Cooling water supply system and its buffer water supply method

A technology of water supply system and water supply pipe is applied in the field of hot-rolled strip steel rolling to achieve the effect of reducing newly added water systems and realizing the normal operation of water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

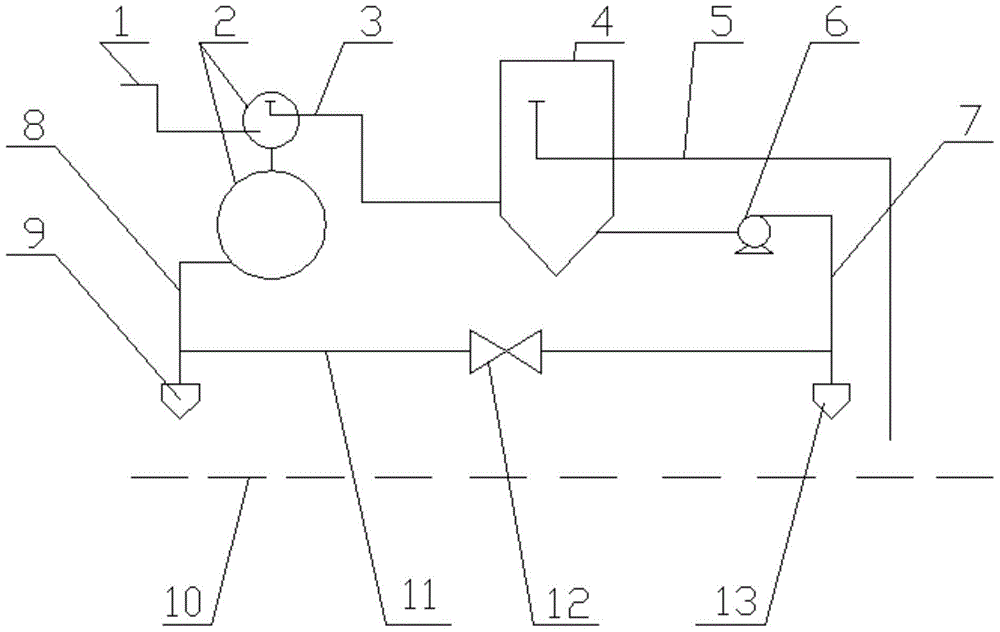

[0056] Taking the strip steel whose steel type is X70 on the hot rolling production line as an example, the steps of the buffer water supply method include:

[0057] S1: Fill the laminar flow water tank 2 and the fast cooling water tank 4 with cooling water through the return water pump, so that the water level in the laminar flow water tank 2 and the fast cooling water tank 4 reaches an overflow height of 7.5m.

[0058] S2: Running the hot rolling production line and the cooling water supply system; wherein, the water supply volume of the laminar flow cooling header 9 of the cooling water supply system is controlled to 3000m 3 / h, the water pressure is 0.07MPa; the water supply control of the fast cooling header 13 of the cooling water supply system is 6000m 3 / h, the water pressure is 0.85MPa.

[0059] S3: When the hot-rolling production line sends out a flying shear loading signal, the speed regulating device performs speed-up adjustment to increase the water supply flow r...

Embodiment 2

[0065] Taking the strip steel whose steel type is X80 on the hot rolling production line as an example, the steps of the buffer water supply method include:

[0066] S1: Fill the laminar flow water tank 2 and the fast cooling water tank 4 with cooling water through the return water pump, so that the water level in the laminar flow water tank 2 and the fast cooling water tank 4 reaches an overflow height of 7.5m.

[0067] S2: Running the hot rolling production line and the cooling water supply system; wherein, the water supply volume of the laminar flow cooling header 9 of the cooling water supply system is controlled to 6000m 3 / h, the water pressure is 0.07MPa; the water supply control of the fast cooling header 13 of the cooling water supply system is 7000m 3 / h, the water pressure is 0.85MPa.

[0068] S3: When the hot-rolling production line sends out a flying shear loading signal, the speed regulating device performs speed-up adjustment to increase the water supply flow r...

Embodiment 3

[0074] Taking the strip steel whose steel type is Q345R on the hot rolling production line as an example, the steps of the buffer water supply method include:

[0075] S1: Fill the laminar flow water tank 2 and the fast cooling water tank 4 with cooling water through the return water pump, so that the water level in the laminar flow water tank 2 and the fast cooling water tank 4 reaches an overflow height of 7.5m.

[0076] S2: Running the hot rolling production line and the cooling water supply system; wherein, the water supply volume of the laminar flow cooling header 9 of the cooling water supply system is controlled to 4400m 3 / h, the water pressure is 0.07MPa; the water supply control of the fast cooling header 13 of the cooling water supply system is 5350m 3 / h, the water pressure is 0.85MPa.

[0077] S3: When the hot-rolling production line sends out a flying shear loading signal, the speed regulating device performs speed-up adjustment to increase the water supply flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com