overshot

An overshot and outer sleeve technology, applied in the field of tools and overshots, can solve the problems of restricting the progress of the project and the time limit of construction, the force fracture of the cable, the complication of accidents, etc. The effect of salvage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

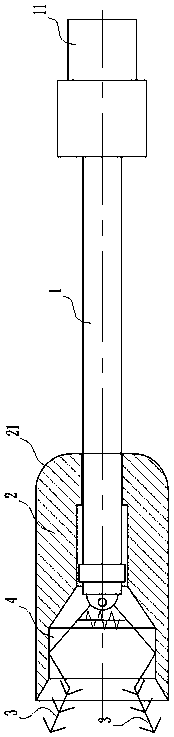

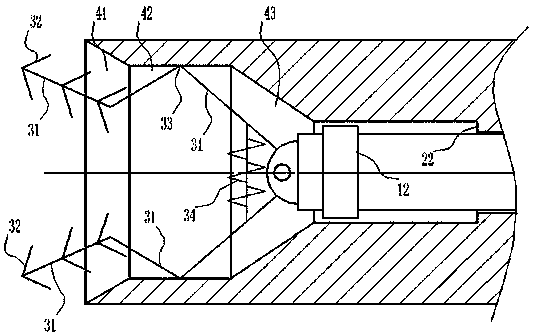

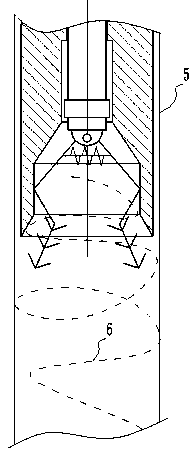

[0036] The overshot of the present invention has an overall structure such as figure 1 As shown, it includes a connecting rod 1, the connecting rod 1 is sleeved with a bidirectionally slidable outer sleeve 2, and the end of the connecting rod 1 is provided with a group of radially openable and closeable pawls 3. When the outer sleeve 2 is away from When the pawl 3 moves in the direction, the pawl 3 can be disengaged from the inner cavity 4 of the outer sleeve 2 and open, and when the outer sleeve 2 moves in the direction of the pawl 3, the pawl 3 can be closed and stored in the outer sleeve 2 in the lumen 4. Its opening and closing process is as Figure 4 , Figure 5 , Image 6 shown.

[0037] The outer sleeve 2 of this embodiment adopts a thick-walled design and has a relatively large self-weight. The overshot can conveniently and quickly salvage the falling objects of oil and gas drilling and exploitation. Compared with the existing conventional overshot, the overshot o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com