AGV trackless trolley drive wheel automatic correction device

An automatic correction and driving wheel technology, which is applied in the direction of non-deflectable wheel steering, motor vehicles, vehicle parts, etc., can solve the problems of hidden installation parts, disorderly starting, difficult operation, etc., and achieve stable work and long service life Long, easy-to-program effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

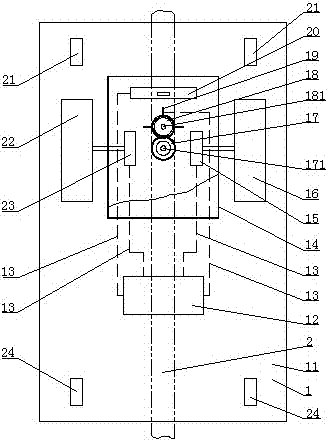

[0007] see figure 1 , the present invention comprises dolly 1 and magnetic strip 2, and described dolly 1 comprises car body 11, on-board controller 12, signal line 13, drive assembly housing 14, right driver 15, right drive wheel 16, navigation sensor 20, left Drive wheel 22, left driver 23, two universal wheels 21 and two road wheels 24, said on-board controller 12 is equipped with programmable logic controller PLC, also includes driving gear 17, driven gear 18, rotating shaft I171 , rotating shaft II181 and angle correction potentiometer 19, described rotating shaft I171 and rotating shaft II181 are contained on the vehicle body 11, and described rotating shaft I171 is contained in the middle position between left driving wheel 22 and right driving wheel 16, described driving gear 17 is fixedly installed in the drive assembly housing 14, and the driving gear 17 is mounted on the rotating shaft I171, and the driven gear 18 is mounted on the rotating shaft II181, and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com