Multi-plate type automatic foldable stage and controlling method of multi-plate type automatic foldable stage

A control method and stage technology, applied in theaters and other directions, can solve the problems of rigid structure, no disassembly or movement of the stage, etc., and achieve the effect of ensuring coordination, simple operation, and rational use of site resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, through the following detailed description, can understand the present invention more completely and better and easily know wherein many accompanying advantages, but the accompanying drawing described here is used to provide the present invention A further understanding of the invention constitutes a part of the present application, and the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute an improper limitation of the present invention.

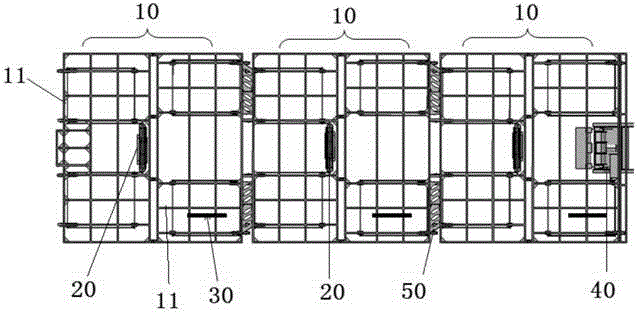

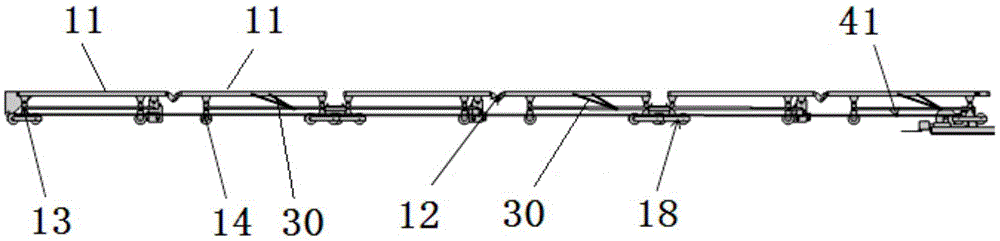

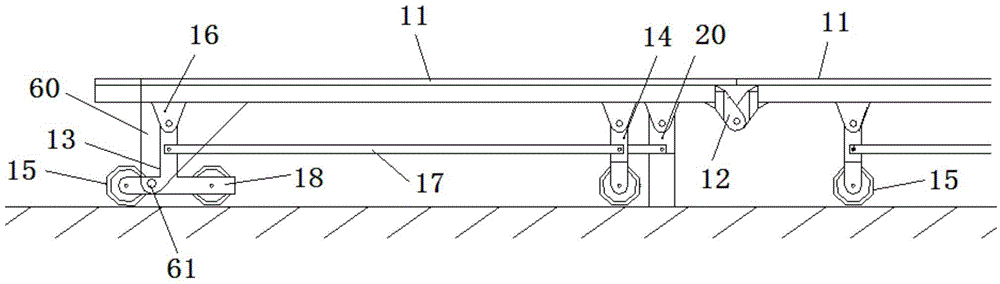

[0029] Such as Figure 1 to Figure 5 As shown, the present invention provides a multi-plate type automatic folding stage, which includes three groups of stages 10, three lifting mechanisms 20, three electric push rod mechanisms 30, a winch 40, a push-pull device and a controller, the first Group stage 10 and third group stage 10 are located at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com