Electric proportional pressure valve

A proportional pressure valve, electrical technology, applied in the field of proportional pressure valve, can solve the problems of slow response, short service life, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

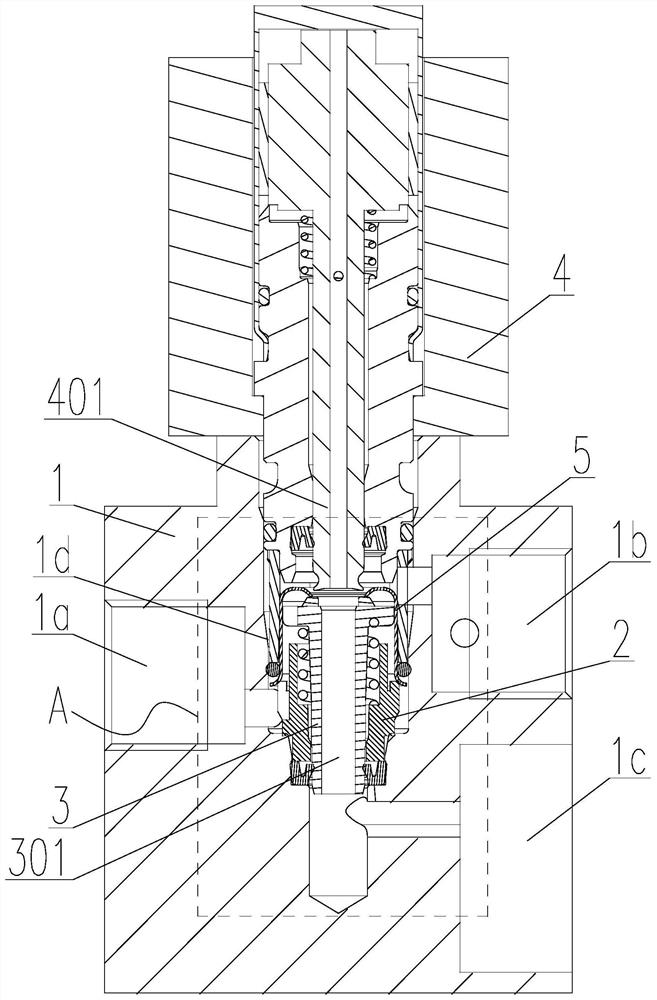

[0058] Such as Figure 1-4 Shown, an electric proportional pressure valve, including:

[0059] The valve body 1 has a valve chamber 1d, a P1 port 1a, a P2 port 1b, and a P3 port 1c;

[0060] The valve seat 2 has a valve hole 201, and the valve seat 2 is fixed at the bottom end of the valve cavity 1d;

[0061] The valve core 3 has a central hole 301 through it, and the bottom end of the valve core 3 is inserted in the valve hole 201 and is slidably connected with the valve hole 201;

[0062] The proportional electromagnet 4 is set on the top of the valve cavity 1d and fixed on the valve body 1;

[0063] The fixed cover 5 is fixed in the valve chamber 1d, and is sleeved on the outside of the valve seat 2. The top of the fixed cover 5 has a top edge 501, and the fixed cover 5, the valve seat 2 and the valve core 3 are formed between the fixed cover 5 and the valve core 3. The first cavity 6 communicated with P1 port 1a, the position between the proportional electromagnet 4 and...

Embodiment 2

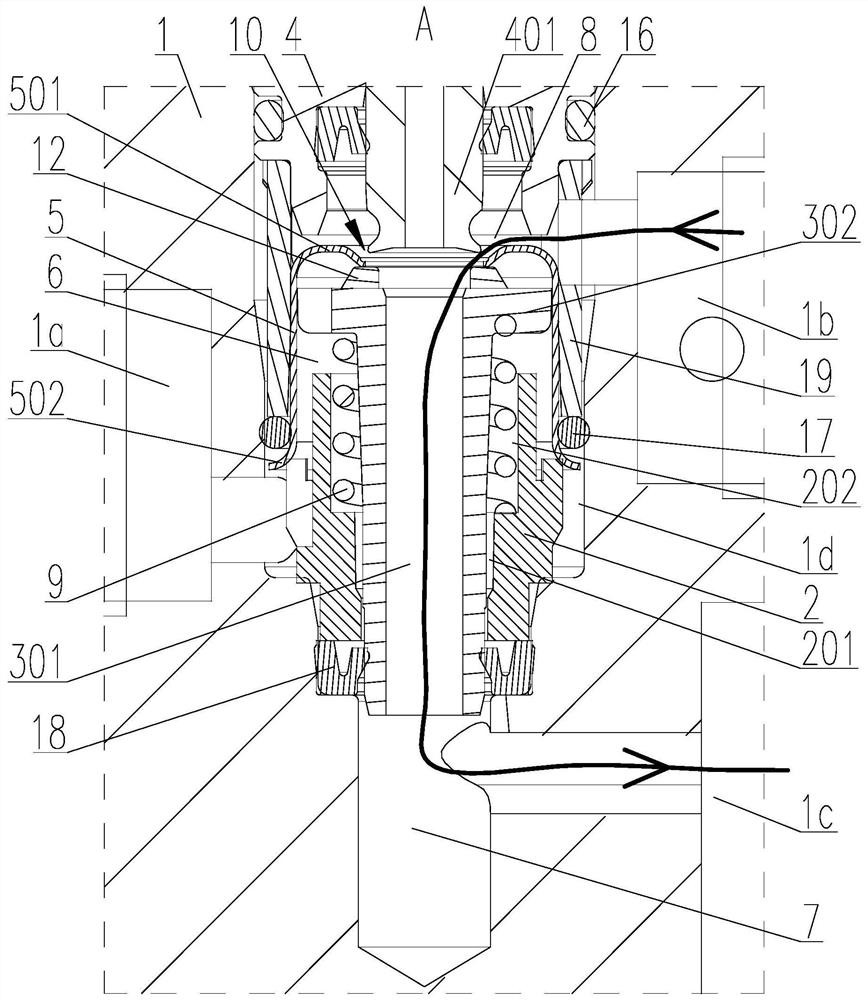

[0070] The sealing unit includes a gasket 12, the gasket 12 is fixed on the top end surface of the valve core 3, and the top opening of the central hole 301 is located in the gasket 12;

[0071] Such as figure 2 As shown, in the first working state, the top edge 501 of the fixed cover 5 is against the gasket 12, that is, the valve core 3 is firmly pressed against the top edge of the fixed cover 5 by the gasket 12 under the action of the elastic element 9 501 to ensure that the first cavity 6 and the second cavity 7 are kept isolated from each other; the push rod 401 is separated from the gasket 12 to ensure that the first gap 10 formed between the push rod 401 of the proportional electromagnet 4 and the valve core 3 can Make the upper opening of the central hole 301 communicate with the second chamber 7;

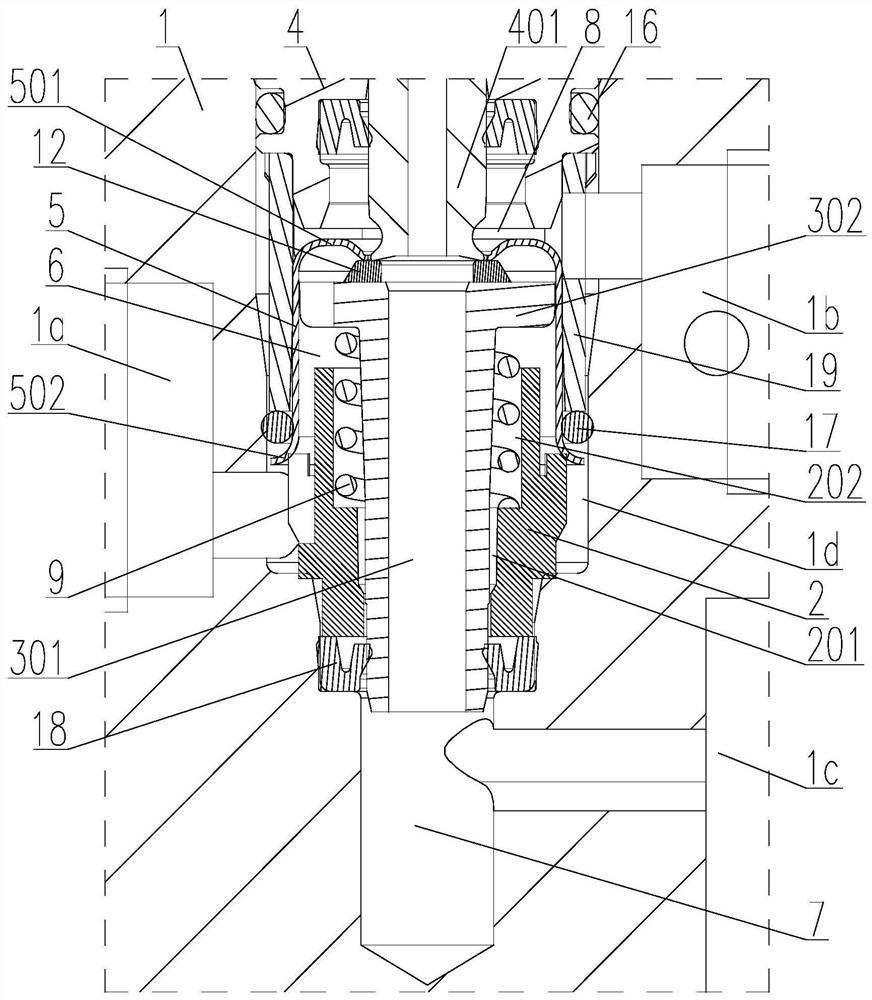

[0072] Such as image 3 As shown, during the second working state, the top edge 501 of the fixed cover 5 is against the sealing gasket 12, that is, the valve core 3 makes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com