Combustible gas engine

A gas engine and gas technology, used in combustion engines, internal combustion piston engines, gaseous engine fuels, etc., can solve the problems of easy pressure detonation and unbearable engine cylinders, achieve smooth operation, avoid waste, and high resistance to detonation impact effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] Specific embodiment 1 of the combustible gas engine of the present invention: In this embodiment, hydrogen is used as an example to introduce the structure and working principle of the combustible gas engine of the present invention. Based on the structure of the combustible gas engine of the present invention, in other embodiments, the combustible gas engine of the present invention can also be used as fuel, such as methane.

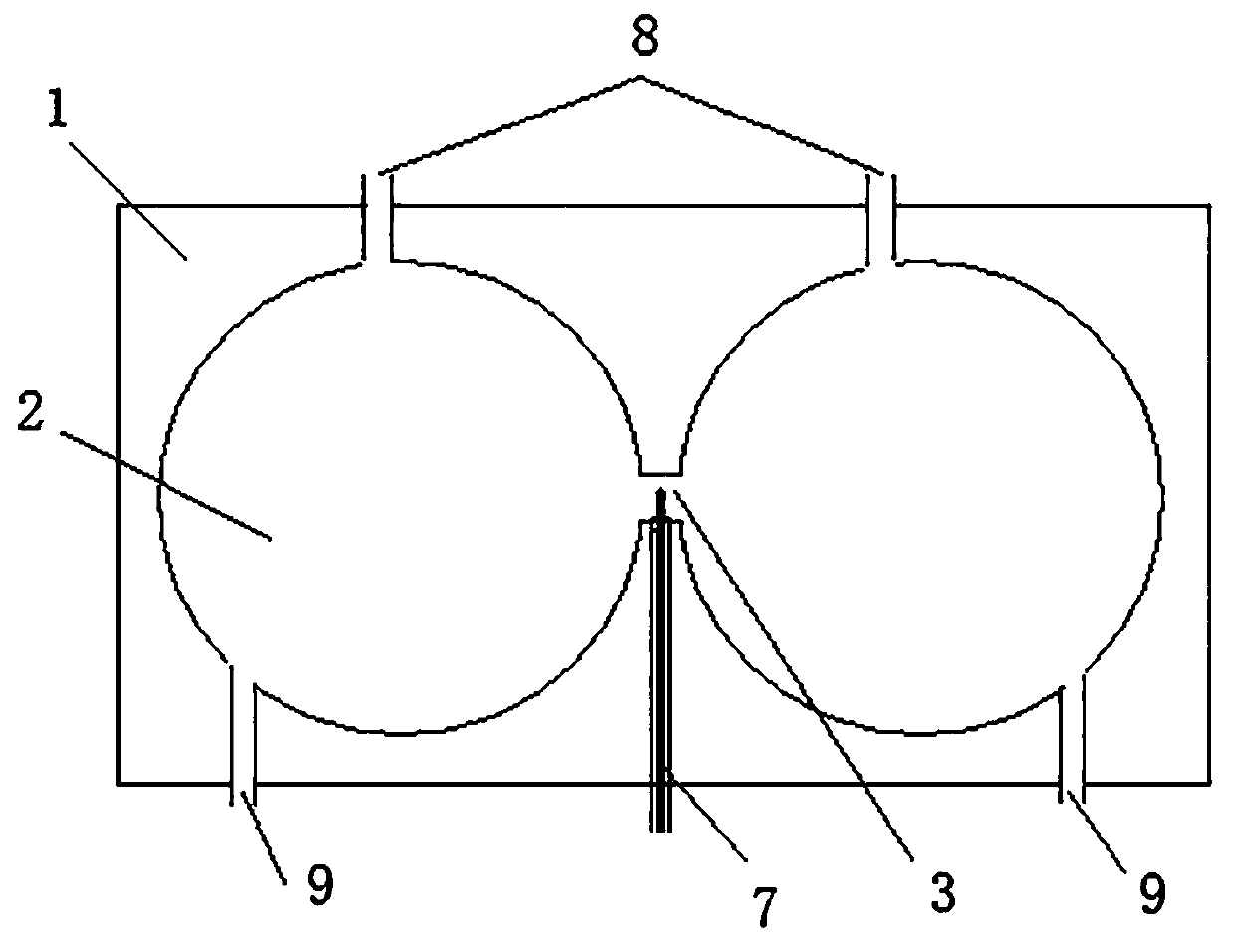

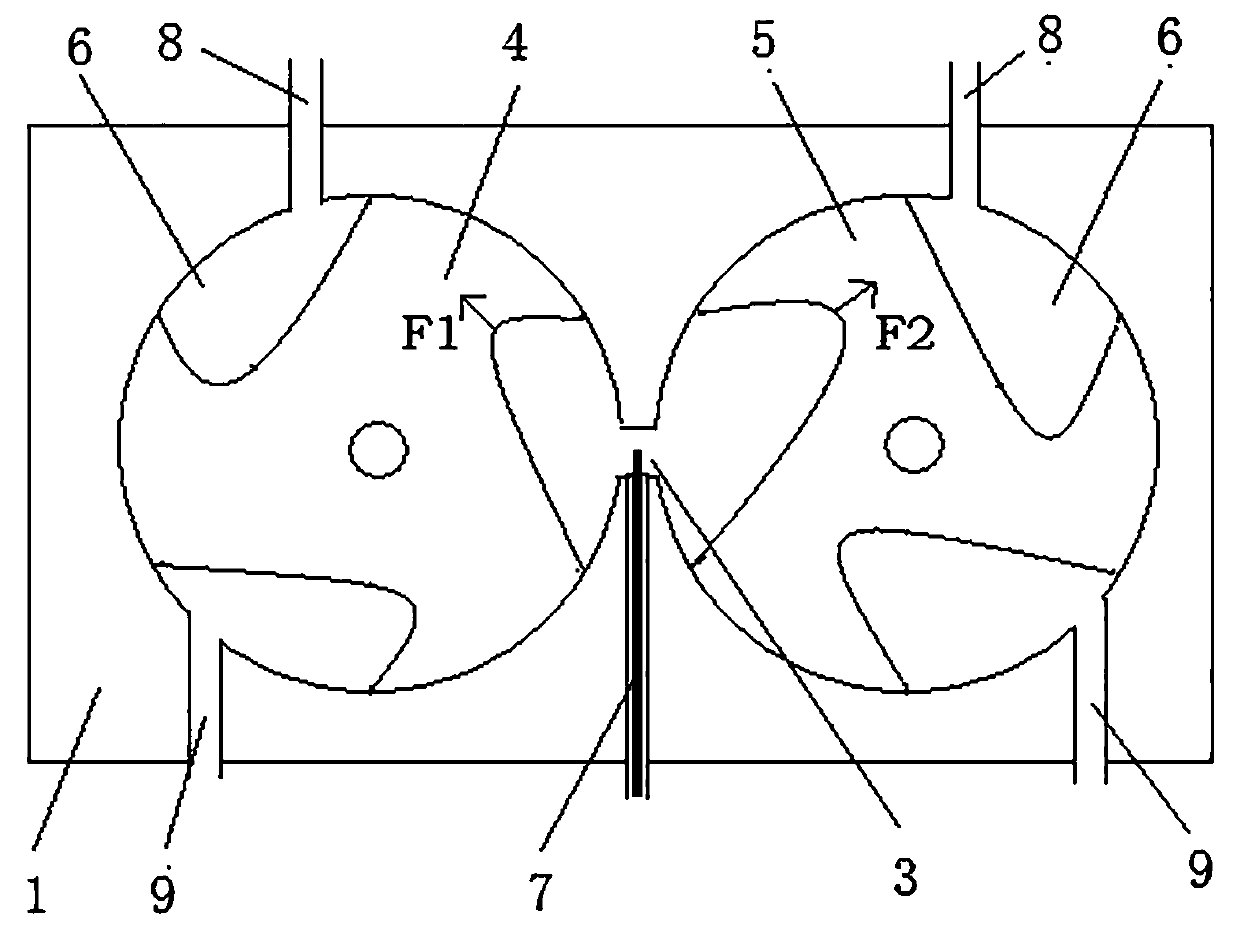

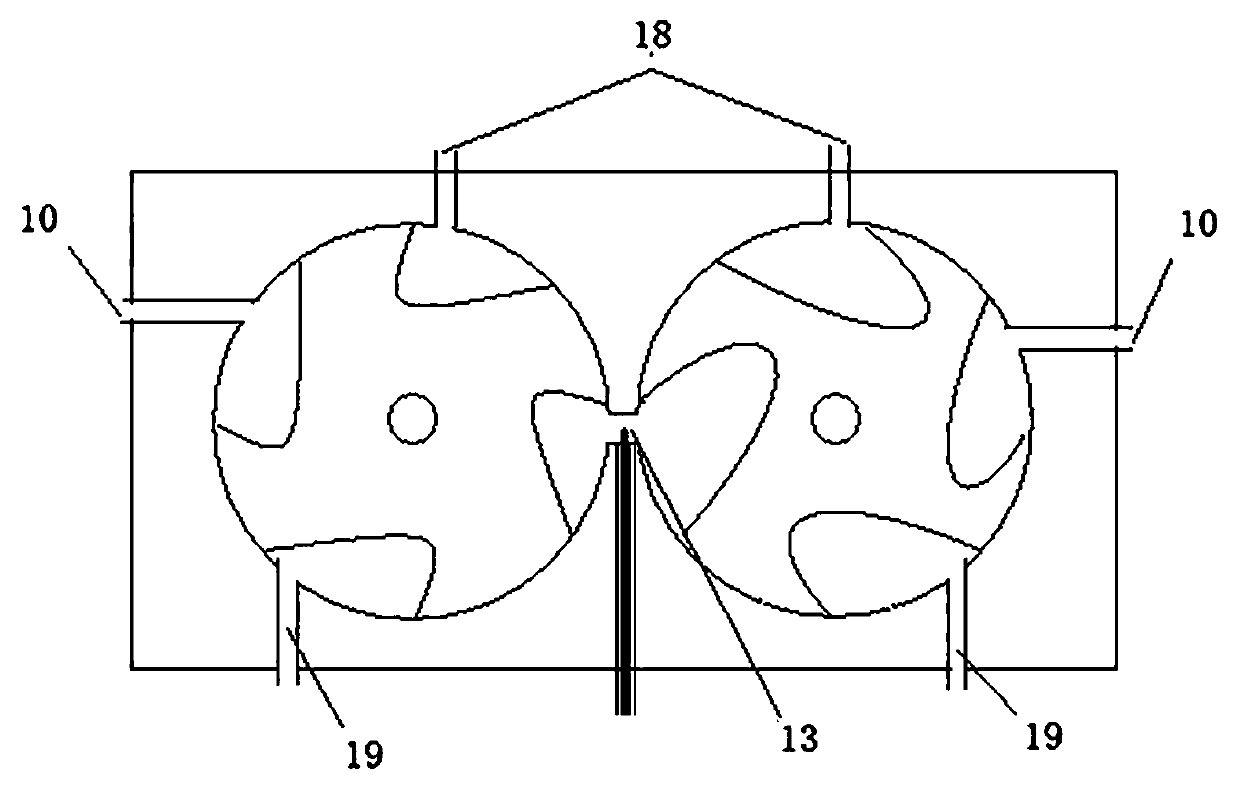

[0035] Such as figure 1 As shown, the combustible gas engine includes a casing 1, and a starting unit is arranged in the casing 1. The starting unit includes a pair of rotating chambers 2 opened on the casing 1, and a communication channel 3 is provided adjacent to the two rotating chambers 2. The communication passage 3 connects the pair of rotating chambers 2 . Such as figure 2 As shown, the engine unit also includes rotors installed in each rotating cavity 2, the axes of the two rotors are parallel and the diameters are equal, and the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com