Method for measuring object density based on air pressure process

A technology of gas pressure and objects, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problem of scarcity of cotton fiber material density measurement methods, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

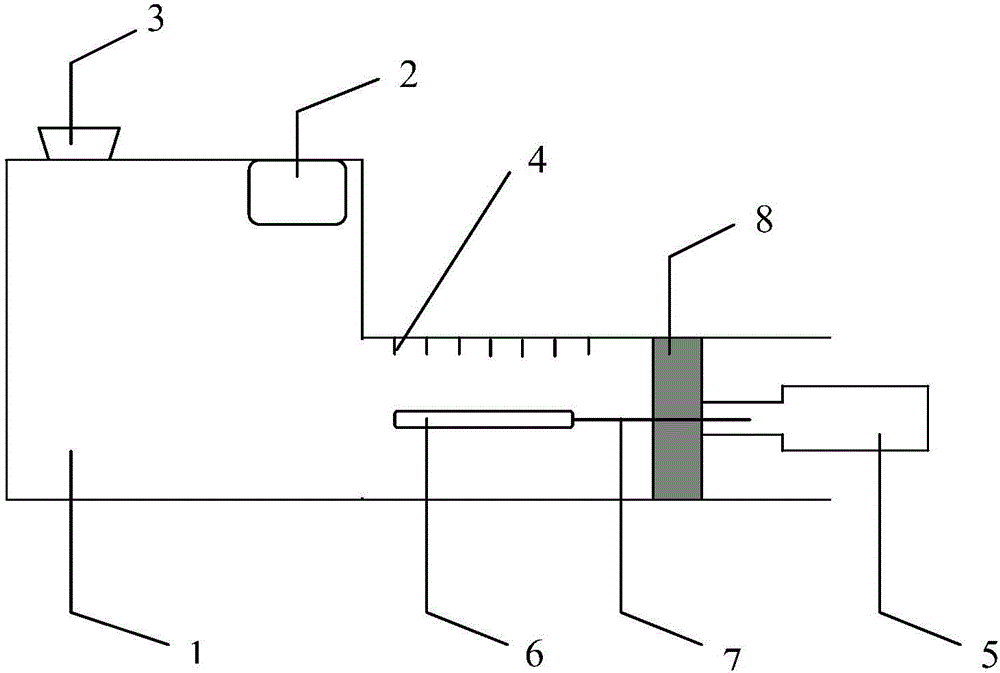

[0032] A method for measuring the density of an object based on the gas pressure method, the method adopts a device capable of measuring the gas pressure coefficient to measure the density of the object,

[0033] The device capable of measuring the gas pressure coefficient includes a sealed container 1 with a sealed cover 3 and a volume scale 4, a thermometer 2, a load cell 5 and a pressure sensor 6, wherein a piston 8 is arranged on the sealed container 1, and the piston 8 will The container is sealed, the thermometer 2 is arranged inside the sealed container 1, the pressure sensor 6 is arranged inside the sealed container 1, and is connected to the dynamometer 5 arranged outside the sealed container 1 through the hose 7, and the dynamometer 5 is connected to the piston 8;

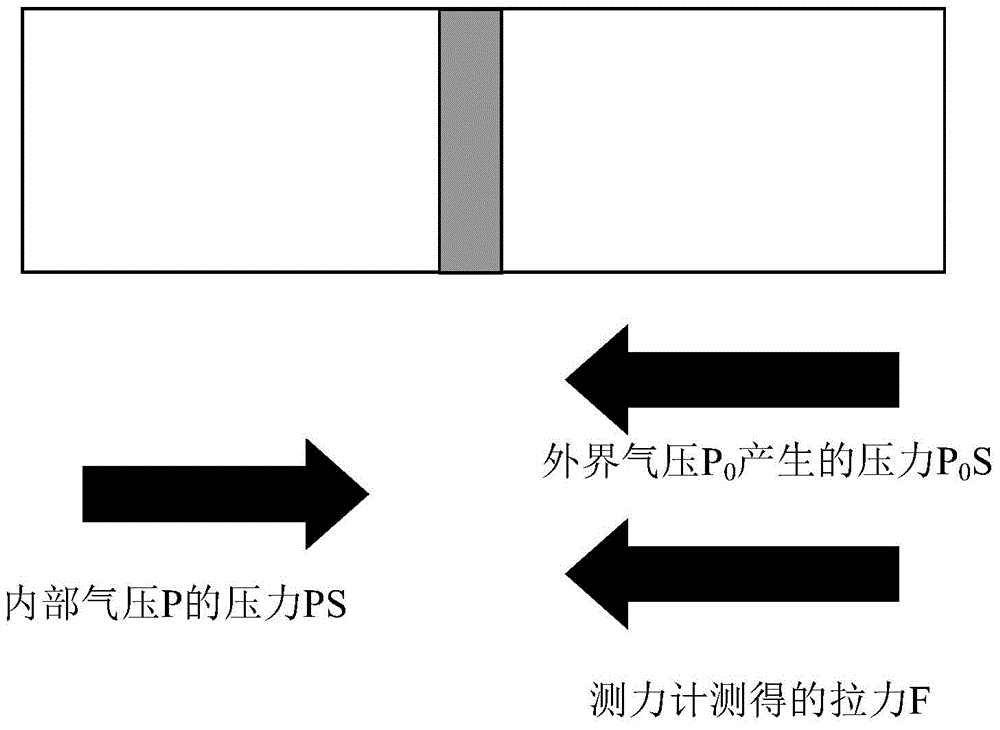

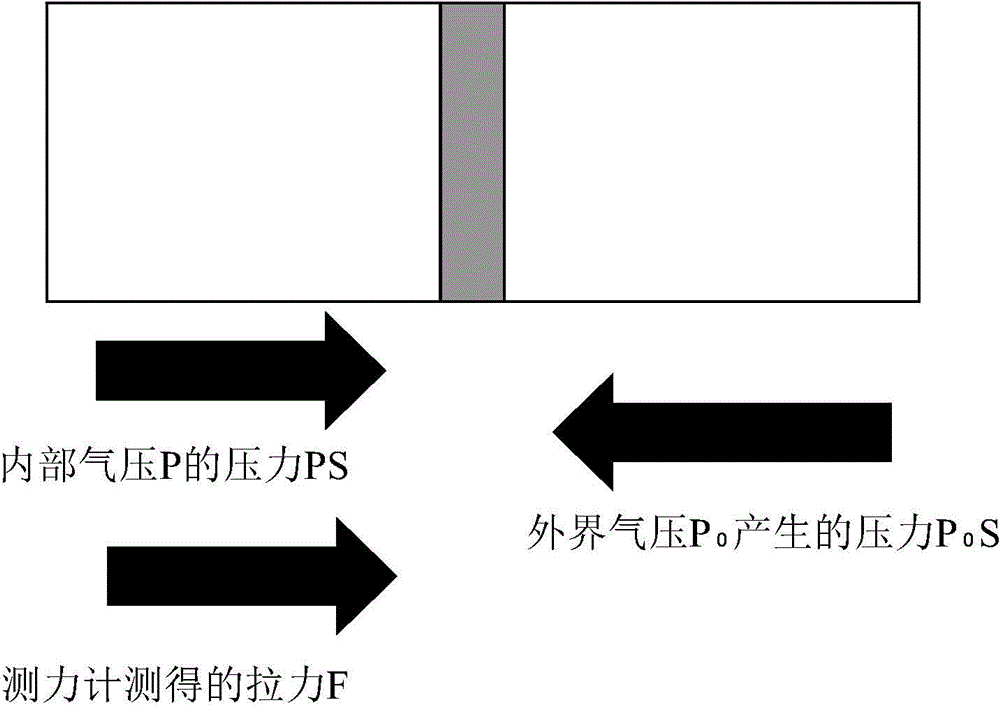

[0034] The method for measuring the density of an object using the device capable of measuring the gas pressure coefficient comprises the following steps:

[0035] (1) Open the sealing cover 3, pull the p...

Embodiment 2

[0058] Adopt the method of embodiment 1, measure the density of plastic block and stone block.

[0059] Table 1 shows the density of plastic blocks and stones measured by the traditional object density measurement method - hydrostatic measurement method.

[0060] Table 2 shows the densities of the plastic blocks and stones measured by the method described in Example 1, wherein the plastic blocks and stones are the plastic blocks and stones used for measurement in Table 1. According to the corresponding volume of the plastic block or stone when the volume change of the syringe after adding the plastic block or stone is 10ml, 20ml, 30ml respectively, the density of the plastic block or stone is calculated.

[0061] Table 1. The data of the measured object measured by the hydrostatic measurement method (traditional method)

[0062]

[0063] Table 2. The plastic block and stone block density that the inventive method measures

[0064]

[0065]

[0066] The results in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com