Lubricating compensation compressor

A technology of compressor and compression cylinder, applied in the field of gas compression equipment, can solve the problems of low reliability and strong subjective dependence, achieve the effects of high accuracy, improve gas compression efficiency, and reduce friction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

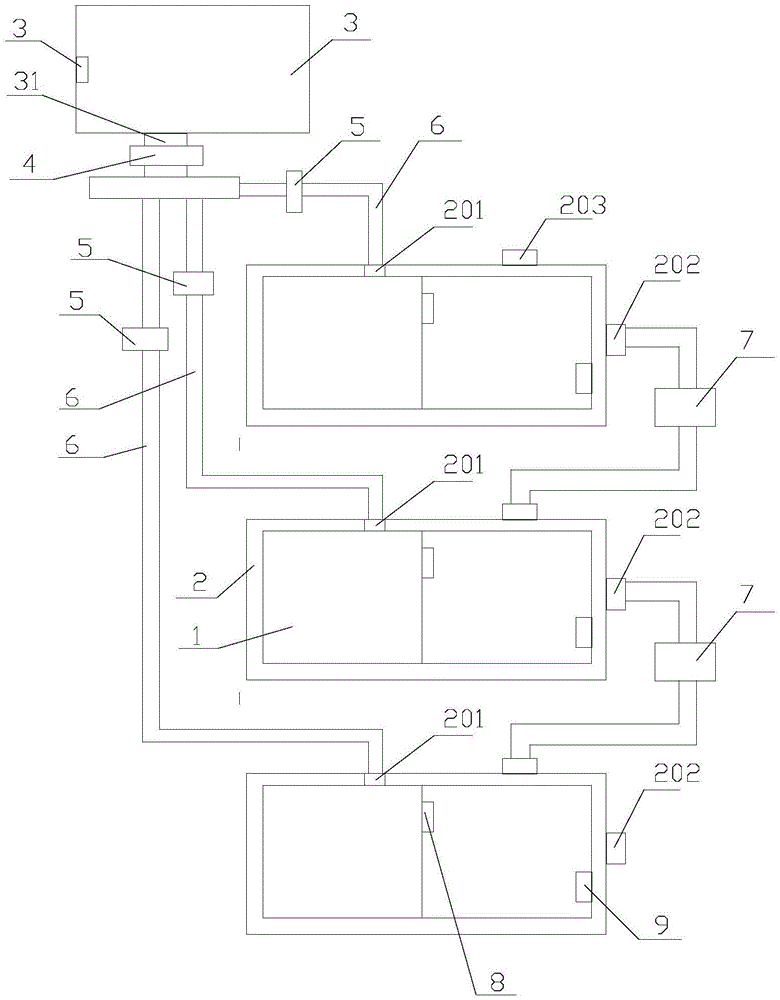

[0020] refer to figure 1 , a kind of lubrication compensating compressor that the present invention proposes, comprises: a plurality of pistons 1, a plurality of compression cylinders 2, oil storage tank 3, oil outlet valve 4, a plurality of refueling valves 5, a plurality of oil delivery pipes 6, liquid level Sensor 10, display device, alarm device and control module.

[0021] The compression cylinder 2 is provided with an air inlet 201 and an air outlet 202, and a plurality of compression cylinders 2 are arranged in sequence, and the air outlet 202 of the previous compression cylinder 2 is connected to the air inlet 201 of the next compression cylinder 2, and any two adjacent A one-way valve 7 is arranged between the compression cylinders 2, specifically a one-way pressure valve.

[0022] A piston 1 is movably installed inside each compression cylinder 2, that is, the number of piston 1 and compression cylinder 2 is equal, and the piston 1 is movably installed inside the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com