Hydraulic lifting system for ship

A hydraulic lifting and marine technology, applied in the direction of lifting frame, lifting device, ship construction, etc., can solve the problem of less multi-functional ship equipment, and achieve the effect of clear hydraulic principle, improved oil cylinder life, and simple program control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

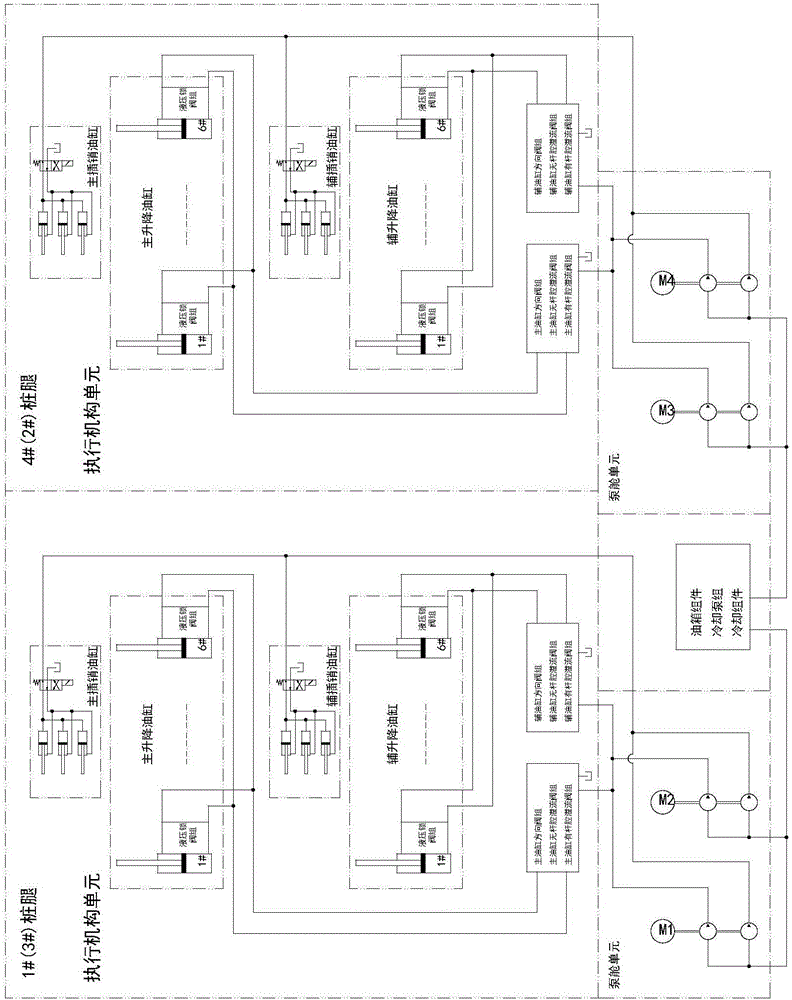

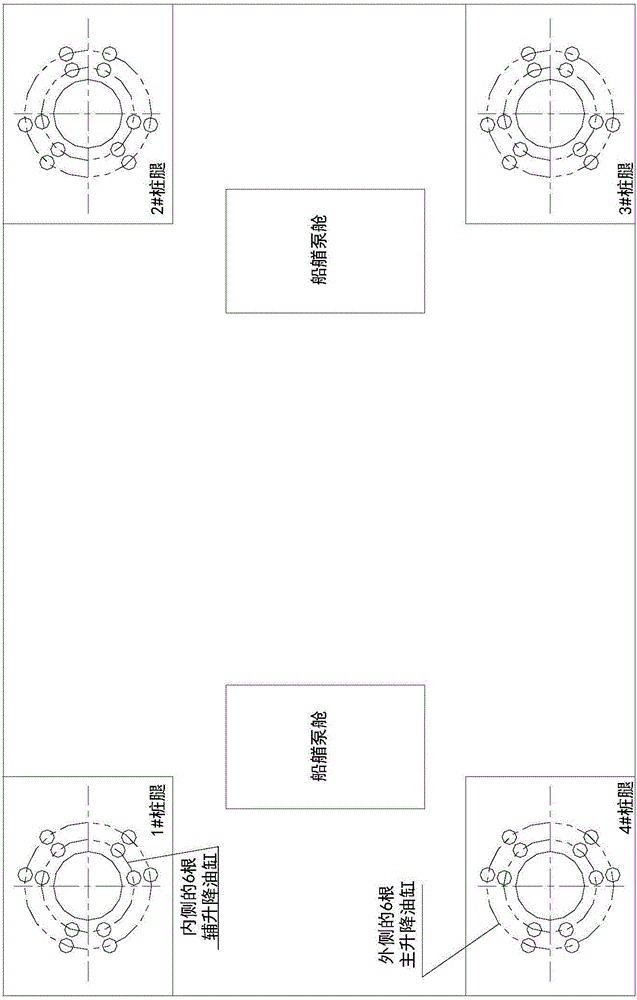

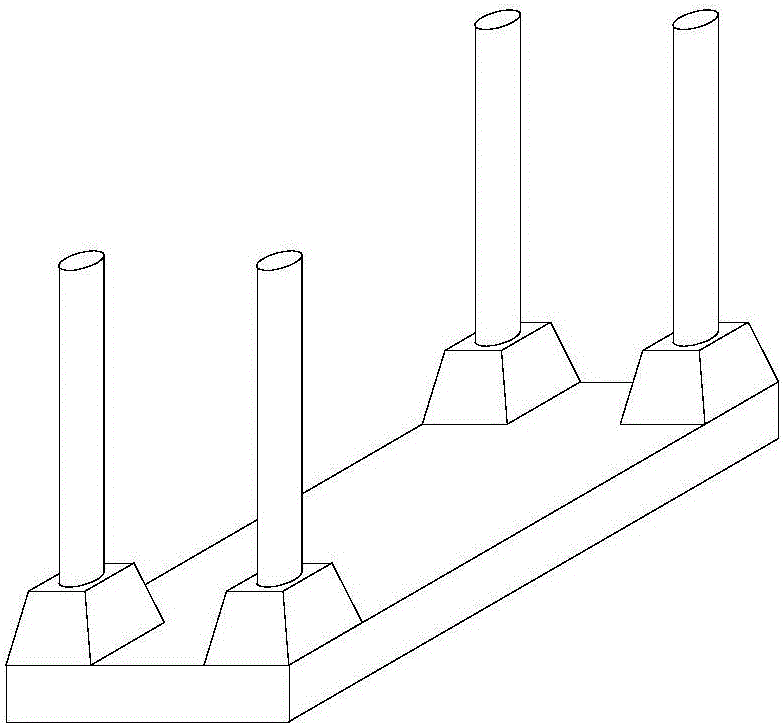

[0017] figure 1 showing the principle of a preferred embodiment of the marine hydraulic lifting system of the present invention, Figures 2A to 2C The structural position of the marine hydraulic lifting system of the present invention is shown. See also figure 1 , Figures 2A to 2C , the whole ship is supported by four pile legs, and the hull is fixed on the pile legs through the upper ring beam bolt and the lower ring beam bolt. The high and low ring beams on the pile legs are synchronously raised and lowered by 6 main lifting cylinders to drive the whole ship up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com