Integrated prefabricated cabin type transformer substation combination structure

A combined structure, prefabricated cabin technology, applied in the field of substations, can solve the problems of not being able to realize combined connection, not suitable for integrated substations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

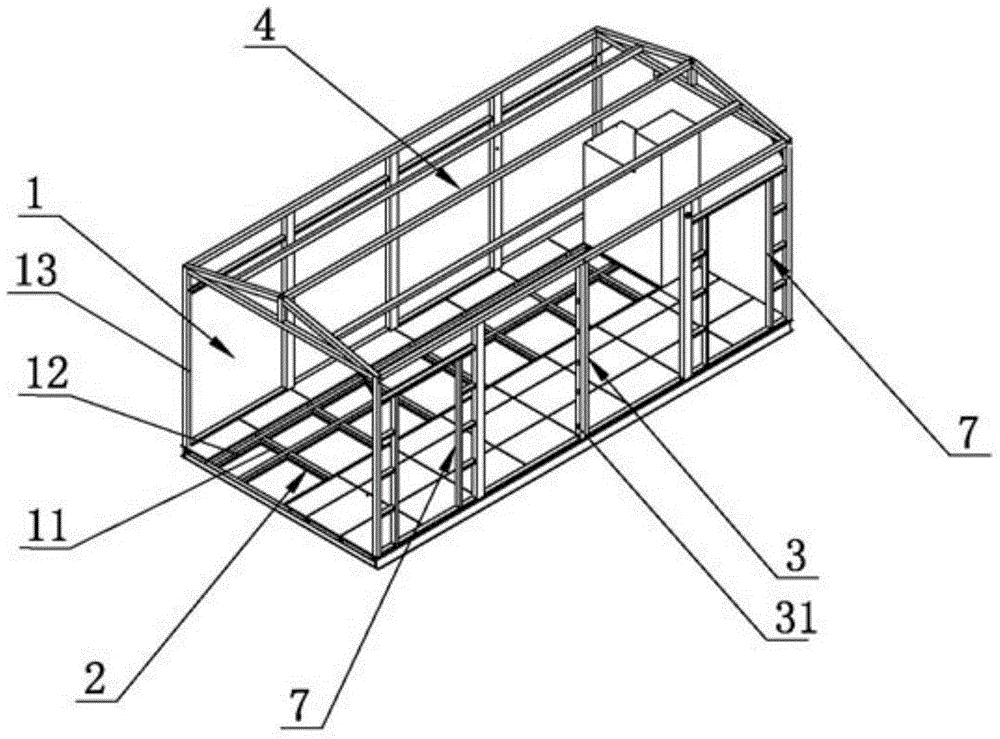

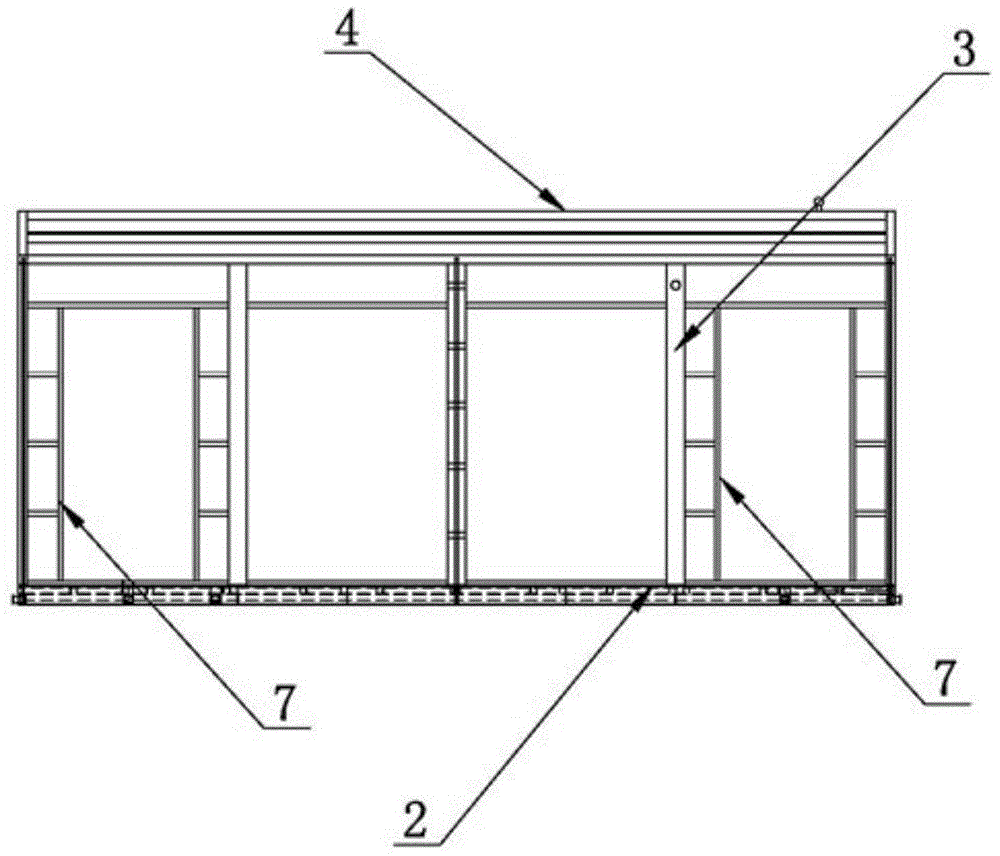

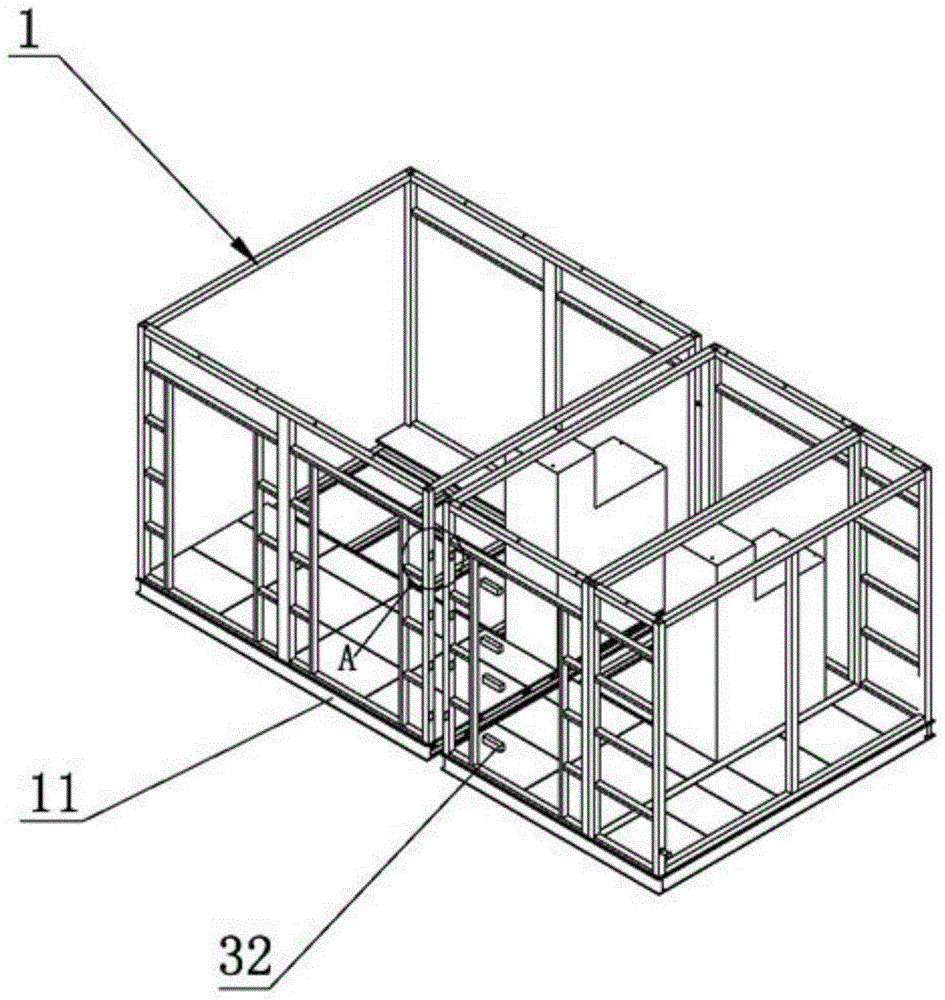

[0026] Such as Figure 1 to Figure 7 As shown, an integrated prefabricated cabin-type substation combined structure of the present invention includes a prefabricated cabin 1, and the prefabricated cabin 1 is formed by connecting several keel profile structural beams with mortise, and the keel profile structural beams include keel profile beams 11. Longitudinal beams 12 of keel profiles and vertical beams 13 of keel profiles, several parallel keel profile beams 11 and several parallel keel profile longitudinal beams 12 are tenon-jointed to form the bottom structure 2 of prefabricated cabin 1, several The vertical beams 13 of the keel profiles are mortised and connected to the bottom structure 2 to form the side wall structure 3 of the prefabricated cabin 1, and several keel profile beams 11 and longitudinal beams 12 of the keel profiles are respectively tenoned and connected to the top of the side wall structure 3 to form the structure of the prefabricated cabin 1. The top stru...

Embodiment 2

[0031] Such as Figure 8 to Figure 9 As shown, the mortise structure of this embodiment includes an I-shaped connecting rod gripping head 5, and the I-shaped connecting rod gripping head 5 includes a connecting rod portion 51, and the two ends of the connecting rod portion 51 are respectively provided with gripping heads. part 52, the gripping heads 52 at the two ends of the connecting rod part 51 are respectively sleeved on the vertical beams 13 of the keel profile of the side wall structure 3 of the adjacent prefabricated cabin 1. The gripping head 5 of the I-shaped connecting rod can be quickly socketed on the vertical beam 13 of the keel profile, so that the adjacent prefabricated cabin 1 can be quickly connected, without the need to provide a tenon joint 31 on the vertical beam 13 of the keel profile, which is convenient for the prefabricated cabin 1 production.

[0032] Specifically, a T-shaped grip 521 is provided on the inner side of the grab head 52 in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com