Perlite insulation board production process

A technology of perlite insulation board and production process, applied in the direction of manufacturing tools, mixers, ceramic molding machines, etc. Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

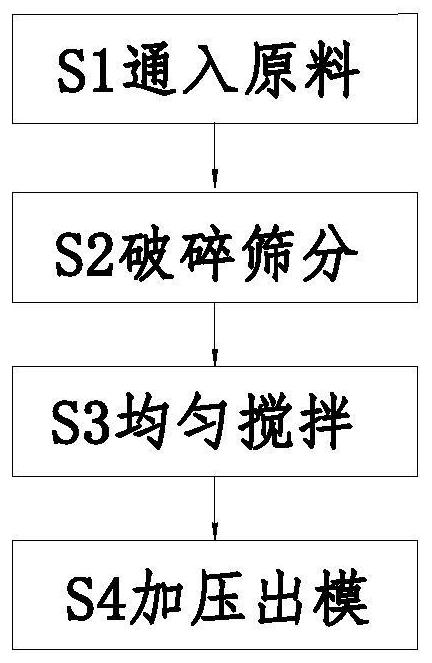

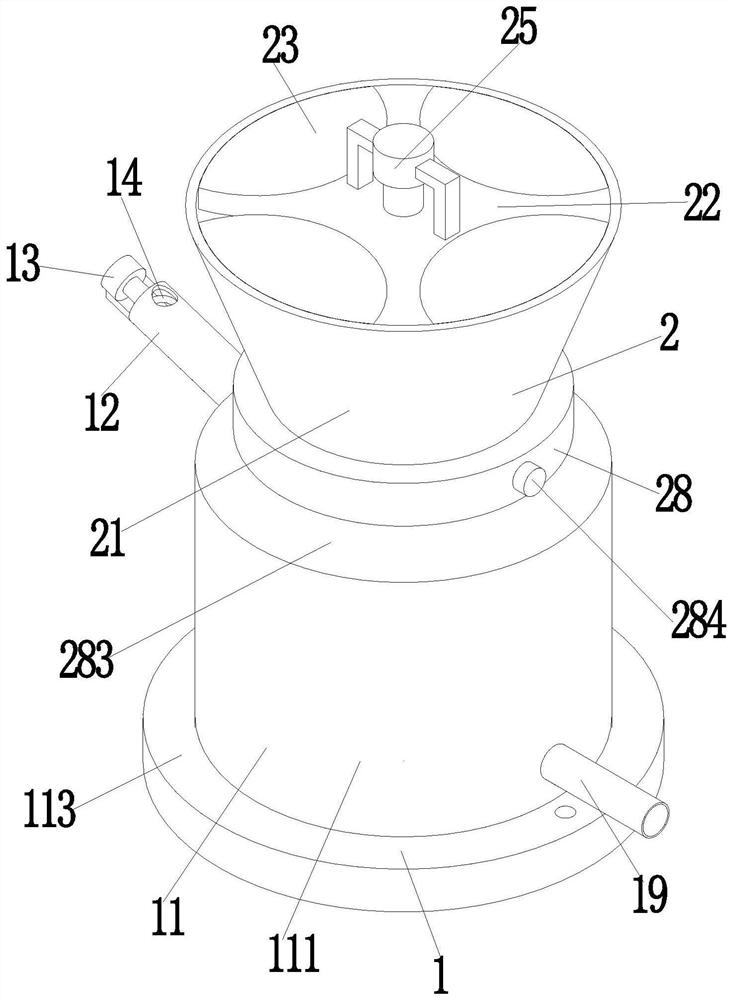

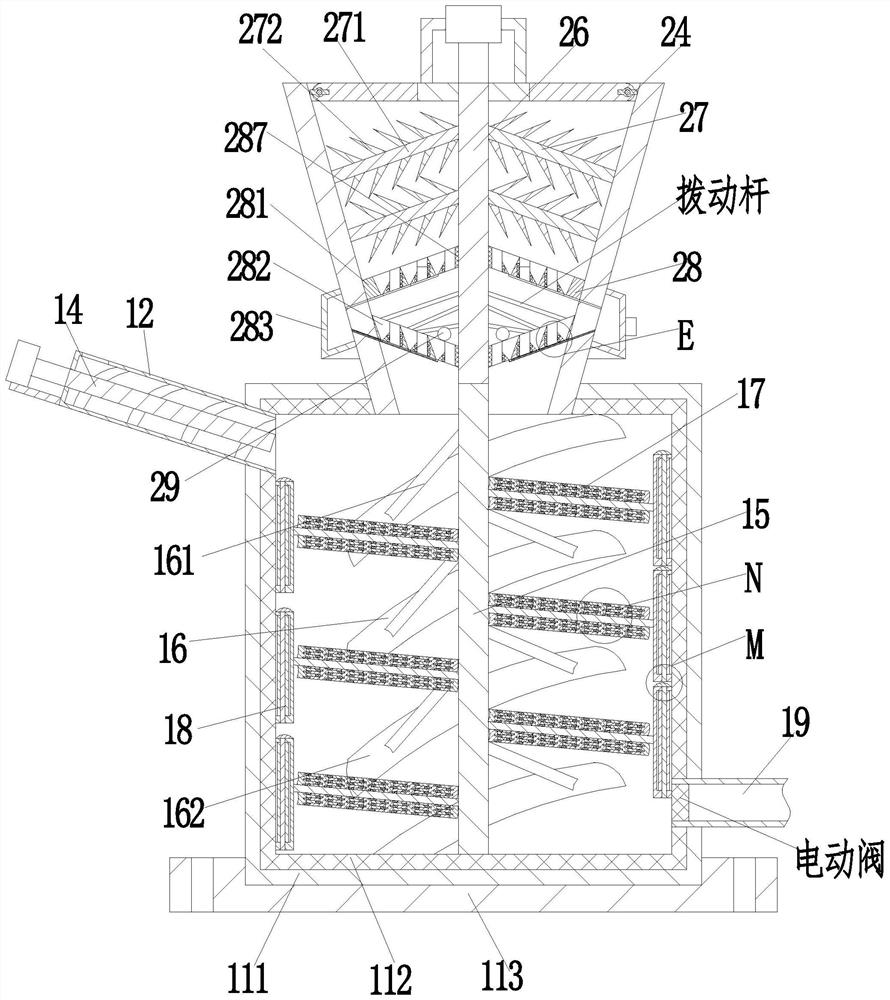

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0038] A production process for perlite insulation boards, which uses a perlite insulation board production equipment, the perlite insulation board production equipment includes a stirring device 1 and a material selection device 2, the perlite insulation board production equipment is used to process the perlite insulation board The specific method of production is as follows:

[0039] S1. Feed raw materials: pass the raw materials into the conical cylinder 21 through the feed plate 22;

[0040] S2. Crushing and screening: the motor 225 drives the rotating column 26 to tie the U shield, thereby driving the crushing frame 27 to crush the raw materials, and the crushed raw material particles are screened through the screening frame 28 and the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com