High-speed horizontal reciprocating type extrusion and dehydration machine for fruit and vegetable waste

A technology for squeezing dehydrators and fruit and vegetable wastes, which is applied to combustion methods, lighting and heating equipment, drying and other directions, can solve the problems of reducing the water content of fruit and vegetable wastes, low incineration efficiency of fruit and vegetable wastes, and reducing the volume of fruit and vegetable wastes. Compact, fast action, high throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

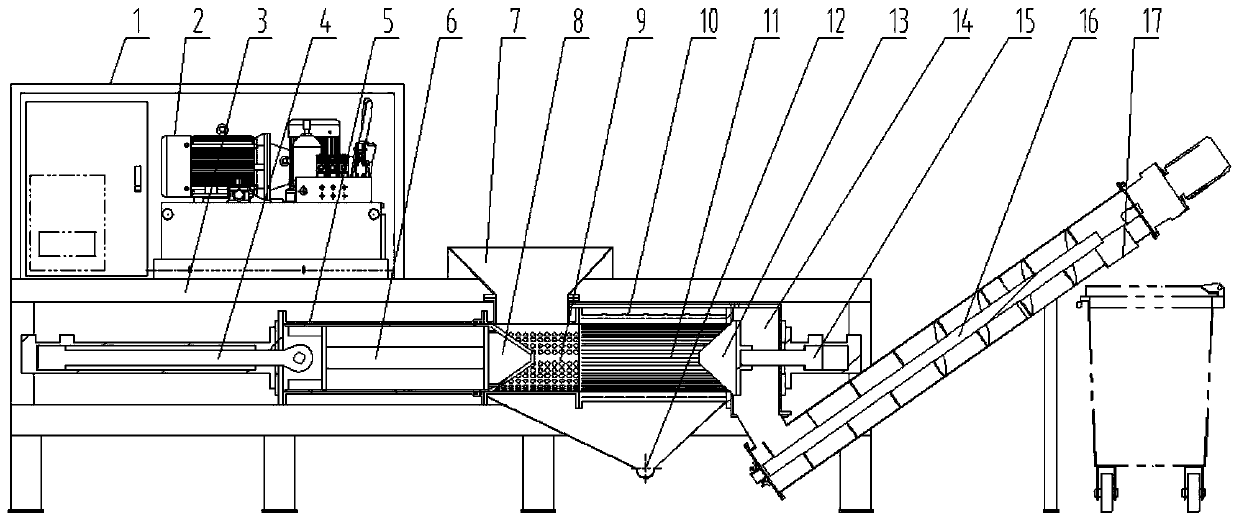

[0020] Referring to the accompanying drawings, a high-speed horizontal reciprocating fruit and vegetable garbage extrusion dehydrator includes a pump station support (1), a hydraulic power station (2), a main frame (3), an extrusion master cylinder (4), and an extrusion barrel Cavity (5), extrusion column (6), feed inlet (7), extrusion main bit (8), primary screen drum (9), screen drum casing (10), secondary screen drum (11) , drainage groove (12), extrusion auxiliary drill bit (13), slag discharge chamber (14), extrusion auxiliary oil cylinder (15), discharge screw conveyor (16), discharge port (17).

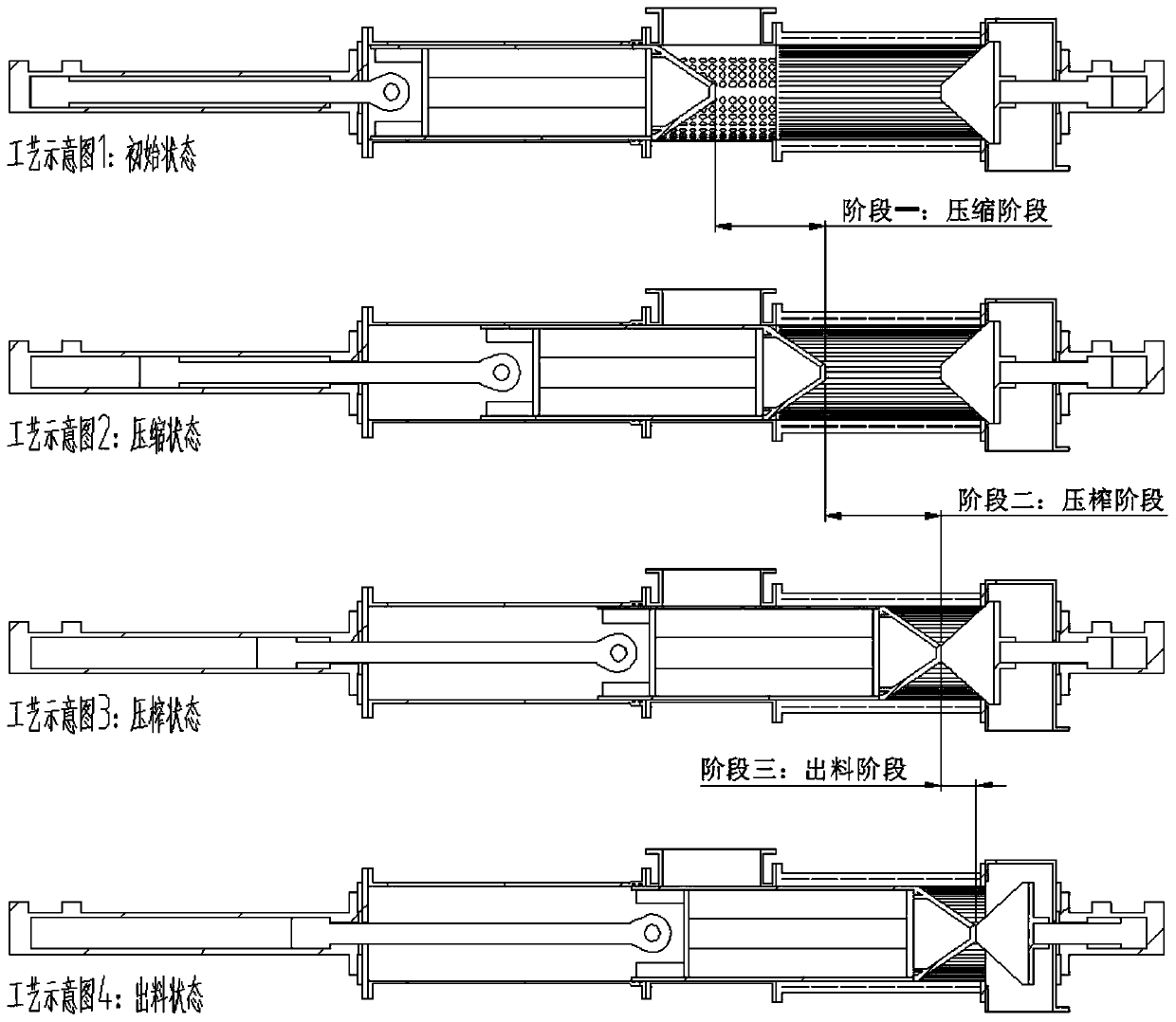

[0021] The extrusion main cylinder (4) and the extrusion auxiliary cylinder (15) are installed on the same horizontal axis, controlled by the hydraulic power unit (2), and are in the initial state, compression state, extrusion state, In the discharge state, the four processes perform reciprocating actions; when running without load, the axial movement speed of the extrusion mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com