Utilization method of thermal cracking waste residue oil

A technology of thermal cracking and waste residue, applied in the direction of mixing methods, chemical instruments and methods, dissolution, etc., can solve the problems of insufficient combustion, viscosity, increased production costs, etc., and achieve the effect of reducing secondary pollution and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

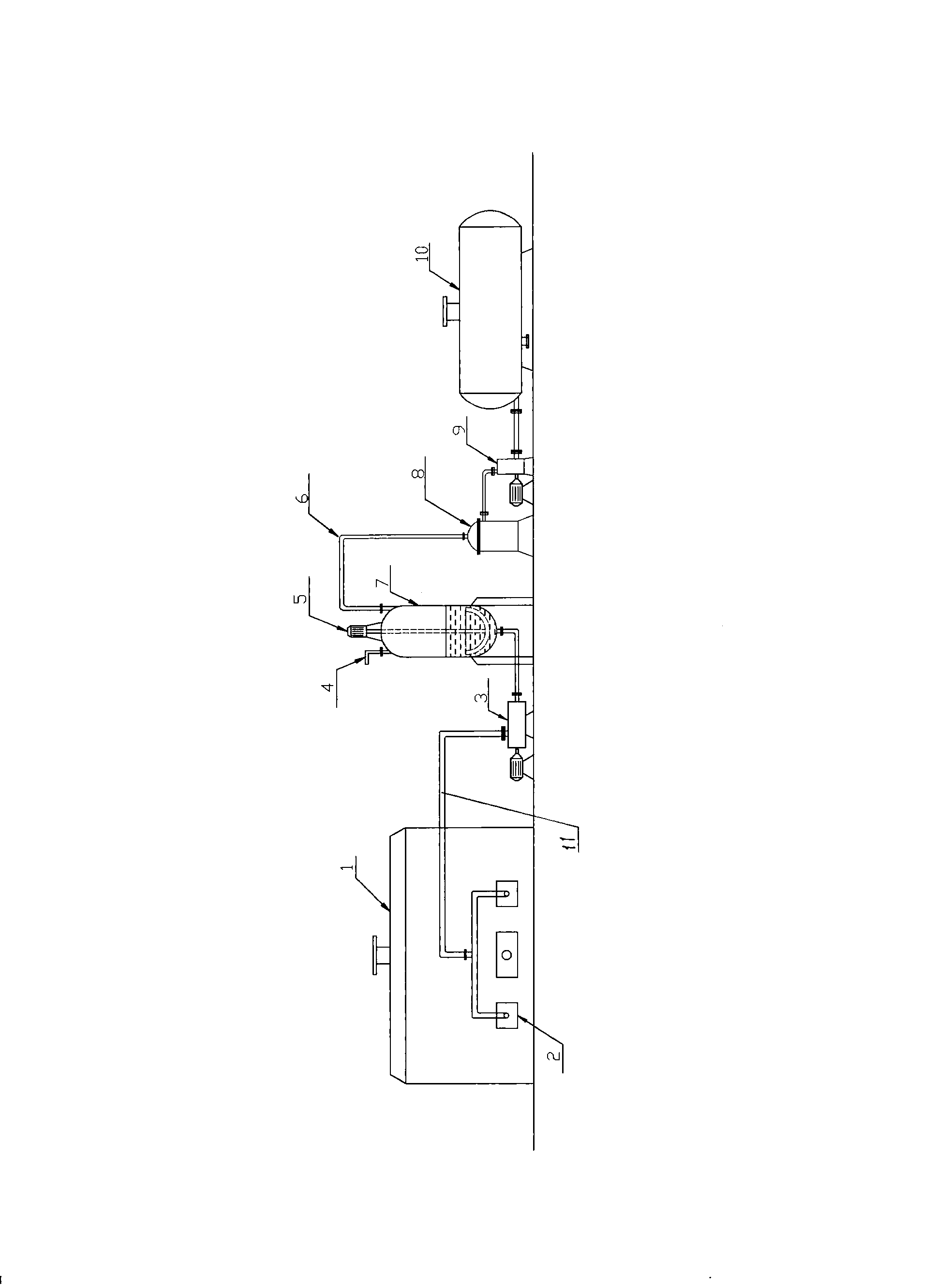

[0007] The system of the present invention is as figure 1 As shown, the system mainly includes a combustion furnace 1, a fuel oil burner 2, a residual oil emulsifier 3, a mixing tank 7, a filter 8, an oil delivery pump 9, and a residual oil tank 10. The residual oil in the residual oil tank 10 is passed through The oil delivery pump 9, filter 8 and oil delivery pipe 6 enter the mixing tank 7, and at the same time, add 20-30% of the total amount of mixed liquid water into the mixing tank 7 through the water delivery pipe 4, and then enter the residual oil emulsifier 3 after being fully mixed by the mixer 5 , so that the residual oil can be dispersed, emulsified, and homogenized multiple times under the cutting, extrusion, and vibration of high tangential speed and high-frequency mechanical energy, so that the residual oil can become a stable, fine and homogeneous emulsified fuel oil, and then enter the combustion through the emulsified oil pipe 11 The oil burner 2 of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com