Internal and external mixed heating type continuous carbonizing device

The technology of a carbonization device and a carbonization chamber is applied in the field of continuous carbonization devices with mixed heating inside and outside. The effect of production efficiency, reducing work intensity and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

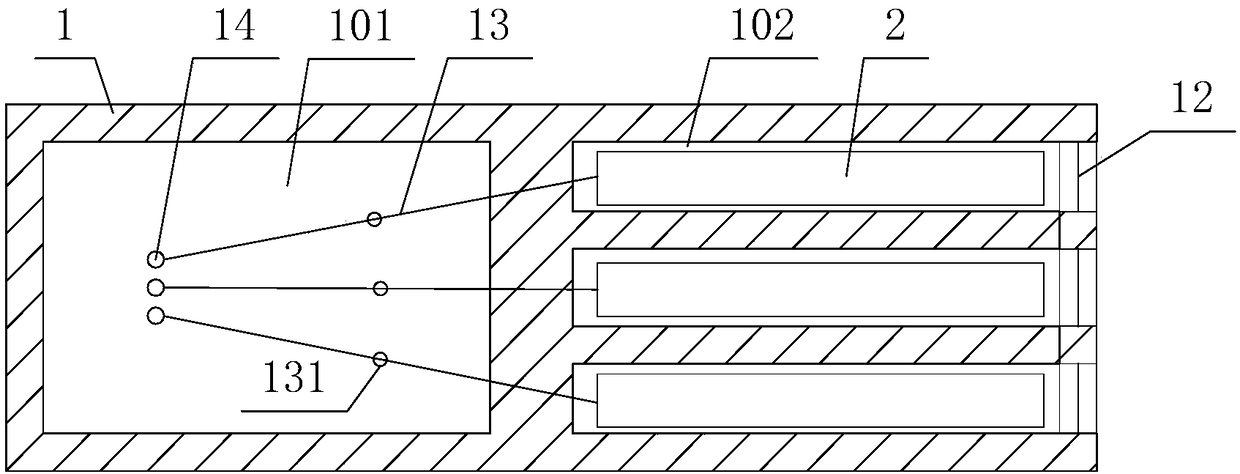

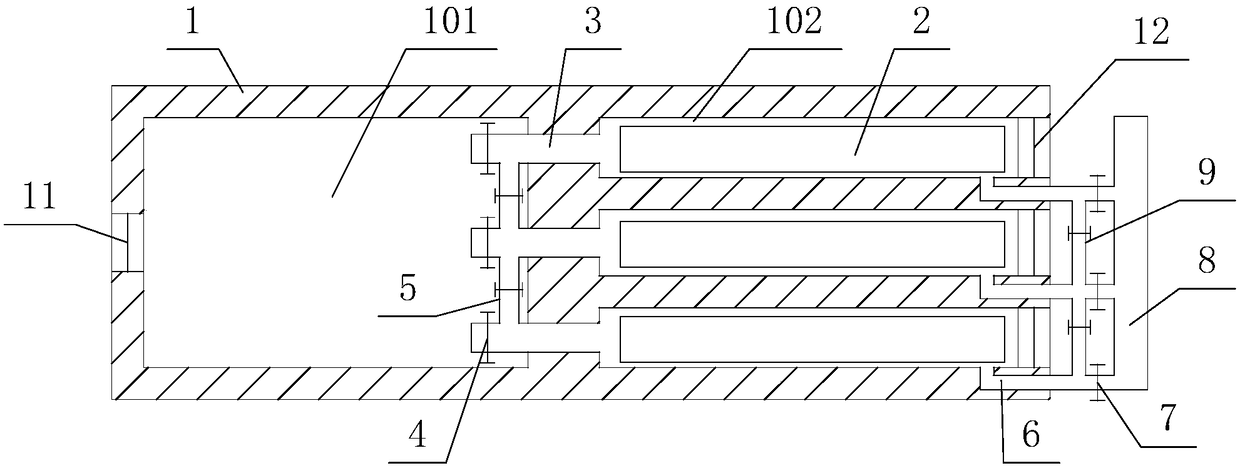

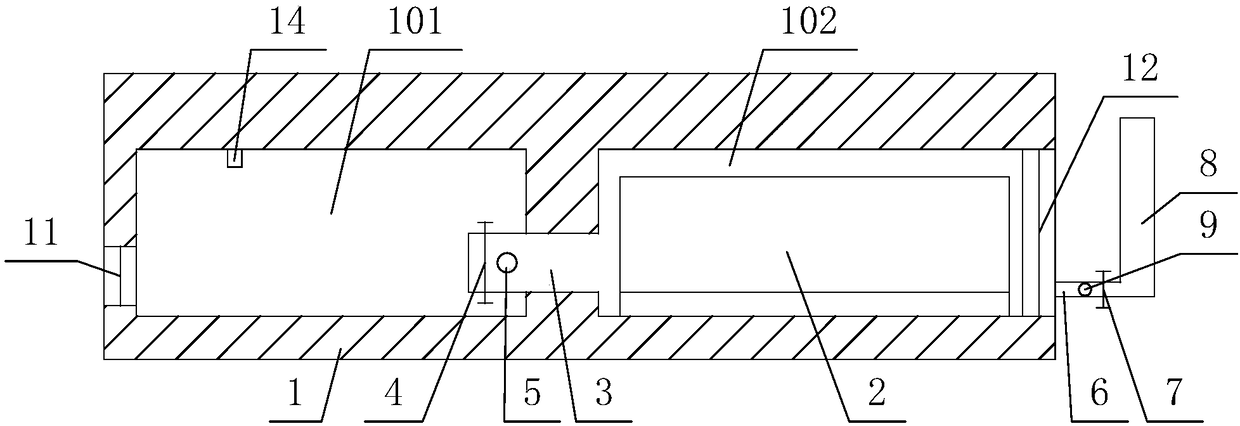

[0052] Such as Figure 1 to Figure 3 As shown, the internal and external mixed heating continuous carbonization device provided by the embodiment of the present invention includes a furnace body 1 and a material box 2 .

[0053] The furnace body 1 is provided with a combustion chamber 101 and a carbonization chamber 102 for accommodating the material box 2 .

[0054] There are at least two carbonization chambers 102 arranged side by side along the horizontal direction.

[0055] In this embodiment, three carbonization chambers 102 are taken as an example for illustration.

[0056] Such as figure 2 and image 3 As shown, the three carbonization chambers 102 are all arranged adjacent to the combustion chamber 101 . In this embodiment, all the carbonization chambers 102 are located on the same side of the combustion chamber 101 in the horizontal direction. A furnace door 11 is provided on a side of the combustion chamber 101 away from the carbonization chamber 102 .

[0057...

Embodiment 2

[0097] The difference between this embodiment 2 and embodiment 1 is: in this embodiment, if Figure 9 As shown, all the carbonization chambers 102 are located directly above the combustion chamber 101 .

[0098] In this embodiment, four carbonization chambers 102 are provided. The bottom of one end of the four carbonization chambers 102 communicates with the combustion chamber 101 through the heat conduction pipe 3 , and a flue 6 is respectively arranged at the lower side of the other end of the four carbonization chambers 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com