Polar Deep Ice Drilling Ice Chip Overshot with Continuous Vibration

An ice debris and deep technology, which is applied in the field of ice debris salvage drilling in the deep ice layer of the polar region, can solve the problems of low efficiency and affecting the progress of drilling ice cores, so as to reduce the number of times and the possibility of accidents in the hole. The effect of reducing the lifting weight of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

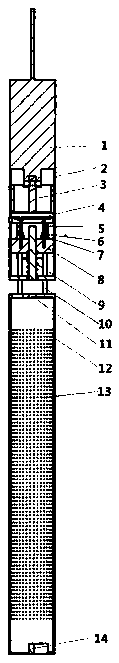

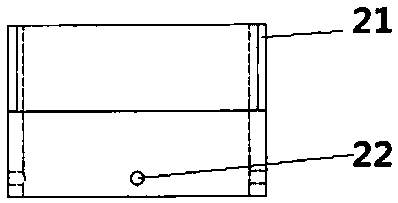

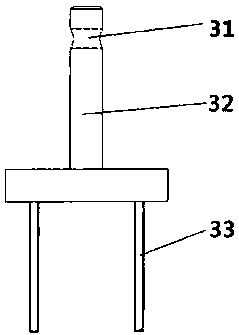

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes an upper slewing mechanism 1, an upper fixed sleeve 2, a rotary disk 3, a lower fixed sleeve 7, a motion conversion plate 8 and an ice chip collection cylinder 12; the upper fixed sleeve 2 has an upper fixed sleeve external thread 21 and an upper Fixed sleeve side positioning hole 22; rotary disc 3 has rotary disc connection shaft hole 31, rotary disc upper shaft 32 and rotary disc drive shaft 33; lower fixed sleeve 7 has lower fixed sleeve side positioning hole 71, bearing step 72, spring positioning shaft 73, the window 74 and the spring positioning lower groove 75; the motion conversion disc 8 has an ice chip tube positioning hole 81, a motion conversion groove 82, a sliding surface 83 in the motion conversion groove and a spring positioning upper groove 84, and the curved surface is raised in the motion conversion groove 82 The sliding surface 83 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com