A kind of metering oil pipe for petrochemical industry and preparation method thereof

A petrochemical and oil pipe technology, which is applied in the field of petrochemical metering oil pipes and its preparation, can solve the problems of oil products that are easily polluted, fuel oil is easy to leak, and pollute the environment. It achieves excellent environmental performance and antistatic performance, avoids pollution, and realizes The effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

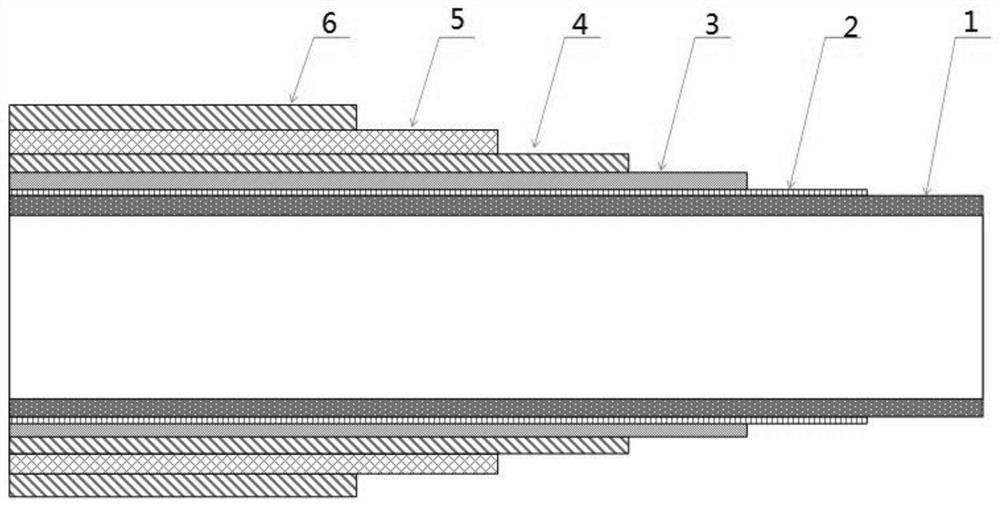

[0061] 1. This embodiment provides a metering oil pipe for petrochemical industry, which includes the following six-layer structure from inside to outside:

[0062] Low-permeability barrier layer 1, with a thickness of 0.25 mm, is prepared from polyimide (PI), polyphenylene sulfide (PPS) and polyphenylene oxide (PPO) at a mass ratio of 1:2.5:5.

[0063] Adhesive layer 2, with a thickness of 0.05 mm, is a maleic anhydride graft-modified polyethylene (MAH-g-PE) adhesive layer.

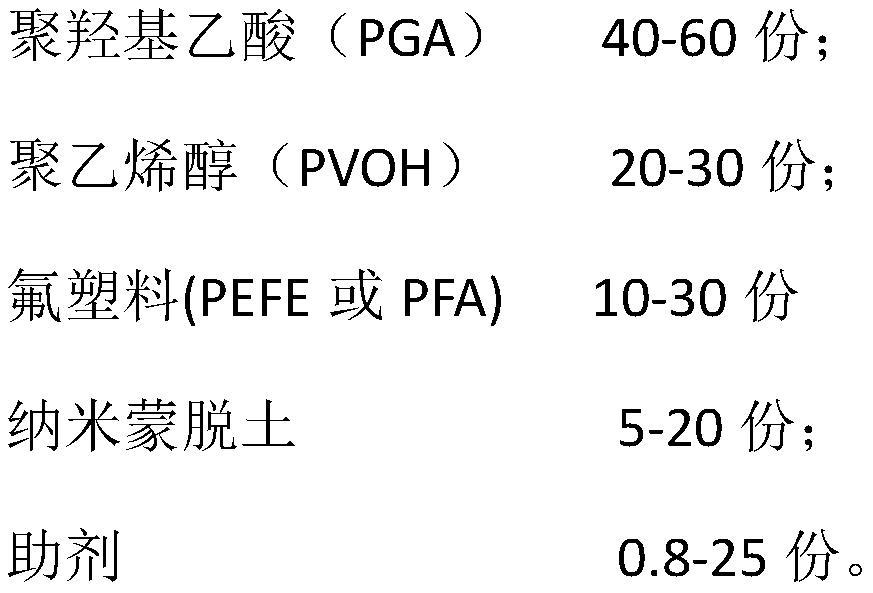

[0064] Reinforced barrier layer 3, with a thickness of 0.2 mm, is prepared from the following ingredients in parts by mass:

[0065]

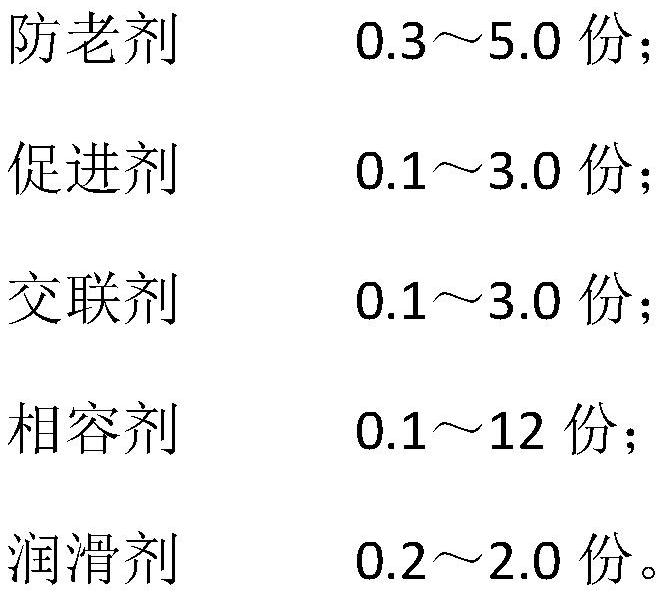

[0066] Other additives are:

[0067]

[0068] The first antistatic plastic layer 4 has a thickness of 1.5 mm and is prepared from the following ingredients in parts by mass:

[0069] 3 parts of antistatic agent;

[0070] 32 parts of thermoplastic elastomer (TPE);

[0071] 65 parts of general rubber material;

[0072] 0.5 parts of coupling agent;

[0073] 0.5 p...

Embodiment 2

[0093] 1. This embodiment provides a metering oil pipe for petrochemical industry, which includes the following six-layer structure from inside to outside:

[0094] The low-permeability barrier layer 1 has a thickness of 0.33 mm and is prepared from the following components in parts by mass: PI:PPS:PPO=1:3:4.5 mass ratio.

[0095] Adhesive layer 2, with a thickness of 0.05 mm, is a maleic anhydride graft-modified polyethylene (MAH-g-PE) adhesive layer.

[0096] Reinforced barrier layer 3, with a thickness of 0.15 mm, is prepared from the following ingredients in parts by mass:

[0097]

[0098]

[0099] Other additives are:

[0100]

[0101] The first antistatic plastic layer 4 has a thickness of 1.0 mm, and is prepared from the following ingredients in parts by mass:

[0102] 3 parts of antistatic agent;

[0103] 45 parts of thermoplastic elastomer (TPE);

[0104] 52 parts of general rubber material;

[0105] 0.5 parts of coupling agent;

[0106] 0.5 parts of com...

Embodiment 3

[0126] 1. This embodiment provides a metering oil pipe for petrochemical industry, which includes the following six-layer structure from inside to outside:

[0127] The low-permeability barrier layer 1 has a thickness of 0.40mm and is prepared from the following components in parts by mass: PI:PPS:PPO=1:3:5.5 mass ratio.

[0128] Adhesive layer 2, with a thickness of 0.05 mm, is a maleic anhydride graft-modified polyethylene (MAH-g-PE) adhesive layer.

[0129] Reinforced barrier layer 3, with a thickness of 0.08 mm, is prepared from the following ingredients in parts by mass:

[0130]

[0131] Other additives are:

[0132] 0.8 part of anti-aging agent;

[0133] Accelerator 0.6 parts;

[0134] 0.5 parts of crosslinking agent;

[0135] 0.3 parts of lubricant.

[0136] The first antistatic plastic layer 4 has a thickness of 1.6mm, and is prepared from the following ingredients in parts by mass:

[0137] 5 parts of antistatic agent;

[0138] Thermoplastic elastomer (TPE)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com