a lift shifter

A technology of positioner and limit block, which is applied in the directions of transportation and packaging, packaging, conveyor objects, etc., can solve the problems of complex structure, complicated program control and high maintenance cost of the lifting positioner, so as to reduce equipment failure points, The program control is simplified and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

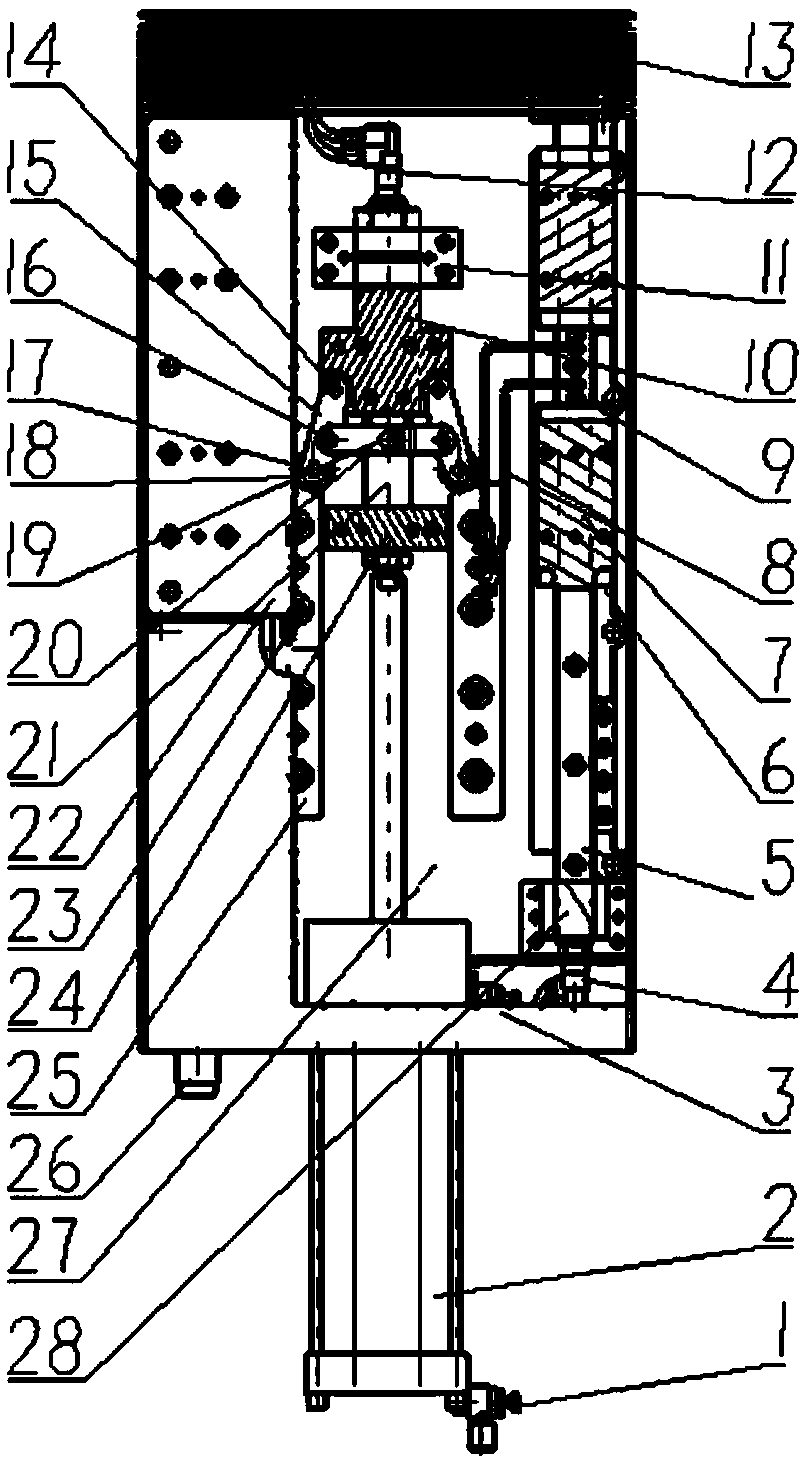

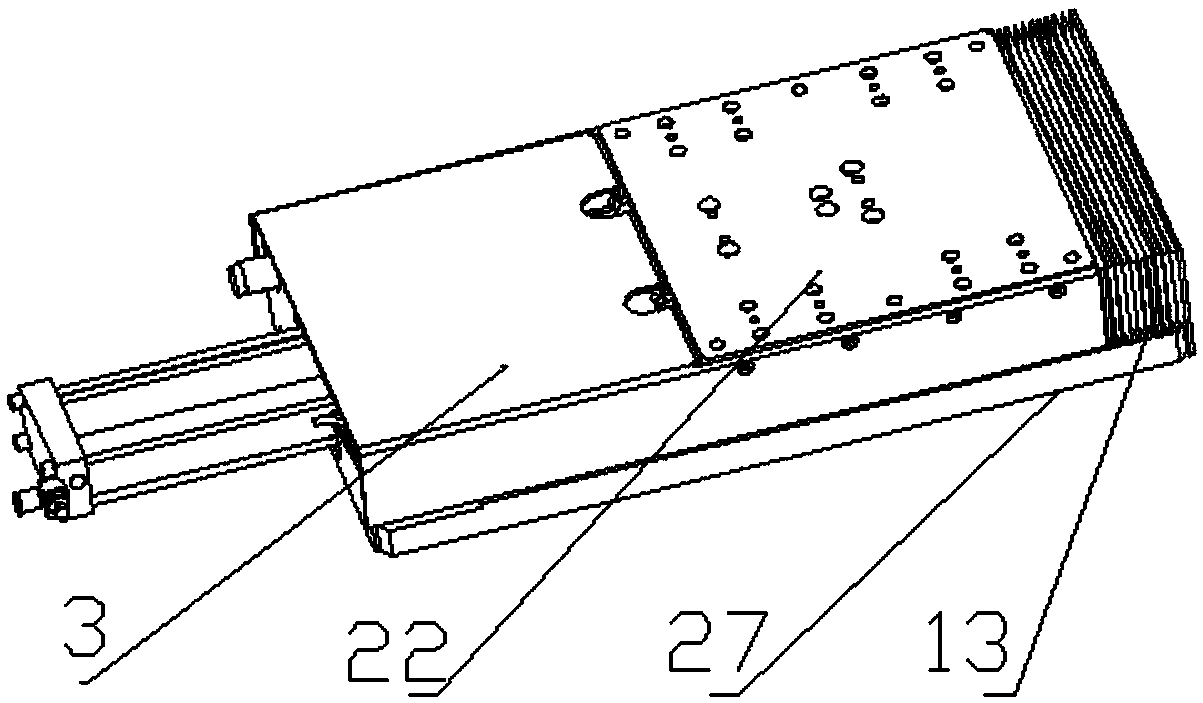

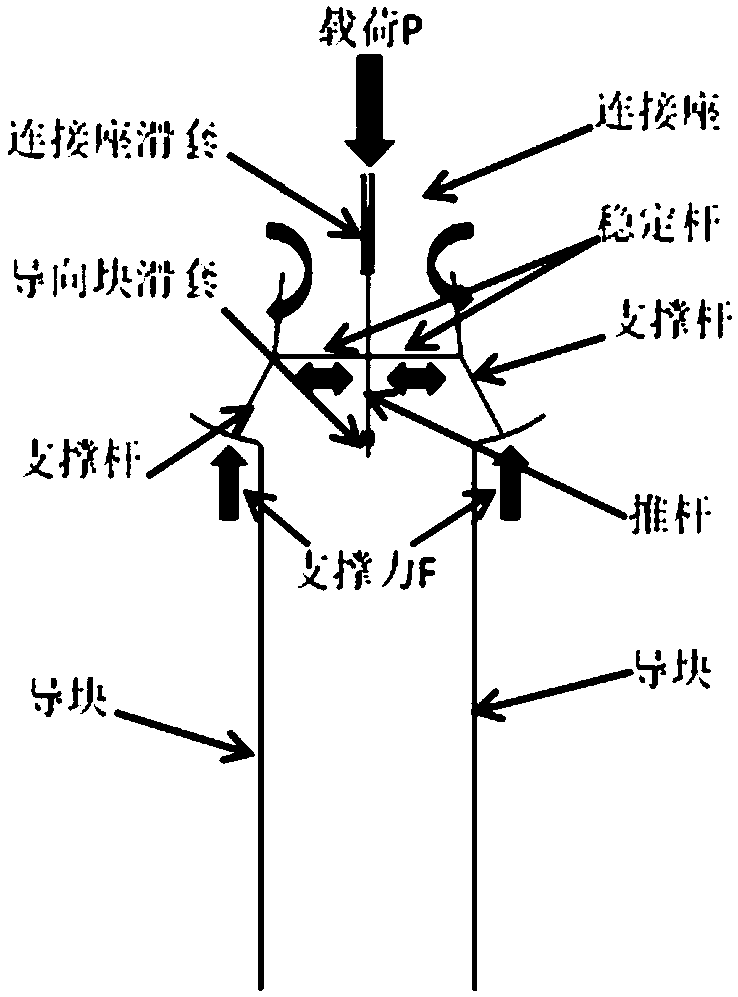

[0034] When the piston rod of the displacement cylinder 2 stretched out, the push rod 21 pushed one end of the stabilizing rod to move upward, and the other end of the stabilizing rod 20 pushed the supporting rod 15 to rotate clockwise around the hinge axis of the supporting rod 15 and the connecting seat 10. Driven by 15, the guide wheel 18 is supported on the guide surface of the guide block 25, the cylinder rod continues to move upward, and the push rod 21, the stabilizer rod 20 and the support rod 15 form a relatively fixed state and move upward together, thereby pushing the connecting seat 10 to drive the installation. Plate 22 moves upwards. When the guide wheel 18 reaches the buffer surface of the guide block 25, the support rod 15 rotates clockwise around the hinge shaft of the support rod 15 and the connecting seat 10 to the working position, the mounting plate 22 stops moving upward, and the active force of the load passes through the support rod 15 directly. It acts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com