A sludge drying device

A sludge drying and drying technology, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low drying power, low drying humidity of materials, and large energy consumption, etc., to achieve Ease of production and maintenance, low follow-up processing costs, and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

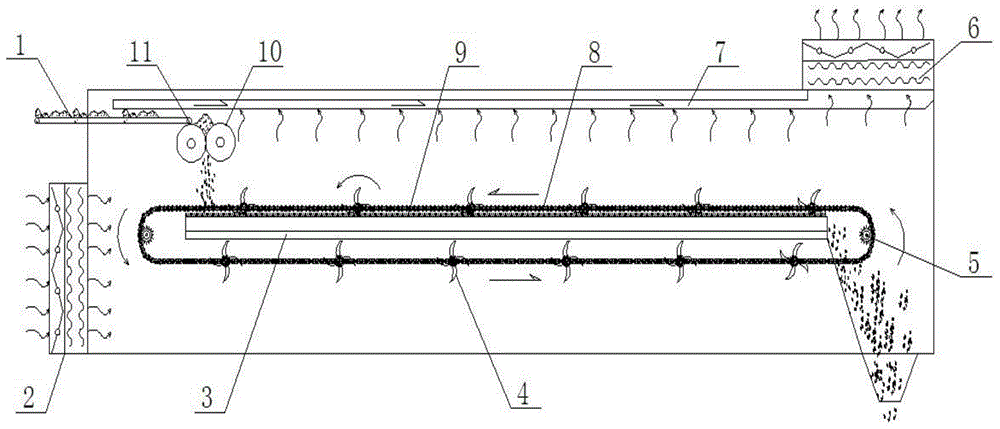

[0027] Such as figure 1 As shown, the sludge drying device includes a squeeze roller 10 installed above the drying heating plate 3 and connected to the sludge conveyor 1;

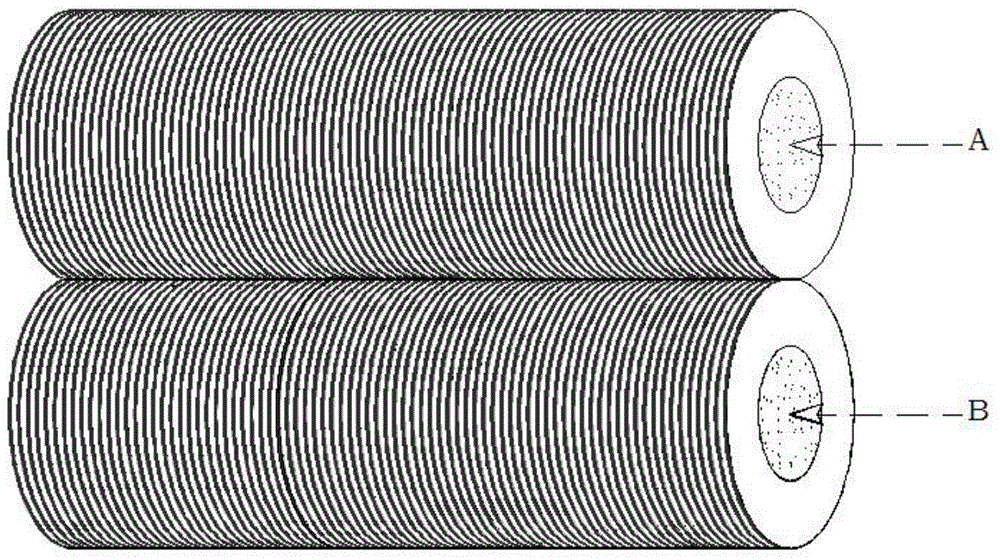

[0028] A chain 8 is installed around the outside of the drying heating plate 3;

[0029] The two ends of described chain 8 are driven by driving sprocket 5;

[0030] A gear bar 9 is arranged between the upper part of the drying heating plate 3 and the chain 8;

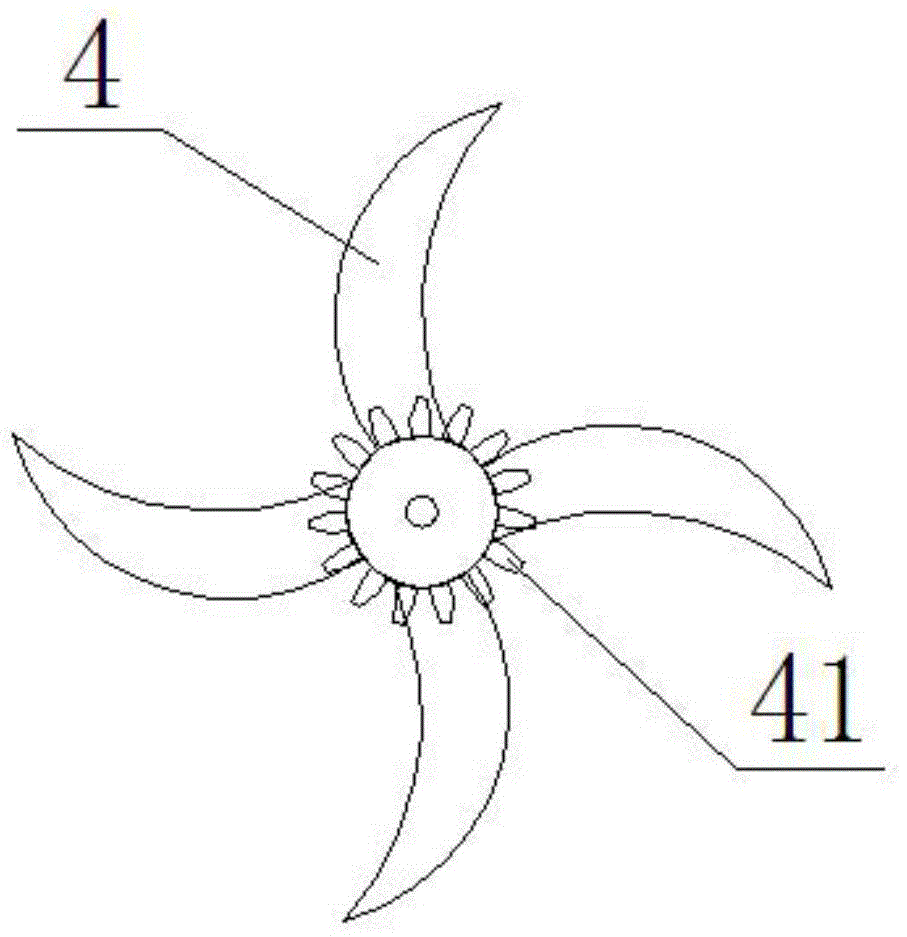

[0031] Rake knives 4 are evenly distributed on the chain 8;

[0032] A rake driving gear 41 is arranged at the axis of the rake 4 and meshes with the gear bar 9 .

[0033] The working process of the sludge drying device is as follows:

[0034] Such as figure 1 As shown, the sludge conveyor 1 transports the sludge to the squeezing roller 10, and the squeezing roller 10 squeezes the sludge into noodles and then falls to the drying heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com