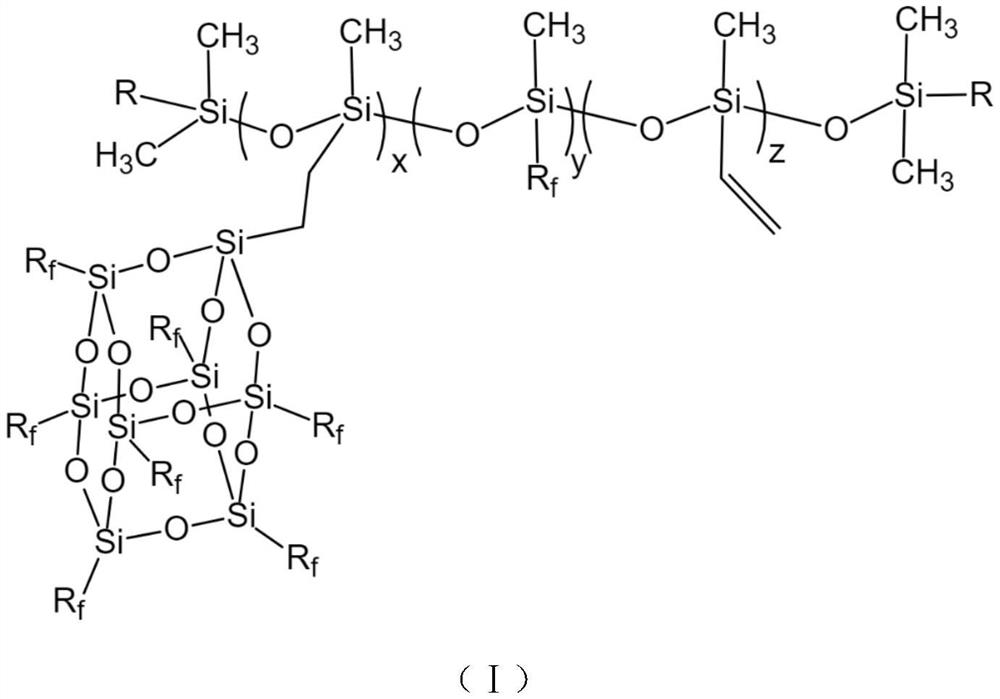

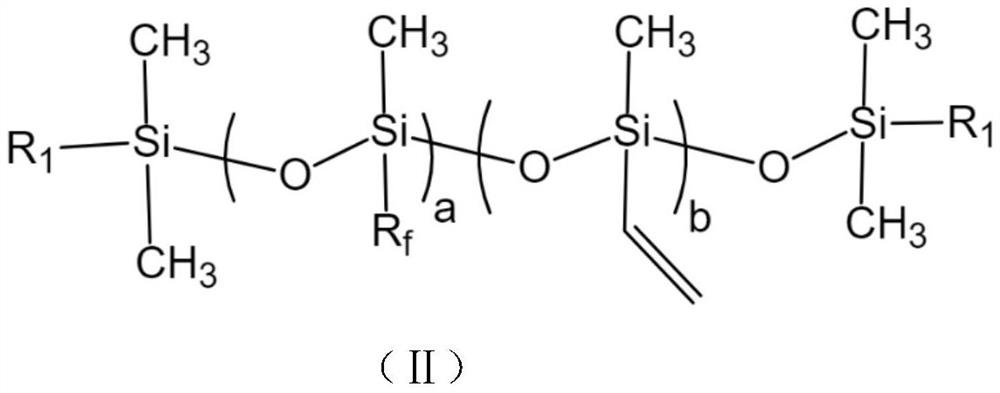

A kind of fluorosilicone rubber composition and preparation method

A technology of fluorosilicone rubber and composition, applied in the field of fluorosilicone rubber composition and preparation, can solve the problems of affecting hydrocarbon solvent resistance and oil resistance, serious roller sticking, affecting production efficiency and safety, etc. performance and high temperature resistance, improve mechanical properties, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

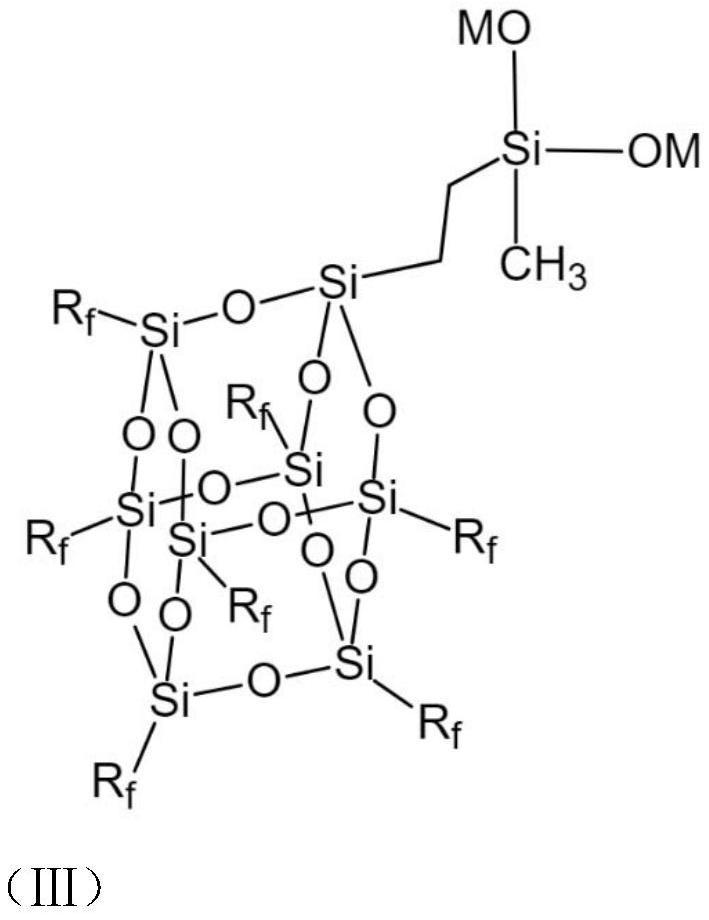

[0043] Preparation of cage polysilsesquioxane dialkoxysilanes

[0044] Preparation of Cage Polysilsesquioxane Methyldimethoxysilane

[0045] Add 10 parts of hepta(3,3,3-trifluoropropyl)vinyl cage polysilsesquioxane and 2 parts of methyldimethoxysilane into 20 parts of toluene, heat up to 90°C under stirring, and pass Into nitrogen protection, add Karstedt catalyst (according to Pt calculation, accounting for 5ppm of the total mass of reaction raw materials), continue to heat up to 120 ° C, react for 3 hours, and distill toluene and unreacted methyldimethoxysilane under reduced pressure to obtain cage Type polysilsesquioxane methyldimethoxysilane.

[0046] FT-IR analysis compares seven (3,3,3-trifluoropropyl) vinyl cage polysilsesquioxane and product cage polysilsesquioxane methyldimethoxysilane, at 1604cm -1 There is no absorption peak nearby, indicating that the vinyl reaction is relatively complete.

[0047] Preparation of Cage Polysilsesquioxane Methyldiethoxysilane

[...

preparation approach 3

[0052] Preparation scheme three: Accurately weigh each raw material, D 3 F and D 4 Vi Pre-dehydration treatment, 10 parts of cage polysilsesquioxane methyldimethoxysilane, 9 parts of D 3 F and 0.08 parts D 4 Vi Mix evenly, add alkali gel (calculated as sodium hydroxide, accounting for 0.01% of the weight of all reaction raw materials), stir and mix evenly, fill the whole reaction process with nitrogen protection, heat up to 140 ° C for 20 minutes, add the remaining 29 parts of D 3 F , continue to heat up to 150°C until the stirring bar cannot rotate, keep the temperature at 145-150°C for 1 hour, cool down, and release the glue to obtain fluorine-containing cage polysilsesquioxane modified fluorosilicone raw rubber 2-3 (abbreviated as fluorine Silicone Gum II-3).

preparation approach 4

[0053] Preparation scheme four: Accurately weigh each raw material, D 3 F and D 4 Vi Pre-dehydration treatment, 10 parts of cage polysilsesquioxane methyldiethoxysilane, 12 parts of D 3 F and 0.06 parts D 4 Vi Mix evenly, add alkali gel (calculated as sodium hydroxide, accounting for 0.01% of the weight of all reaction raw materials), stir and mix evenly, fill the whole reaction process with nitrogen protection, heat up to 140 ° C for 30 minutes, add the remaining 7 parts of D 3 F , continue to raise the temperature to 150°C until the stirring rod cannot rotate, keep the temperature at 145-150°C for 1 hour, cool down, and produce glue to obtain fluorine-containing cage polysilsesquioxane modified fluorosilicone raw rubber 2-4 (abbreviated as fluorine Silica gel II-4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com