Gypsum plaster board with convenient construction advantage

A gypsum board and gypsum board technology, which is applied in the field of building decorative boards, can solve the problems of high gypsum board height and no guidance scheme is given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

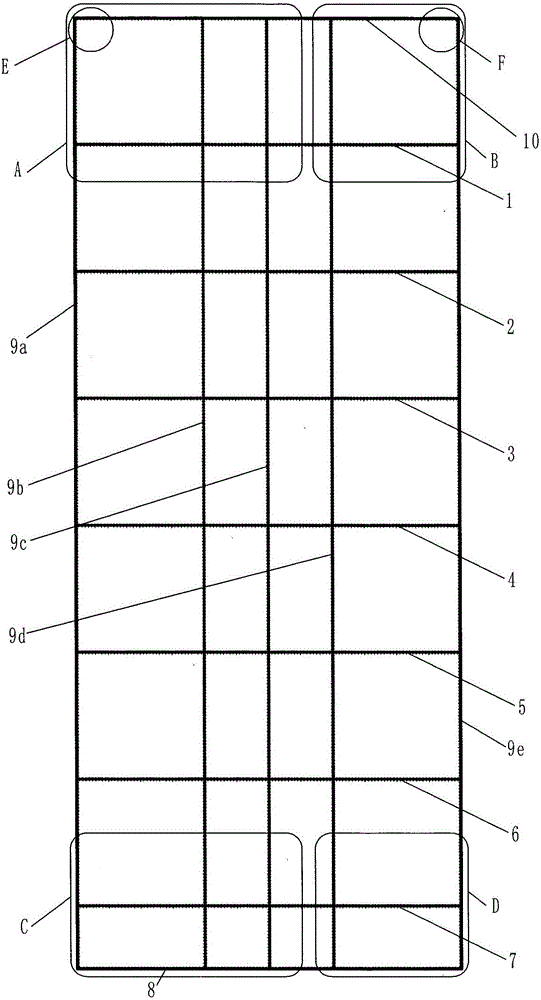

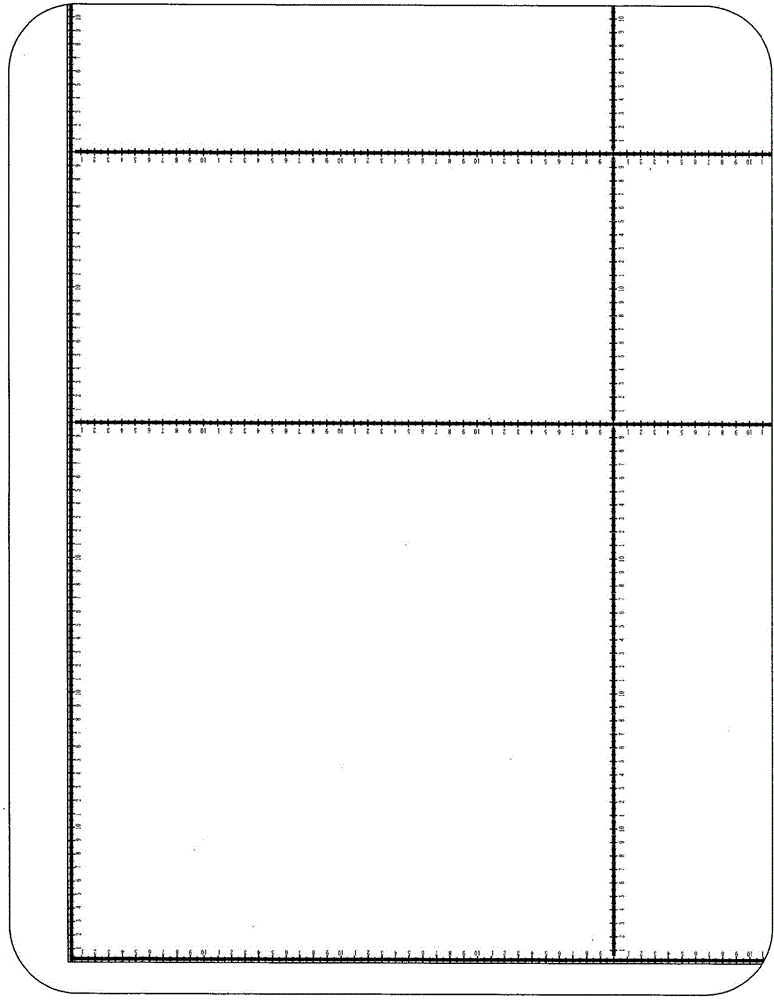

[0023] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7As shown, the first embodiment of the gypsum board of the present invention has a gypsum board and a protective paper, and the specification of the gypsum board is: a width of 120 centimeters, a length of 300 centimeters, and a plate-like rectangle, characterized in that: for The specifications are paper-faced gypsum boards with a width of 120 cm and a length of 300 cm. The protective paper is provided with horizontal scale lines 10, first horizontal scale lines 1, and 120 cm in length parallel to each other from top to bottom. The second horizontal scale line 2 , the third horizontal scale line 3 , the fourth horizontal scale line 4 , the fifth horizontal scale line 5 , the sixth horizontal scale line 6 , the seventh horizontal scale line 7 , and the bottom horizontal scale line 8 . The protective paper is successively provided with parallel longitudinal scale lines 9a...

Embodiment 2

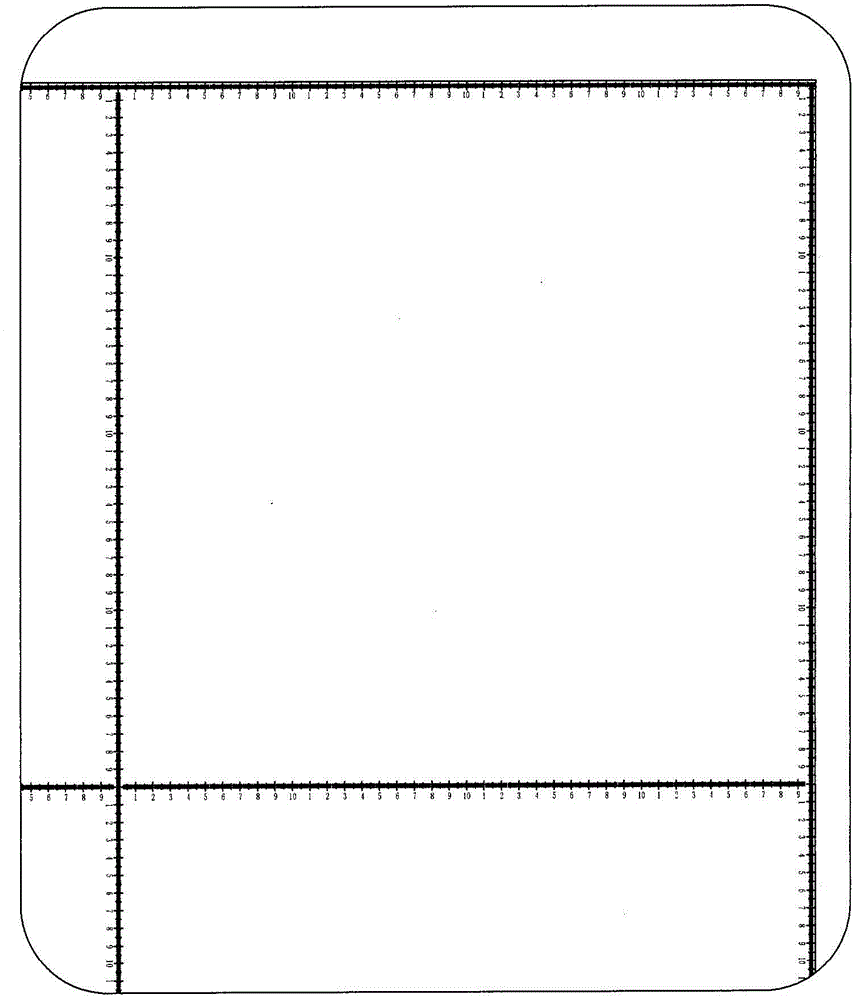

[0024] Embodiment 2: as Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the second embodiment of the gypsum board of the present invention has a gypsum board and a protective paper, and the specification of the gypsum board is: a width of 120 centimeters, a length of 240 centimeters, and a plate-shaped rectangle, which is characterized in that: for The specifications are paper-faced gypsum boards with a width of 120 cm and a length of 240 cm. The protective paper is provided with horizontal scale lines 10, first horizontal scale lines 1, and 120 cm in length parallel to each other from top to bottom. The second horizontal scale line 2 , the third horizontal scale line 3 , the fourth horizontal scale line 4 , the fifth horizontal scale line 5 , and the bottom horizontal scale line 8 . The protective paper is successively provided with parallel longitudinal scale lines 9a, 9b, central vertical scale lines 9c, right vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com