Rotating region detection device, system and detection method

A technology of area detection and slip ring, which is applied in the direction of transportation and packaging, load hanging components, etc., to achieve the effect of low cost, simple and easy transformation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

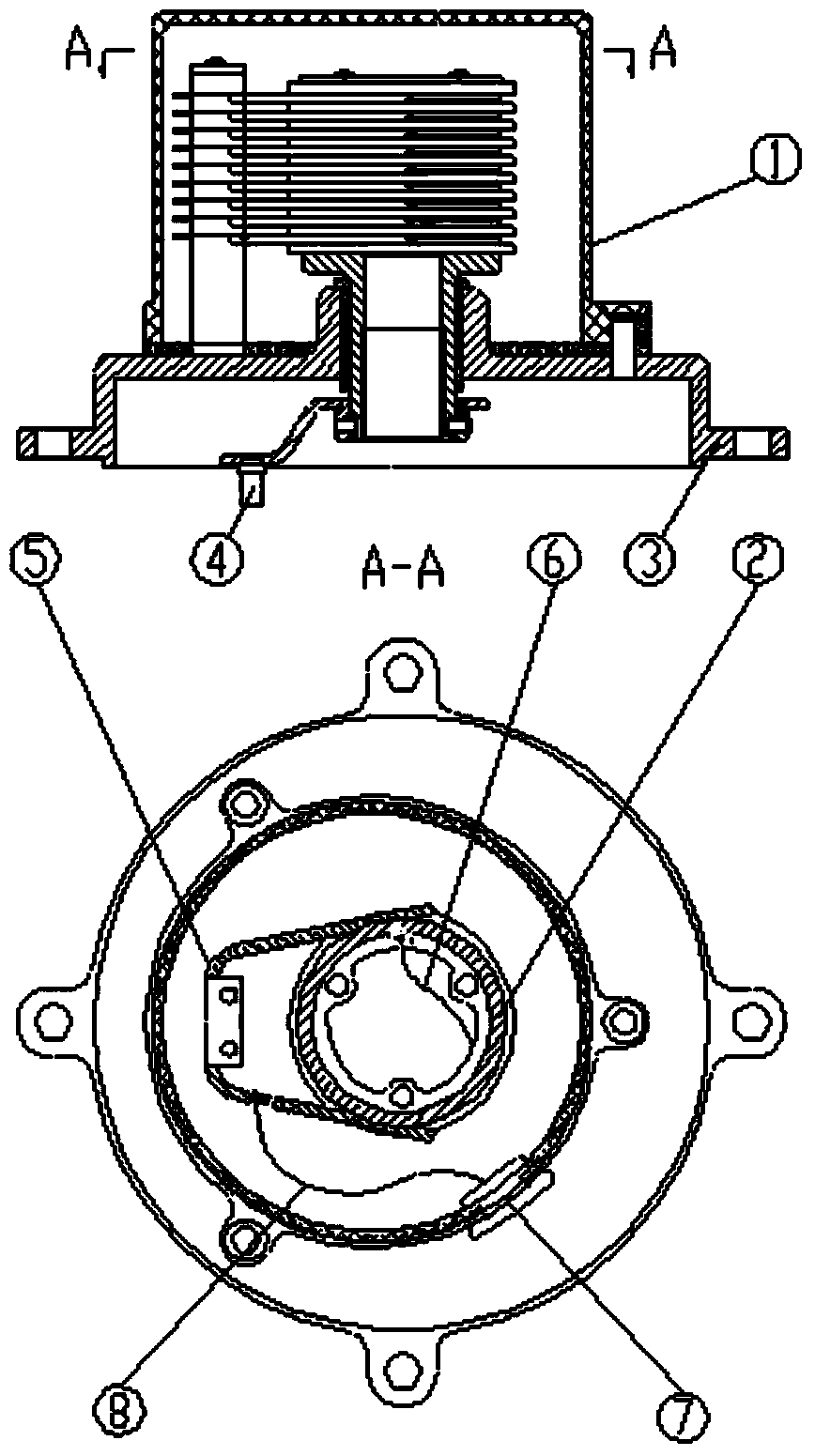

Embodiment 1

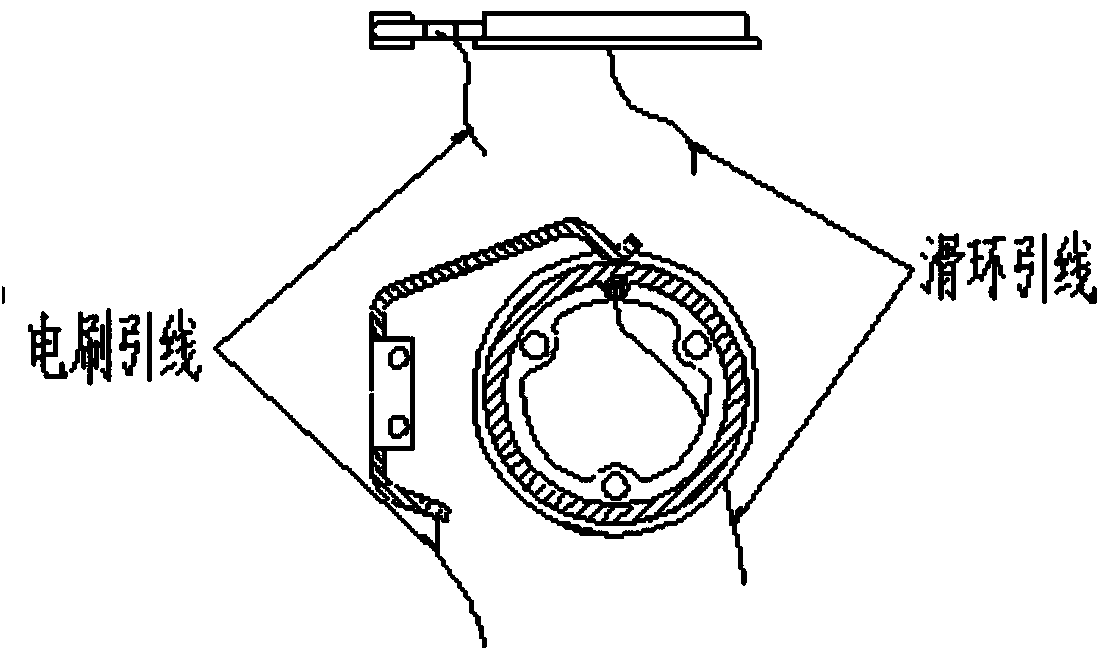

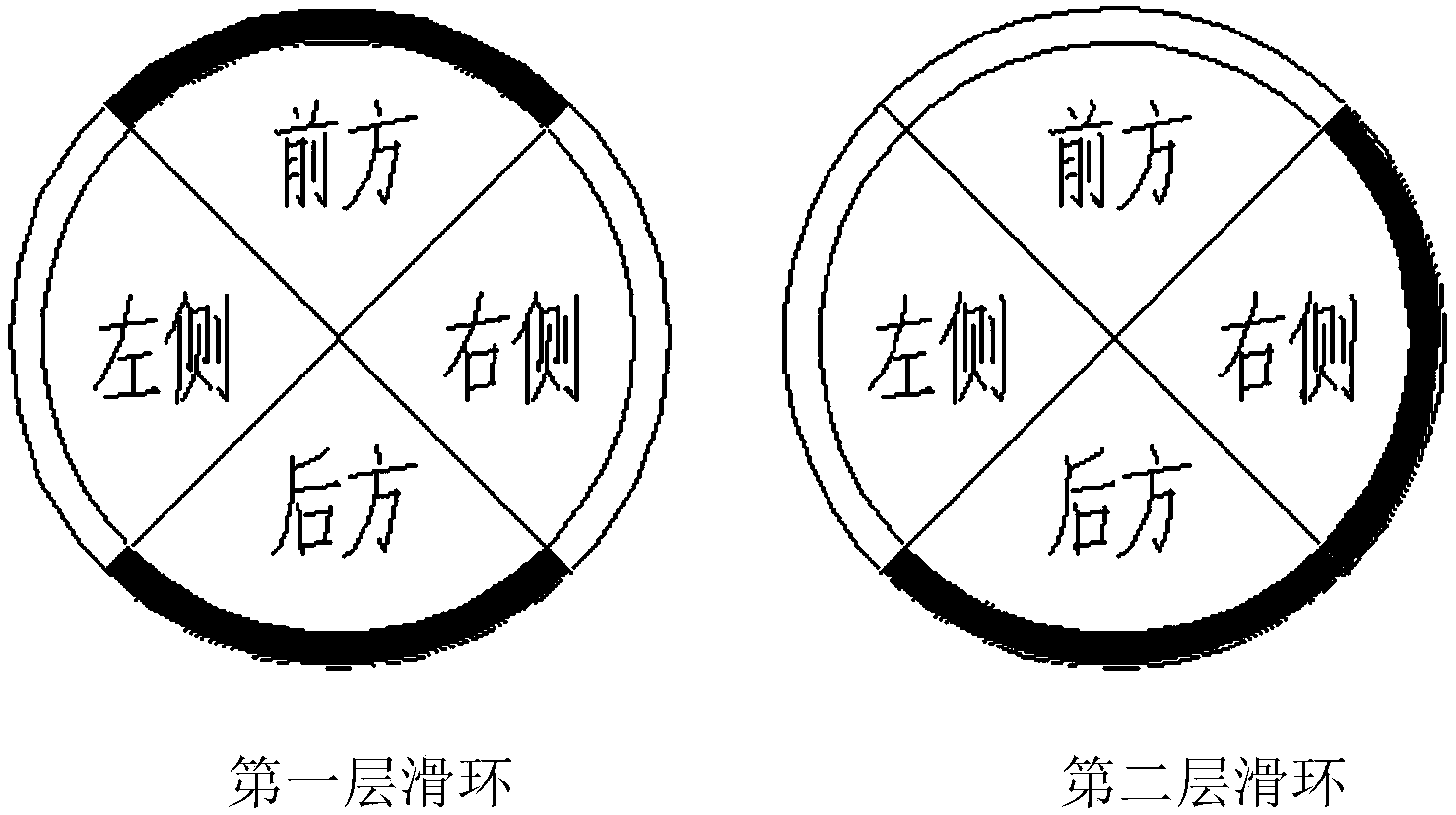

[0031] Such as image 3 As shown, the black slip ring area filled with conductive material is called the conductive part, while the slip ring area not filled with conductive material is called the insulating part. During the relative sliding process of the brush body 5 and the slip ring 2, the brush body 5 passes through the conductive part of the black slip ring and conducts the circuit, and transmits a high-level signal to the controller, which is recorded as 1, and the brush body 5 passes through the insulating part of the non-filled slip ring The circuit is not conducting, and a low-level signal is transmitted to the controller, which is recorded as 0. image 3 The first slip ring and the second slip ring in the front, rear, left and right sides are divided into equal parts, the first slip ring is set as a conductive part at the front and rear, and is set as an insulating part at the left and right . The second slip ring is provided as a conductive part on the right and ...

Embodiment 2

[0034] The following takes the anti-overturn control of the truck-mounted crane as an example for a brief description. In this example, the installation position of the truck-mounted crane is close to the rear side of the cab of the car. For details, see Figure 4 . In order to realize the overturn protection of the truck-mounted crane, the control equipment needs to collect external sensor information, and apply different control functions f in the 90° area of the front, 60° area of the rear, 105° area on the left side, and 105° area on the right side 1 (x,m), f 2 (x,m), f 3 (x,m) and f 4 (x,m) to calculate and limit the moment, if using such as Figure 5 As shown in the structure of the first layer slip ring and the second layer slip ring, the controller collects the first and second slip ring signals to form different level signal combinations. According to the combined information of these level signals, the area where the slewing device is located can be judged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com