Constant-pressure and constant-quantity type swab and constant-pressure and constant-quantity swabbing method

A technology of pumping and central pipe, which is applied in the field of liquid drainage and swabbing equipment for oil testing in low-permeability oilfields. It can solve the problems of difficulty in salvaging the wellbore, high cost, and poor effect, and achieve high-efficiency salvage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

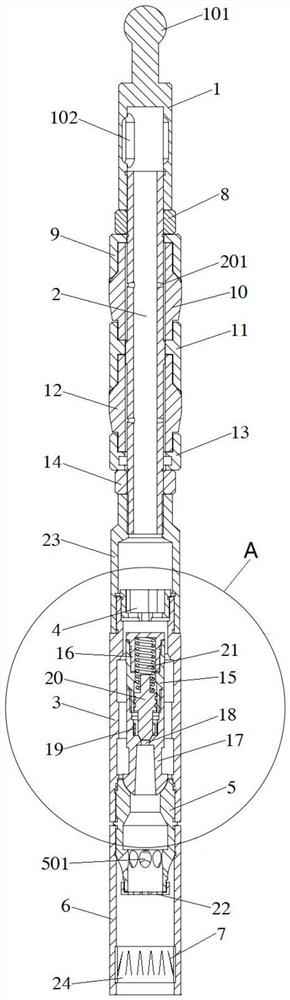

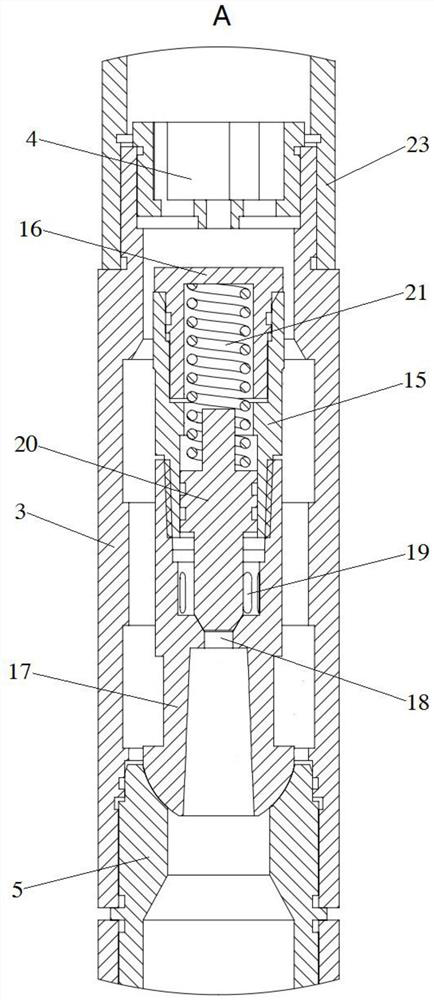

[0031] refer to figure 1 , the embodiment of the present invention proposes a constant pressure and constant volume drawer, including: an upper joint 1, a sealing assembly, a valve body 3, a valve core assembly and an overshot 6; the upper end of the upper joint 1 is a blind end, and a ball is connected Connecting head 101, the inner part of the lower end of upper joint 1 is connected with central pipe 2, and the side wall of upper joint 1 is radially provided with a plurality of first liquid outlet holes 102; There are a plurality of communication holes 201 connected to the inside of the sealing assembly; the valve body 3 is cylindrical, the upper end of the valve body 3 is directly or indirectly connected to the lower end of the central tube 2, and the inner side of the upper end of the valve body 3 is provided with an orifice cover 4 , the inner side of the lower end of the valve body 3 is connected with a ball seat nipple 5, and the ball seat nipple 5 conducts up and down;...

Embodiment 2

[0037] refer to figure 1 , on the basis of Example 1, the sealing assembly includes an upper back cap 8, an upper steel bowl 9, an upper rubber cylinder 10, a middle steel bowl 11, a lower rubber cylinder 12, a lower The steel bowl 13 , the lower back cap 14 , and a plurality of communication holes 201 are respectively connected to the inner sides of the upper rubber cylinder 10 and the lower rubber cylinder 12 .

[0038] When the constant pressure and constant volume pump is lifted up, the lower end of the valve core assembly blocks the upper port of the ball seat nipple 5 under its own gravity, and the liquid on the upper part of the constant pressure and constant volume pump will enter the upper port through a plurality of first liquid outlet holes 102. In the joint 1 and the central pipe 2, after entering the inner side of the upper rubber cylinder 10 and the lower rubber cylinder 12 through a plurality of communication holes 201, the hydraulic pressure will make the upper...

Embodiment 3

[0040] refer to figure 1 and figure 2 , on the basis of Embodiment 3, the outer side of the lower port of the lower spool 17 is provided with an outer arc surface, and the inner side of the upper port of the ball seat nipple 5 is provided with an inner arc surface, and the outer arc surface and the inner arc faces match.

[0041] Because there is an annular gap between the valve core assembly and the inner side wall of the valve body 3, the valve core assembly will be in an inclined state in the valve body 3, and the lower valve core 17 at the lower end of the valve core assembly passes through the outer arc surface and the ball seat. The inner arc surface of the upper port of the pup joint 5 is kept in sealing contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com