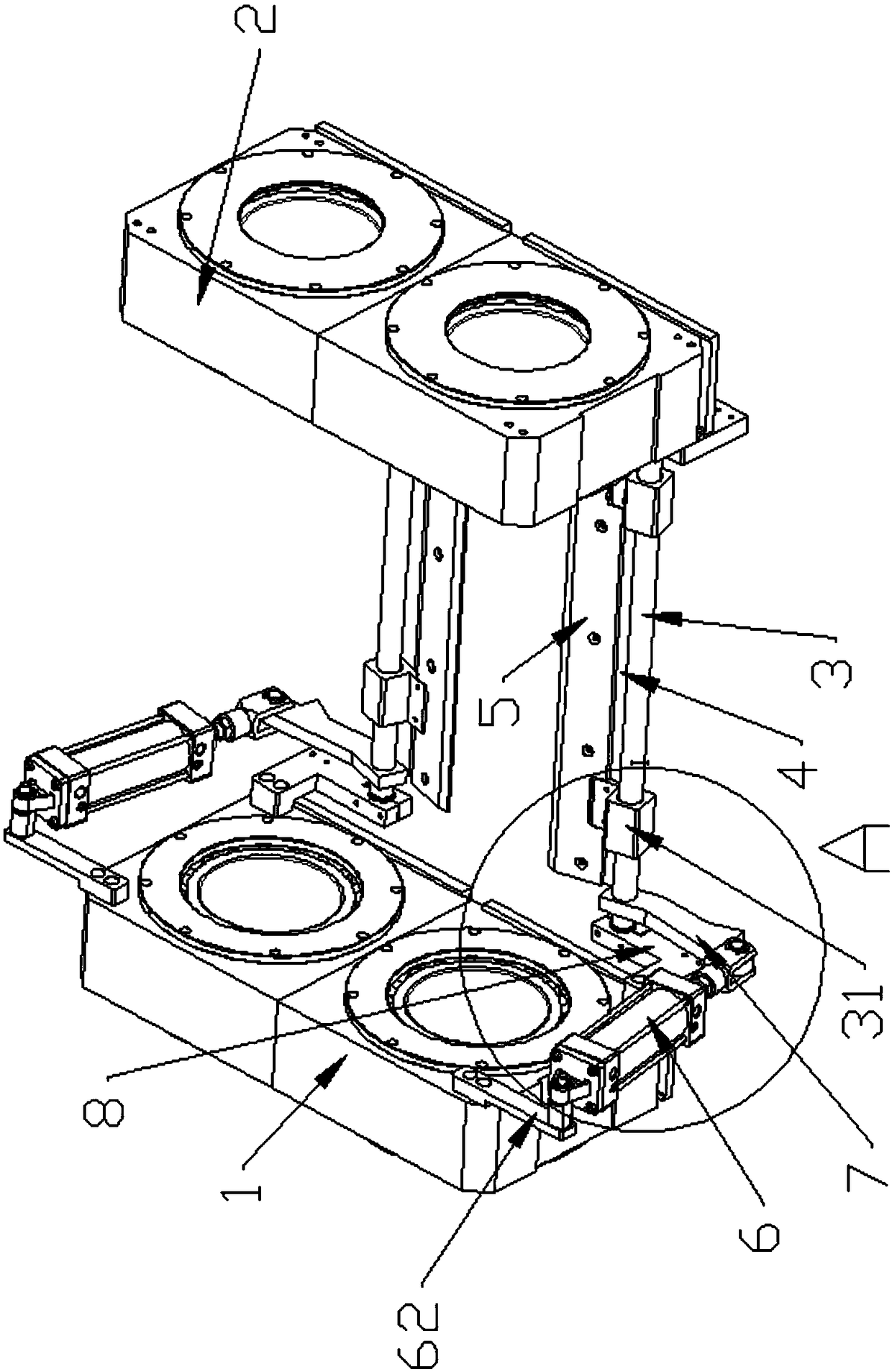

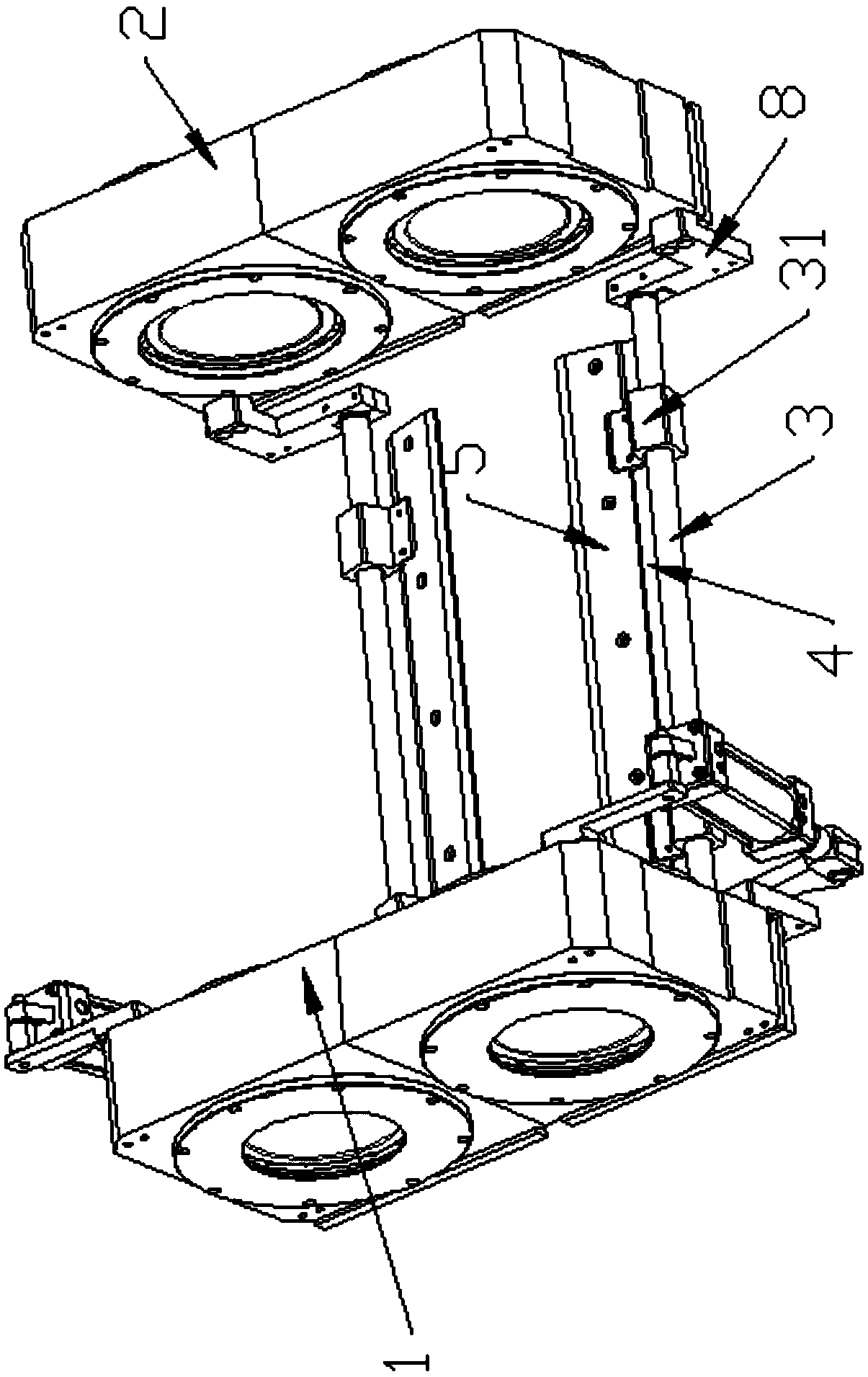

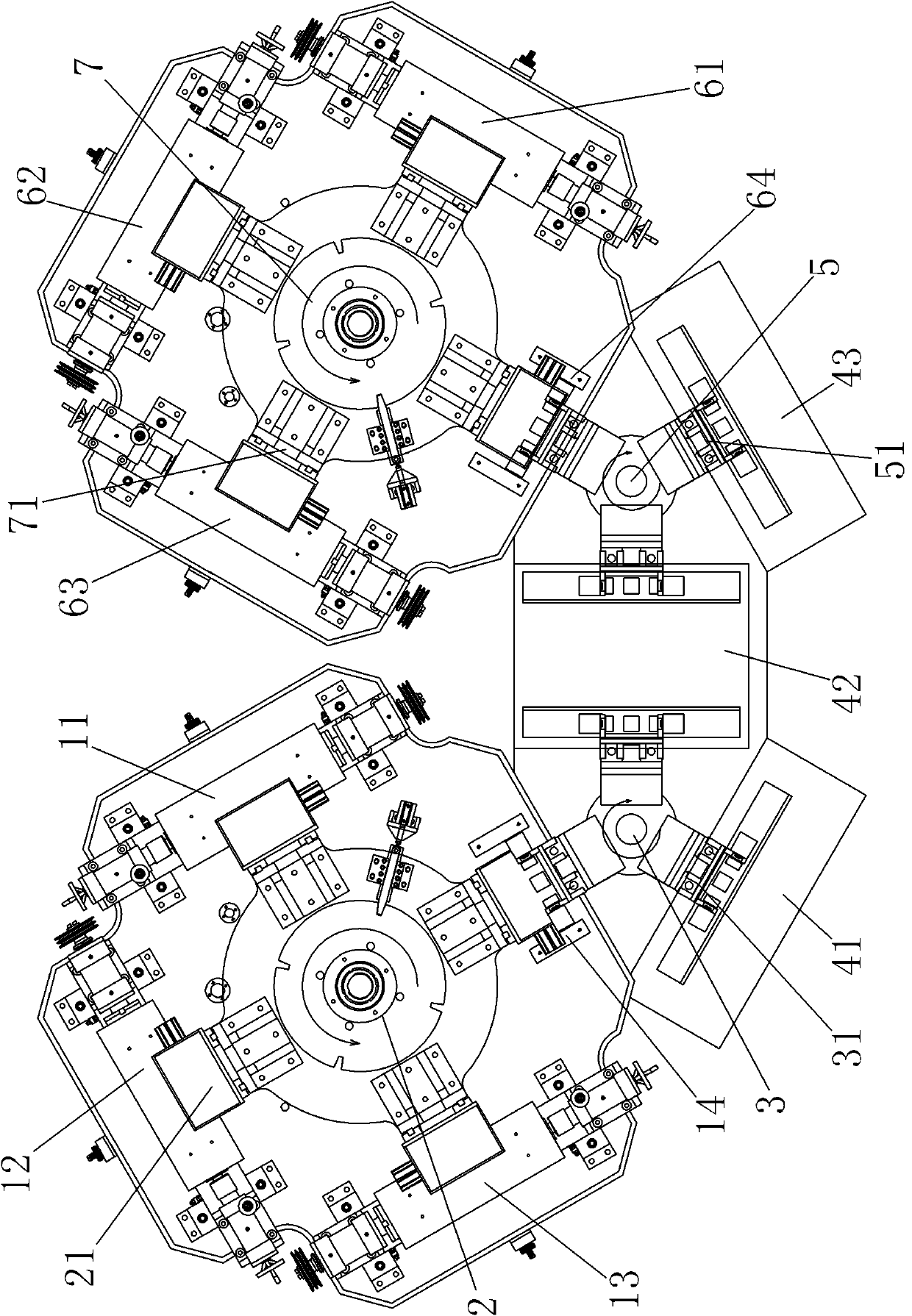

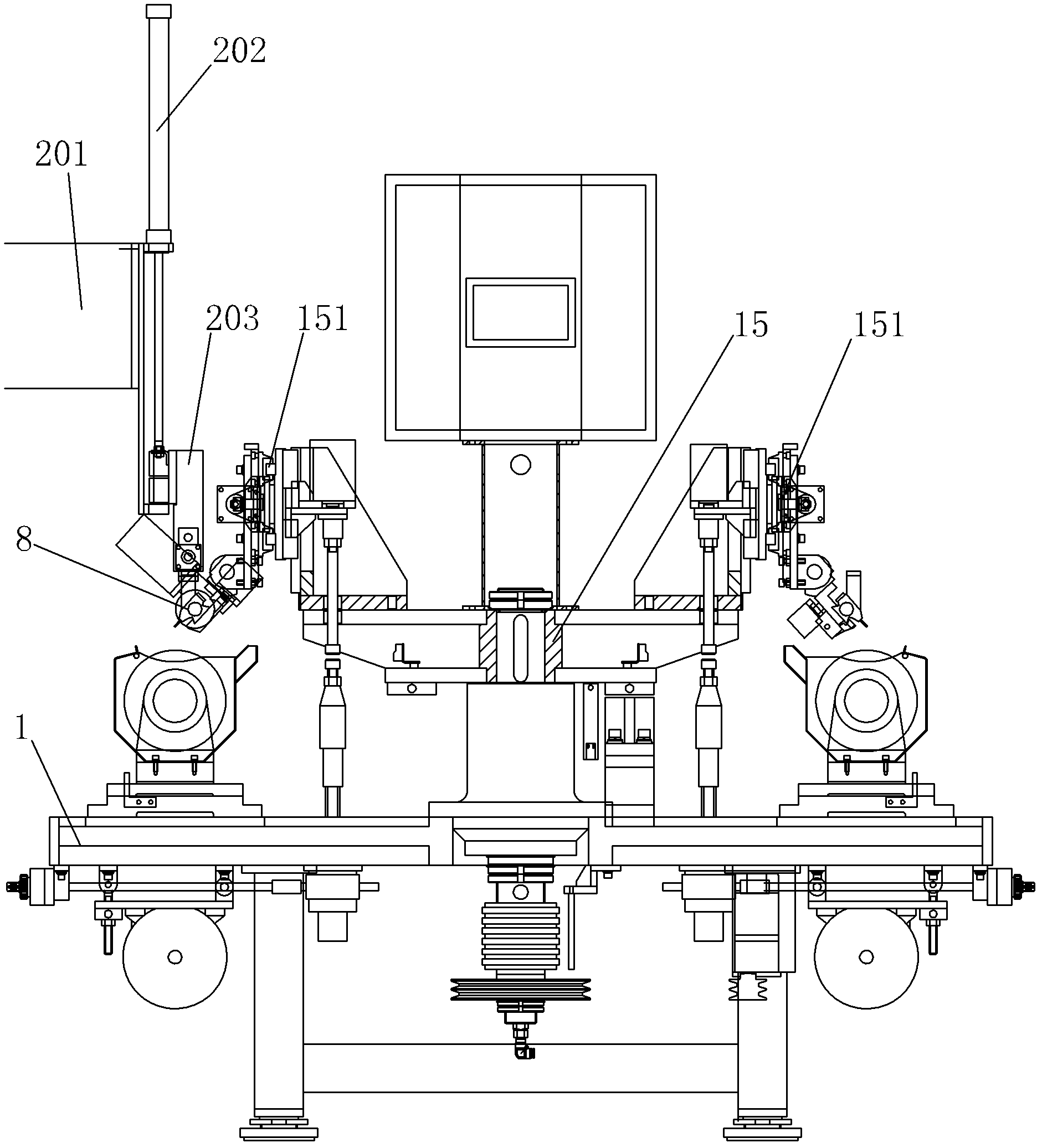

Automatic grinding and polishing system for crystal blank, and auxiliary machinery of automatic grinding and polishing system

InactiveCN102240943BSimplify the complexity of the actionGuarantee the quality of grinding and polishingEdge grinding machinesEngineeringTransfer mechanism

The present invention relates to an automatic grinding and polishing system for crystal blanks, comprising: a first rotating frame, wherein a grinding station and a polishing station are provided surrounding the first rotating frame, and the first rotating frame can be rotated and positioned and is provided with at least two drive heads; a material loading station; a material unloading station; and at least one transfer mechanism capable of picking up and laying down a clamp and capable of transferring the clamp between the loading station, the unloading station, and the drive heads on the first rotating frame; wherein a grinding mechanism is provided on the grinding station and a polishing mechanism is provided on the polishing station. Further disclosed is an auxiliary mechanism used by the system. This technical solution can not only realize completely automatic grinding and polishing on a hemispherical bevel of crystal blanks, ensuring the quality of the grinding and polishing, but can also make full use of the advantages of existing types of machine, simplifying the complexities of mechanism actions, while production and maintenance are easy.

Owner:虞雅仙

a lift shifter

ActiveCN107416497BAvoid shockEnsure safe productionControl devices for conveyorsPackagingLinear motionSelf locking

Owner:刘云梦

Accurate liquid extracting and metering device and method

ActiveCN101655423BEfficient screeningSimple program controlWithdrawing sample devicesCapacity measurement calibrationEngineeringLiquid extract

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

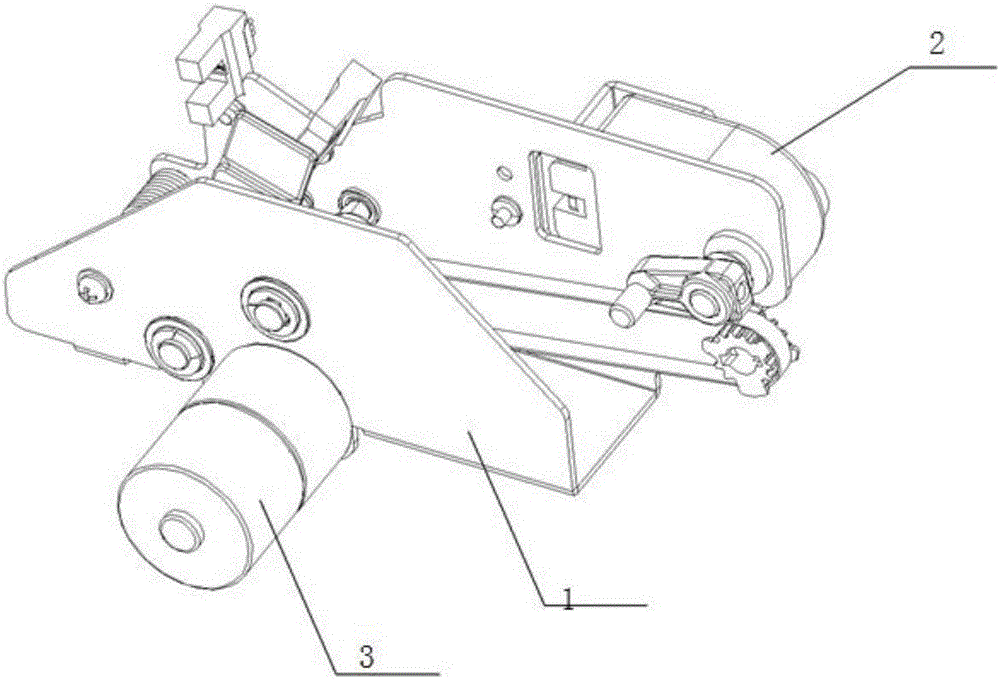

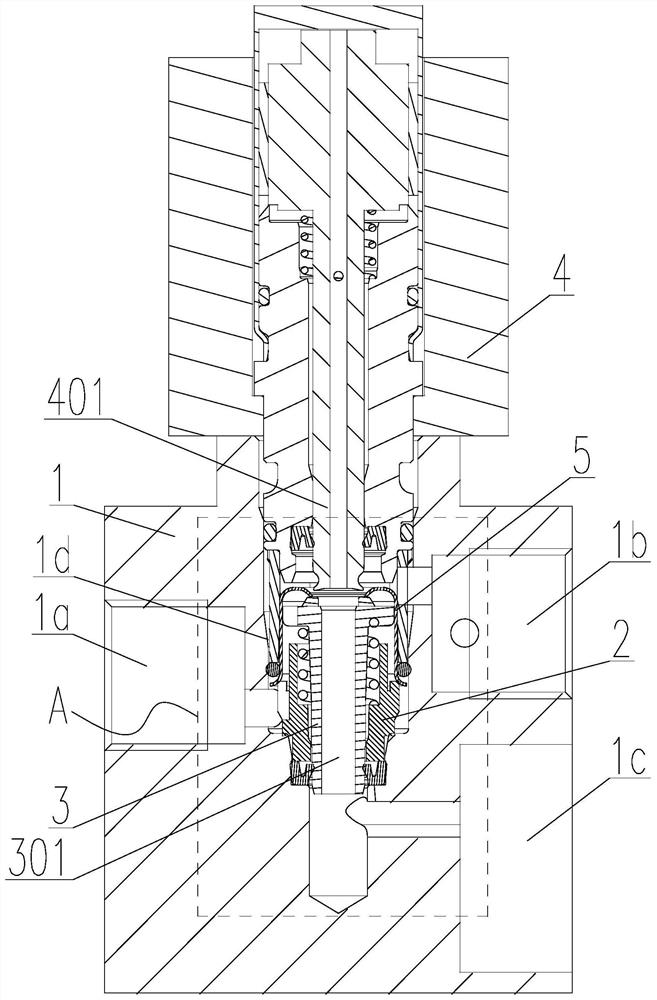

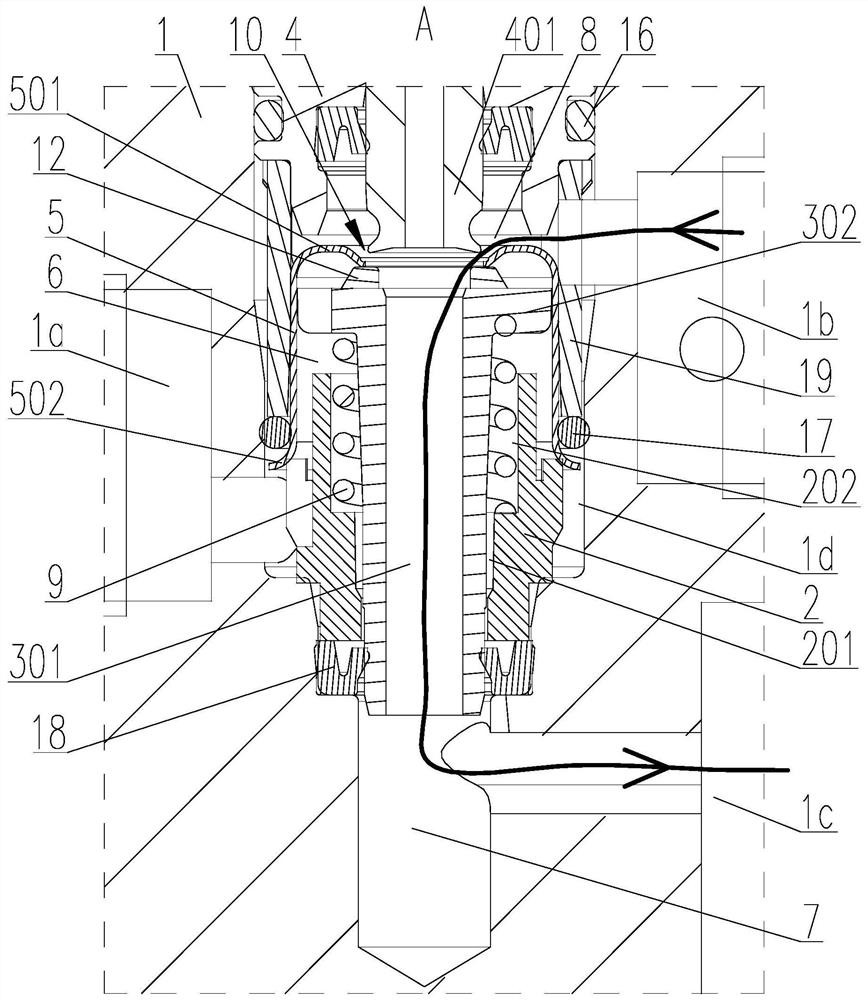

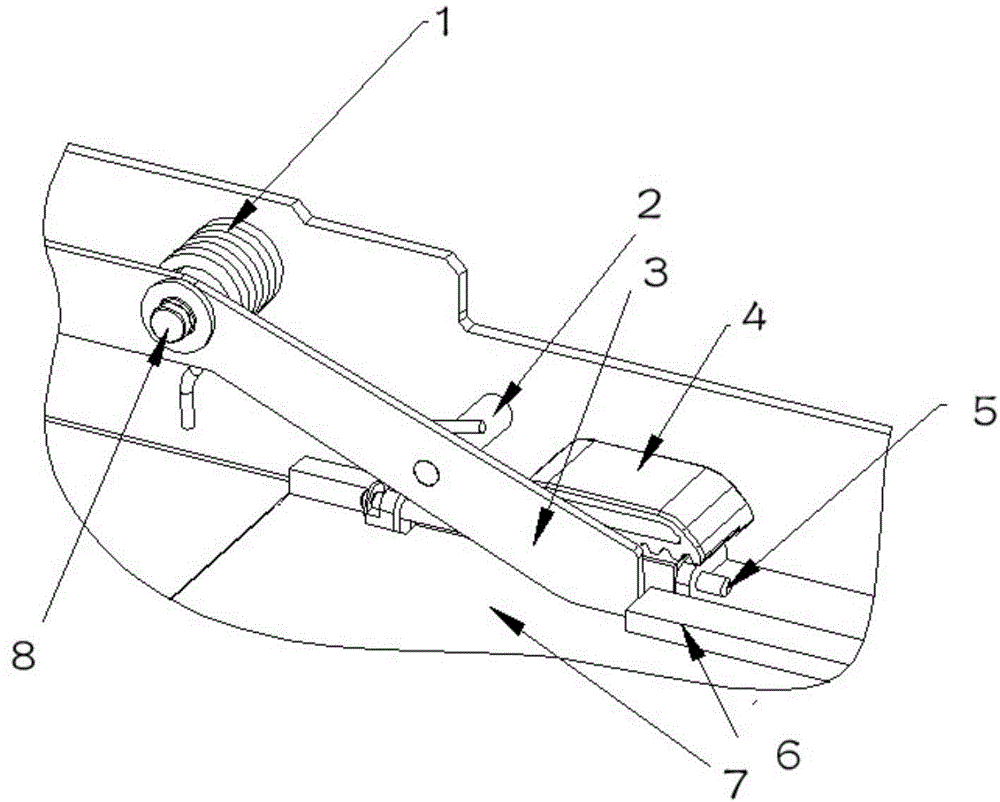

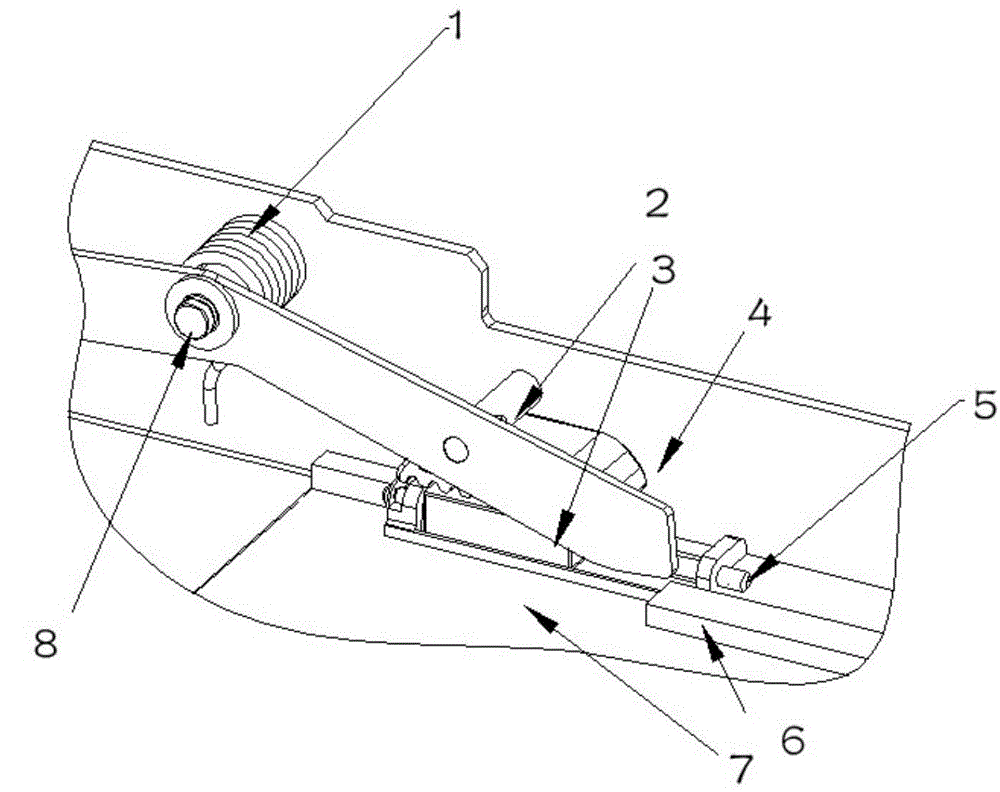

Delayed gate unlocking device for financial service terminal

ActiveCN105442953ALow costSimple program controlPower-operated mechanismTime locksTorsion springSelf locking

The invention relates to a delayed gate unlocking device for a financial service terminal. The delayed gate unlocking device comprises a gate with a braking clamping block, a braking block slide rail arranged on one side of the gate braking clamping block, a braking block and a self-locking arm, wherein the braking block is arranged on the braking block slide rail and moves along the braking block slide rail, and the self-locking arm is arranged above the braking block slide rail and can be reset through a torsion spring to rotate. The gate is provided with an upper driving block and a lower driving block, the upper driving block and the lower driving block are arranged below the braking block slide rail, and the braking block moves to touch the upper driving block or the lower driving block so as to enable the gate to move up and down. A convex lug is arranged on one side of the self-locking arm, and the two ends of the upper surface of the braking block are provided with circular beads. According to the delayed gate unlocking device, the gate is locked and unlocked and opened and closed through movement of the braking block, a power device is shared, and cost is reduced; locking and unlocking of the gate are linked with opening and closing of the gate, additional control through programs is not needed, and program control is simplified; the delayed gate unlocking device is simple in structure and easy to mount and maintain.

Owner:CASHWAY FINTECH CO LTD

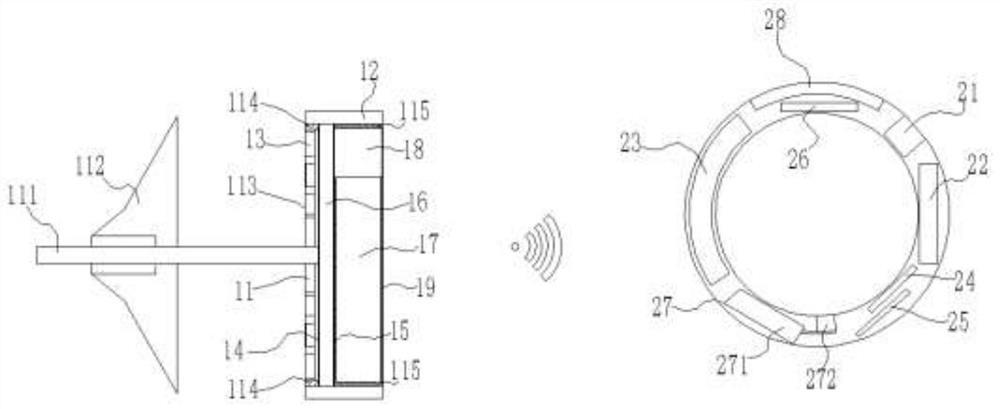

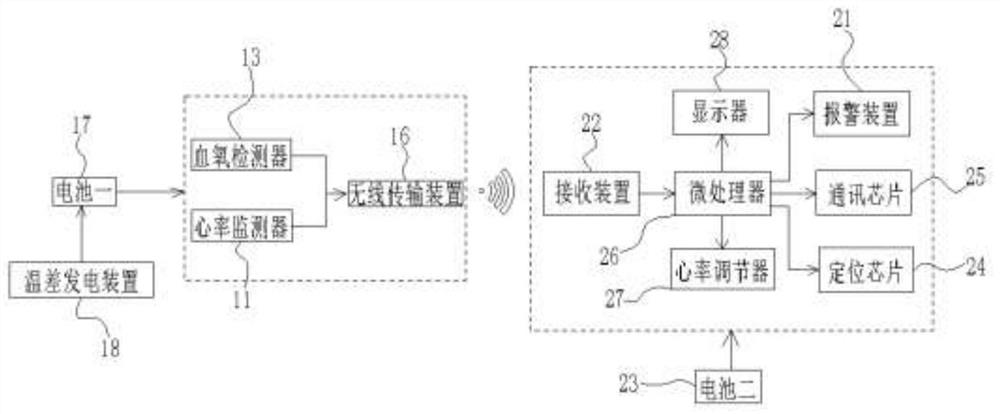

Wearable heart rate monitoring and alarming device

InactiveCN111671406AReduce volumeSimple program controlSensorsMeasuring/recording heart/pulse rateMedical emergencyHeart rate monitoring

The invention discloses a wearable heart rate monitoring and alarming device. The device comprises earrings and a bracelet, wherein the earrings are used to monitor heart rate and blood oxygen condition, the bracelet is used for alarms and active communication, an emergency communicator can be set by connecting the bracelet with a mobile phone. Compared with traditional bracelets for monitoring the heart rate, the earrings are used as a monitoring device and can be kept close to skin at all times, the monitoring accuracy and accuracy are high, the device also has a blood oxygen monitoring function to monitor a patient with double standards, the monitoring result is more accurate, the earrings are equipped with a power generation device, no additional charging is required, so that the device is more convenient, can perform 24-h uninterrupted monitoring on the patient, and has the function of preventing sudden death of the patient at night.

Owner:GUIZHOU PROVINCIAL PEOPLES HOSPITAL

AGV trackless trolley drive wheel automatic correction device

ActiveCN105235775BRun fastRealize automatic centeringNon-deflectable wheel steeringVehiclesDrive wheelProgrammable logic controller

The invention discloses an automatic correction device for driving wheels of an AGV trackless trolley, which comprises a trolley and a magnetic strip. Sensor, left driving wheel, left driver, two universal wheels and two road wheels, the programmable logic controller PLC is housed in the described on-board controller, it is characterized in that: also comprise driving gear, driven gear, rotating shaft I , the rotating shaft II and the angle correction potentiometer, the rotating shaft I and the rotating shaft II are mounted on the car body, and the rotating shaft I is installed in the middle position between the left driving wheel and the right driving wheel, and the driving gear is fixedly mounted on the driving inside the assembly housing. The invention has a novel structure, can realize automatic centering of the navigation sensor, automatic alignment and alignment between the driving wheel and the magnetic strip, simple program control, stable operation, safety and reliability, and long service life.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

Pull rod mechanism

The invention discloses a pull rod mechanism which comprises a penicillin bottle pull rod and two groups of turnover modules. The two groups of turnover modules are respectively arranged at two ends of the penicillin bottle pull rod, each group of turnover modules comprises a turnover body, a rotary shaft and a downward-turning bumping block, each end of the penicillin pull rod is connected to the turnover body through the rotary shaft, and the downward-turning bumping block is connected with the rotary shaft and drives the rotary shaft to rotate so as to enable the penicillin bottle pull rod to be downward turned after being bumped. The pull rod mechanism further comprises upward-turning bumping rods and upward-turning bumping blocks, wherein the upward-turning bumping blocks are arranged on the turnover bodies and connected with the rotary shafts, the upward-turning bumping rods are fixed to moving paths of the upward-turning bumping blocks, and the rotary shafts are driven to rotate so as to enable the penicillin bottle to be upwards turned when the upward-turning bumping blocks bump against the upward-turning bumping rods. The pull rod mechanism is simple in actions, programs are easily controlled, additional turnover motors are not needed, and cost is saved.

Owner:上海翡诺医药设备有限公司

Structure for cleaning bottom of drum for rubber processing

The invention provides a structure for cleaning the bottom of a drum for rubber processing, and belongs to the field of rubber plasticizing equipment, the structure comprises a driving shaft, a glue scraping trowel, a cylinder, a left supporting plate and a right supporting plate, wherein the left supporting plate and the right supporting plate are arranged in parallel, the driving shaft is vertically arranged between the left supporting plate and the right supporting plate and is rotatably connected with the left supporting plate and the right supporting plate; the glue scraping trowel is fixedly arranged on the driving shaft through two fixing seats; one end of the cylinder, away from an output shaft, is hinged with the left supporting plate through a bracket; the output shaft end of thecylinder is hinged with one end of a driving rod; the other end of the driving rod is fixedly connected with the driving shaft, the output shaft of the cylinder moves up and down and drives the driving shaft to rotate through the driving rod, the glue scraping trowel comprises a positioning frame and a blade, the positioning frame is fixedly connected with the fixing seats, the blade is fixedly arranged at the upper end of the positioning frame, and a chamfer is arranged at one end of the blade, away from the driving shaft. The device can automatically achieve continuous glue scraping, and has simple control and good glue scraping effect.

Owner:TIANJIN RUILING TECH DEV CO LTD

Crystal blank automatic grinding and polishing system, grinding and polishing machine and auxiliary machine thereof

InactiveCN102248460BSimplify the complexity of the actionGuarantee the quality of grinding and polishingEdge grinding machinesPolishing machinesEngineeringTransfer mechanism

Owner:虞雅仙

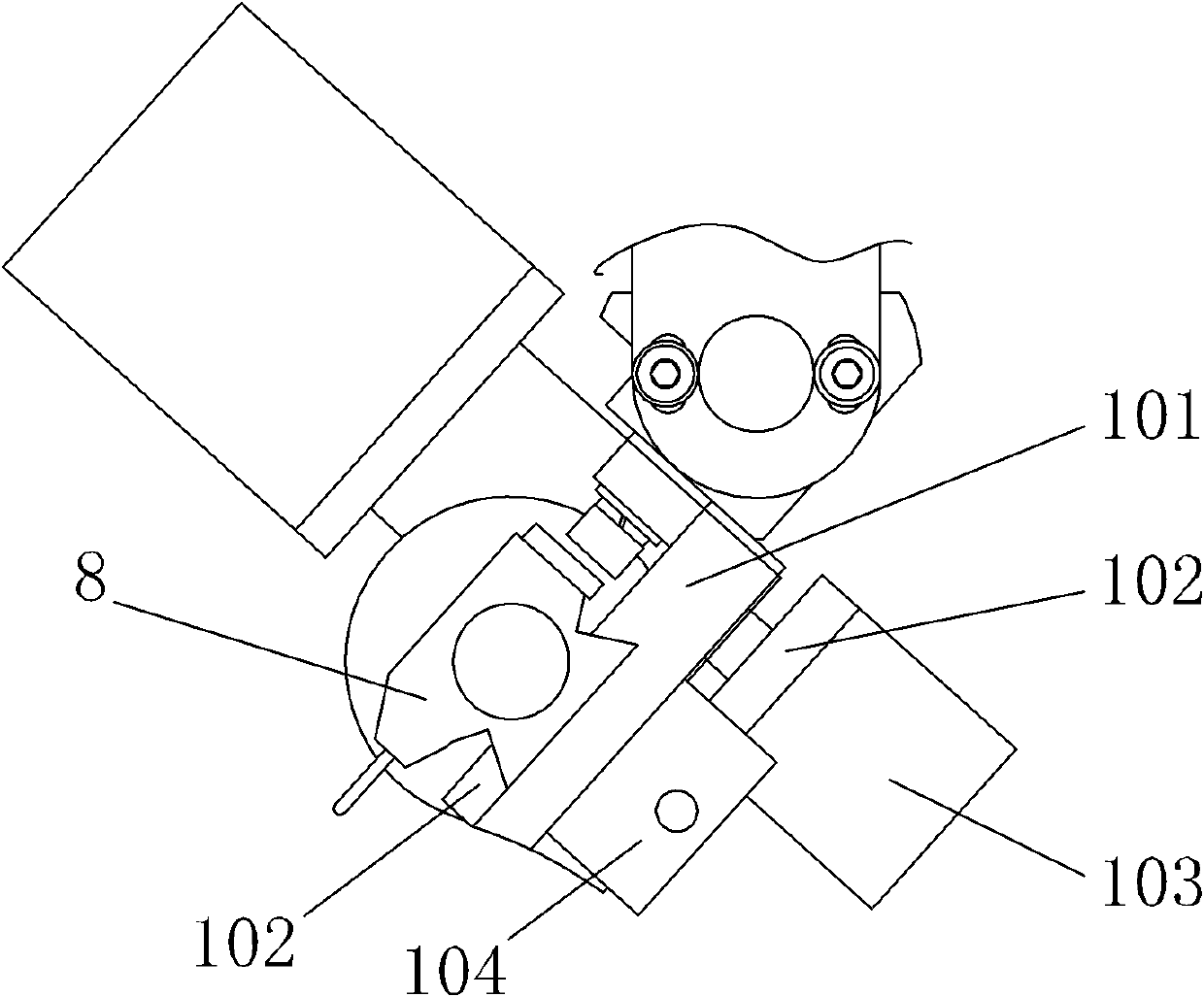

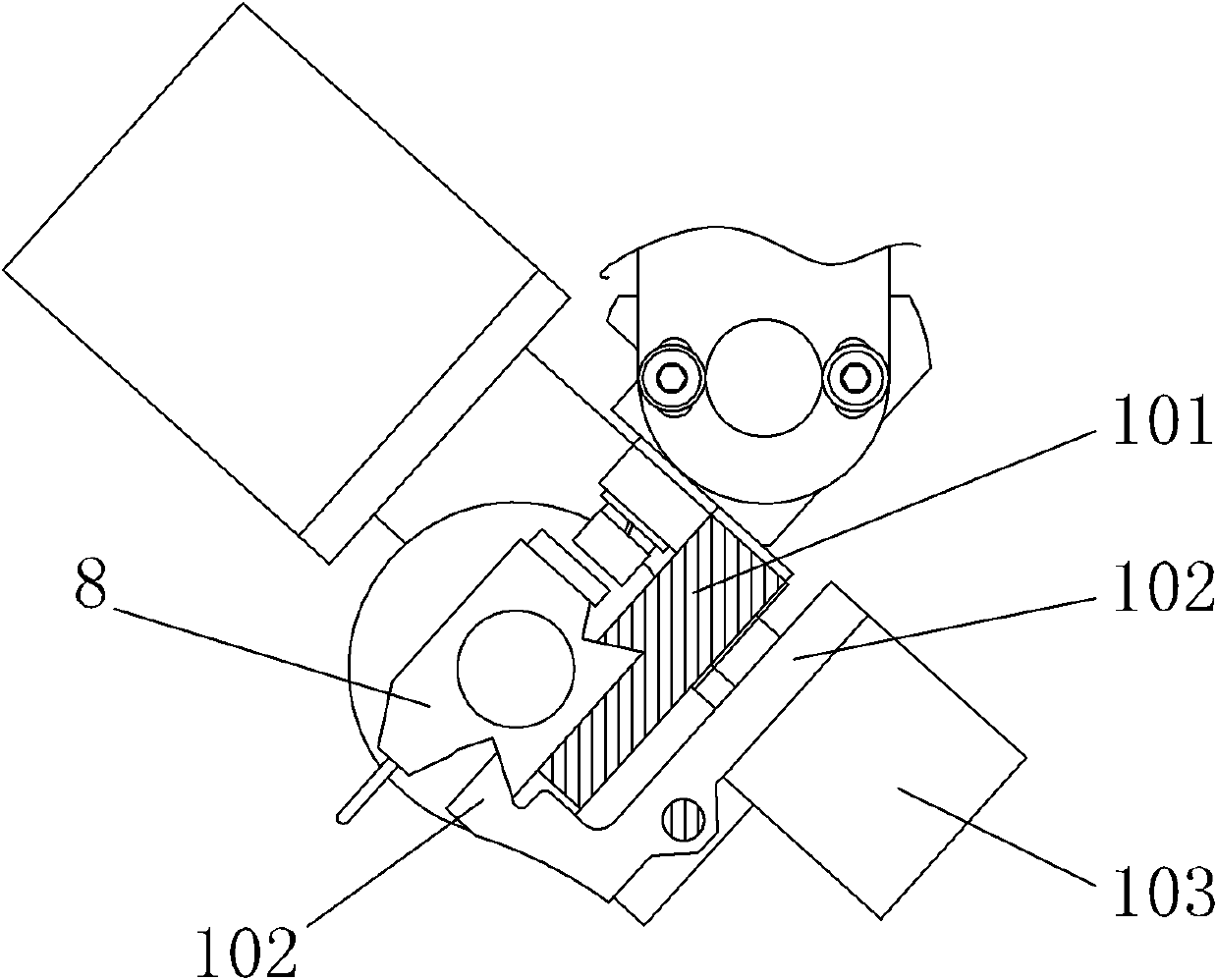

Crystal blank automatic polishing system

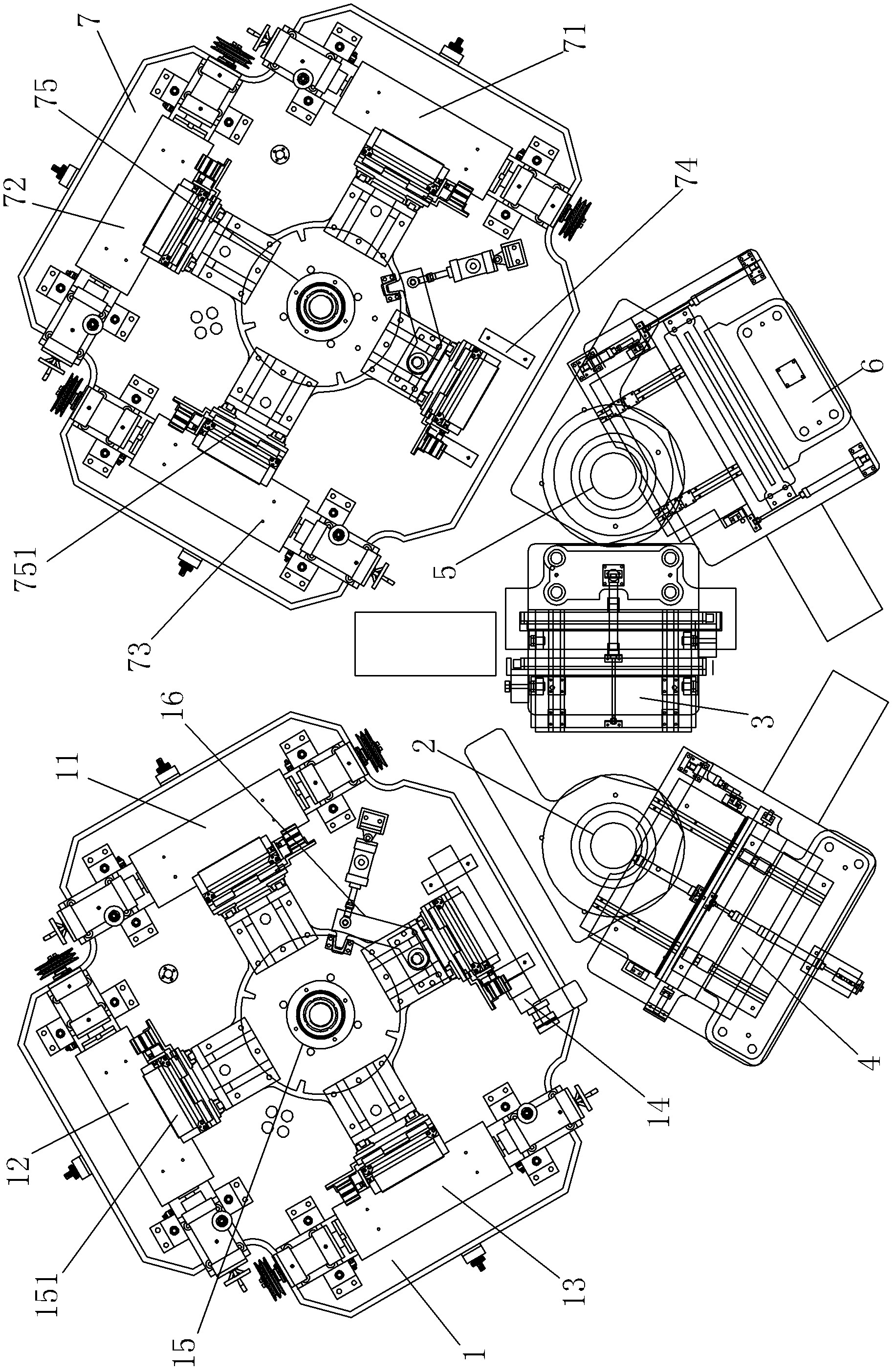

ActiveCN102430967BEnsure processing consistencyGuaranteed manufacturing accuracyEdge grinding machinesGrinding feedersTransfer mechanismMachine models

A system for automatically grinding and polishing a crystal blank comprises: a first rotary frame (15) provided with a head (151), an upper hemisphere grinding station (11) and a polishing station (12, 13); a second rotary frame (75) provided with a head, a lower hemisphere grinding station (71) and a polishing station (72, 73); a loading station (4); a butting station (3); an unloading station (6); a first transfer mechanism (2) capable of picking up and putting down a fixture (8) and transferring the fixture (8) among the loading station (4), the butting station (3) and the head (151) of the first rotary frame (15); and a second transfer mechanism (5) capable of picking up and putting down the fixture (8) and transferring the fixture (8) among the butting station (3), the unloading station (6) and head (751) of the second rotary frame (75). Also provided is a full automatic grinding and polishing system with the same principle and used for processing an inclined plane of a hemisphere of a crystal blank. The invention not only can realize full automatic grinding and polishing of the crystal blank and ensure the grinding and polishing quality, but also can fully utilize the advantages of the existing machine model, simplify the complex mechanism action, and be easy to manufacture and maintain.

Owner:虞雅仙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com