Non-metallic coiled tubing overshot

A non-metallic, overshot technology, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as non-metallic coiled tubing fishing tools, inability to salvage, and non-metallic coiled tubing broken off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

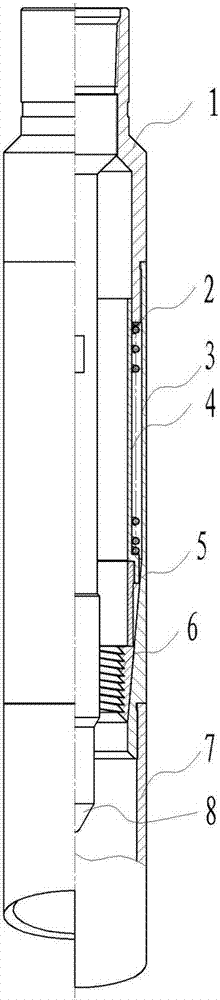

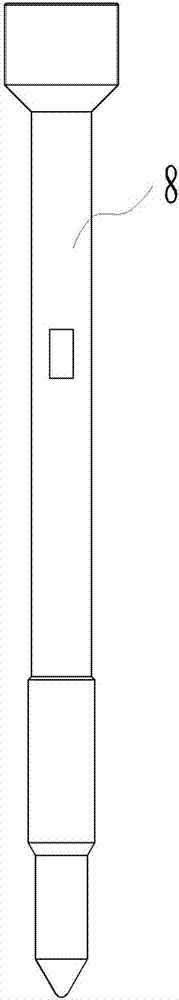

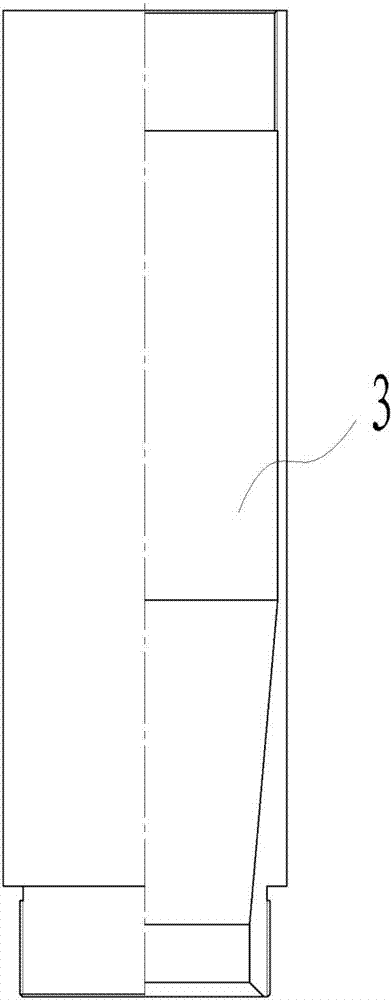

[0010] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it is composed of an upper joint 1, a spring 2, a cylinder 3, a spring seat 4, a positioning sleeve 5, a slip 6, a guide shoe 7 and a core rod 8. The cylindrical body of thread and external thread, the inner wall of the lower end of the cylinder body 3 is a tapered wall whose diameter gradually decreases downward. The cylindrical body of the expansion and contraction port 10, the core rod 8 is a rod-shaped body with a large diameter section, a small diameter section, a middle diameter section, a small diameter section and a conical head from top to bottom, and the upper and lower ends of the cylinder body 3 are respectively It is connected with the upper joint and the guide shoe through threads, the spring 2, the spring seat 4, the positioning sleeve 5, the slips 6 and the core rod 8 are located in the cylinder 3, and the core rod 8 passes through the spring seat 4, the positioning sleeve 5 and the slips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com