Low-nitrogen burner and fuel gas device thereof

A low-nitrogen burner and air technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of unfavorable low-nitrogen environmental protection emission requirements, difficult product performance stability, and high gas emissions, so as to improve energy Conversion efficiency, achieving low nitrogen oxide emissions, and reducing CO emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

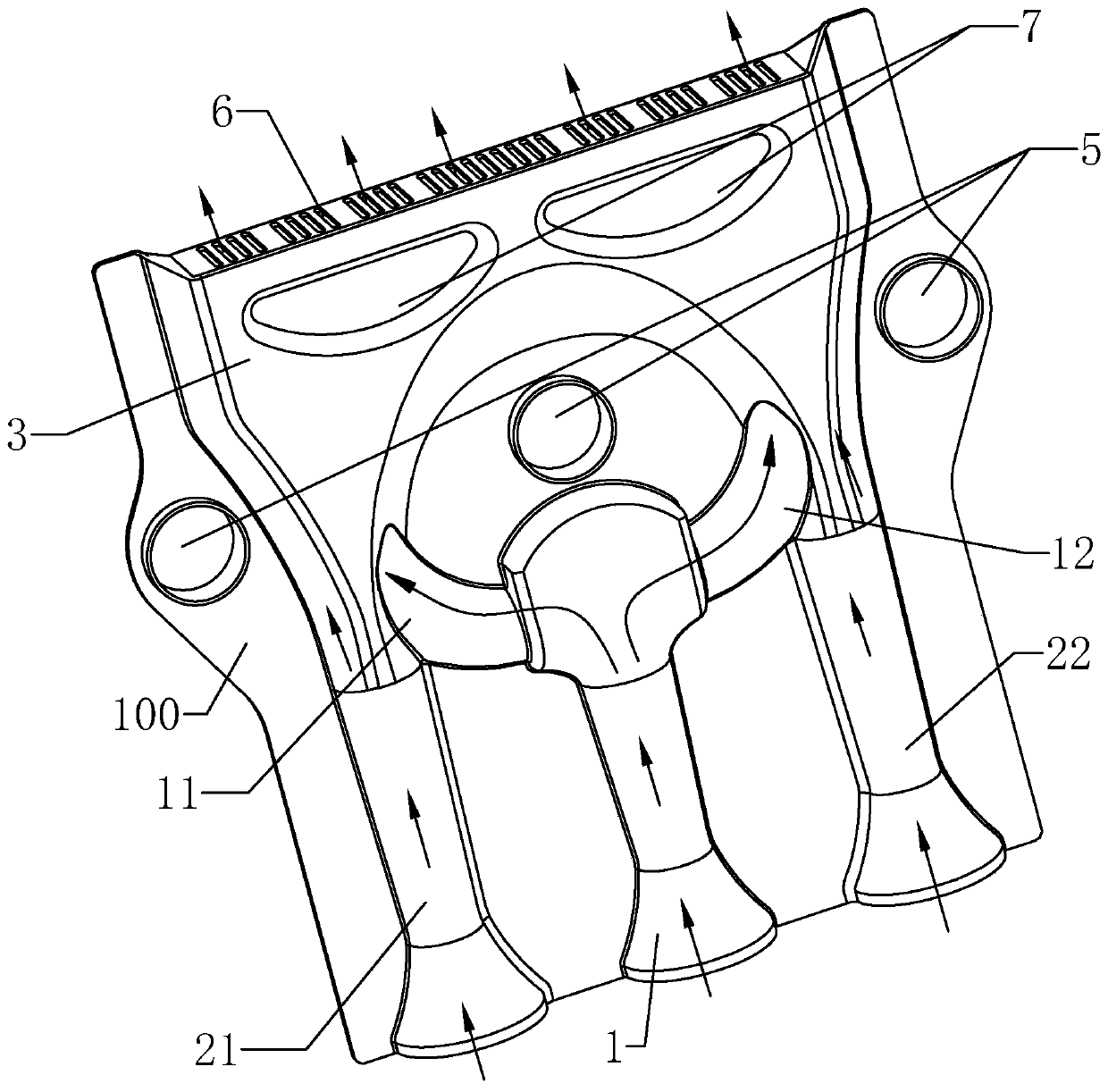

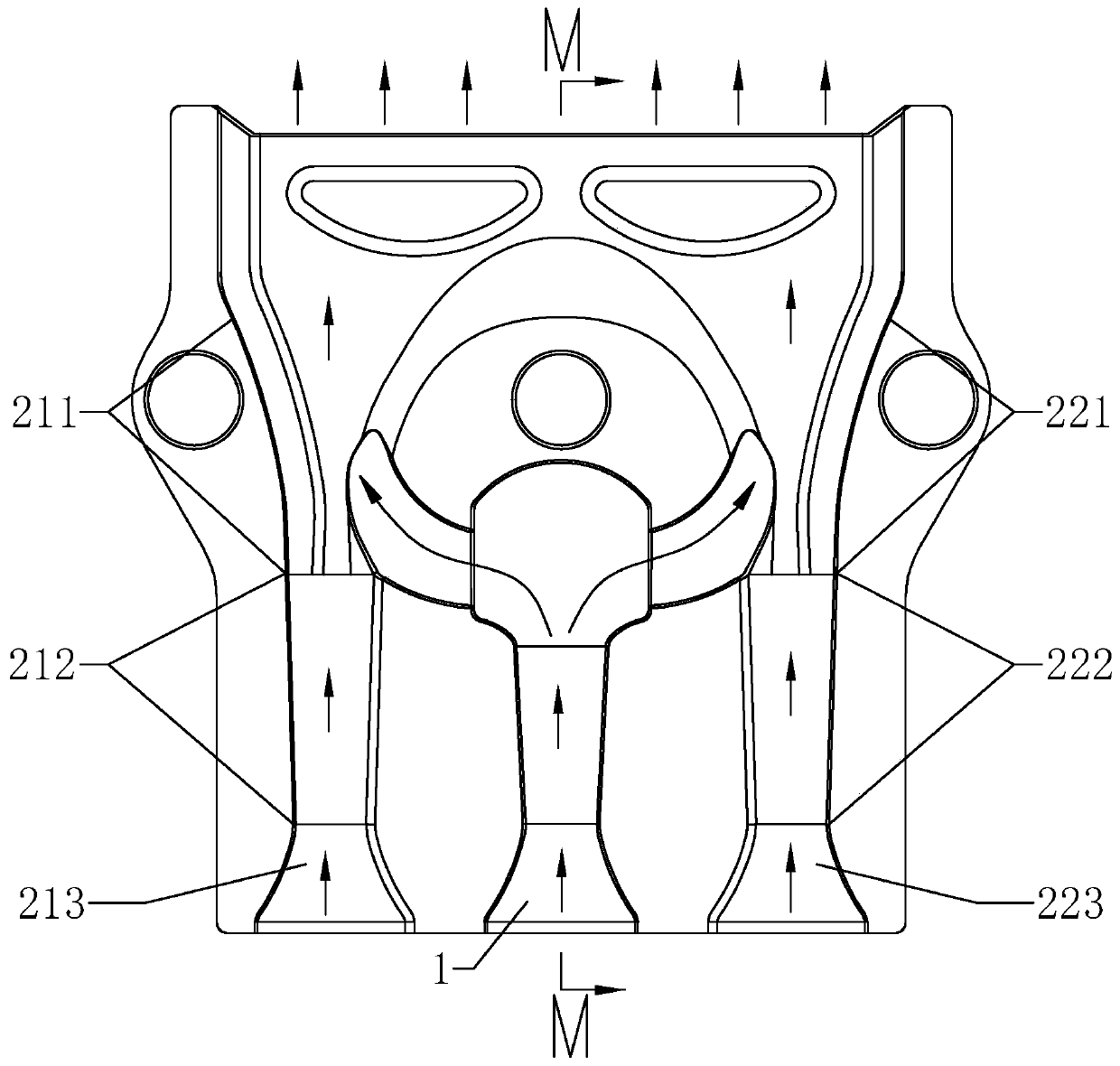

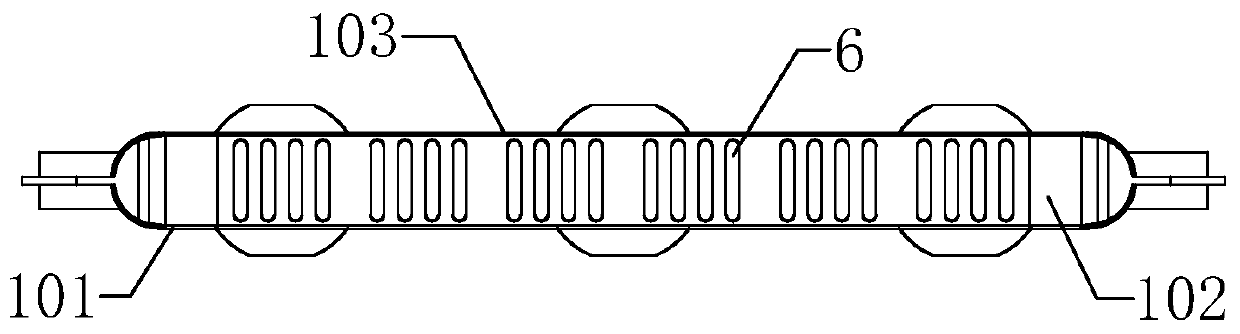

[0012] combine Figure 1 to Figure 4 , a low-nitrogen burner, including a housing 100, the housing 100 is provided with an injection channel 1, a split channel (11, 12), an air supply channel (21, 22), a diffusion mixing chamber 3, and the housing 100 There are also three water flow channels 5 arranged through the thickness direction; the air inlet of the injection channel 1 is used to introduce gas and air, and the gas outlet end of the injection channel 1 passes through the shunt channel (11, 12) and the air supply channel ( 21, 22), the diffuser mixing chamber 3 communicates, the air inlet of the air supply passage (21, 22) is used to introduce air, the air outlet of the air supply passage (21, 22) communicates with the diffuser mixing chamber 3, and the housing 100 A fire outlet 6 communicating with the diffuser mixing chamber 3 is provided on the top of the tank.

[0013] The present invention is provided with an injection channel 1, and the gas nozzle is correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com