Anti-rust pipe seat structure and water heater adopting structure

A water heater and pipe seat technology, which is applied in the field of anti-rust pipe seat structure, can solve the problems such as the fit of the external pipe lining, the inability to extend to the threaded section, and the outflow of rust water, so as to solve the leakage of rust water and prevent the outflow of rust water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

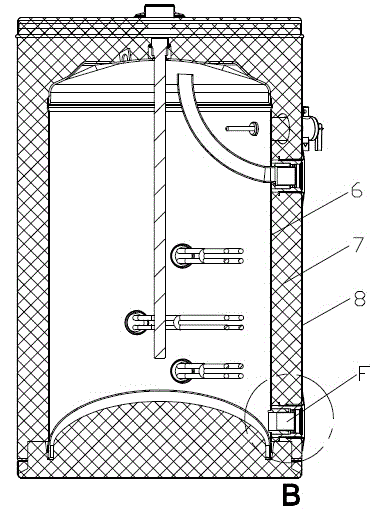

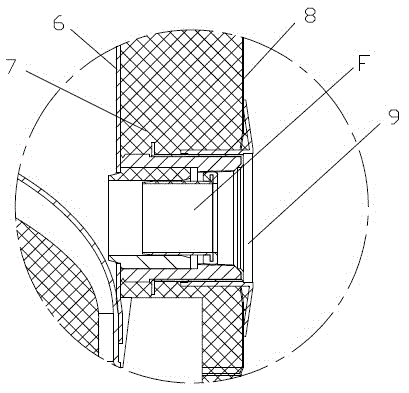

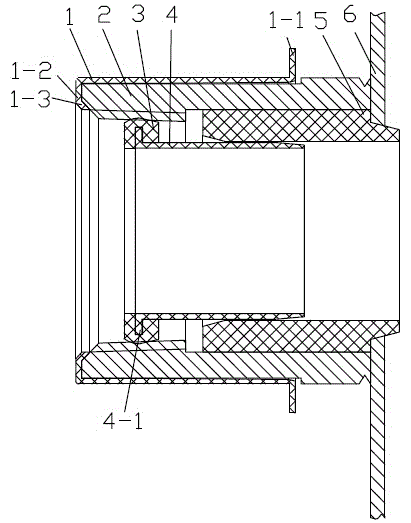

[0020] The present embodiment adopts the water heater of anti-rust pipe base structure such as figure 1 As shown, it includes a water heater inner tank surrounded by cylinder plates 6, an outer shell 8, and a foam insulation layer 7 filled between the inner tank and the outer shell. An anti-rust pipe seat structure F is installed at the opening where the liner communicates with the external pipeline. The outer end of the anti-rust pipe seat structure is substantially flush with the shell 8, and the periphery is embedded with a decorative ring 9 with an outer flanging. The specific structure is as follows figure 2 , 3 As shown, it includes an anti-rust material liner 5 embedded and fixed at the opening of the cylinder plate 6 through the inner tapered end. The outer end of the outer tight sleeve of the liner pipe 5 has a pipe seat 2 with a reduced diameter connected to the internal thread. The shrinking section at the outer end of the pipe base 2 is covered with a plastic s...

Embodiment 2

[0024] In this embodiment, the structure of the water heater using the antirust pipe base structure is the same as that in Embodiment 1, the difference is that the structure of the antirust pipe base is as follows: Figure 4 Shown, the water heater such as figure 1 As shown, an axial spring 11 is installed between the outer end surface of the liner 5 and the inner end surface of the outer flange of the conduit 4 . Therefore, even if the outer connecting pipe with longer threaded section is replaced with one with shorter threaded section, that is, the thread length changes within a certain range, under the action of the axial spring, the elastic threaded sealing sleeve 3 and the end surface of the outer connecting pipe 10 are always in close contact. Closed, and pressed so that the protrusion of the outer circle is fully embedded in the internal thread groove of the pipe seat 2, so as to maintain the sealing effect of effectively blocking the leakage of rust water.

[0025] Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com