Dual-motor starting gear speed-reducing wheel type energy storage device

An energy storage device and gear deceleration technology, which can be used in electromechanical devices, electric components, control mechanical energy, etc., and can solve the problem of insignificant energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

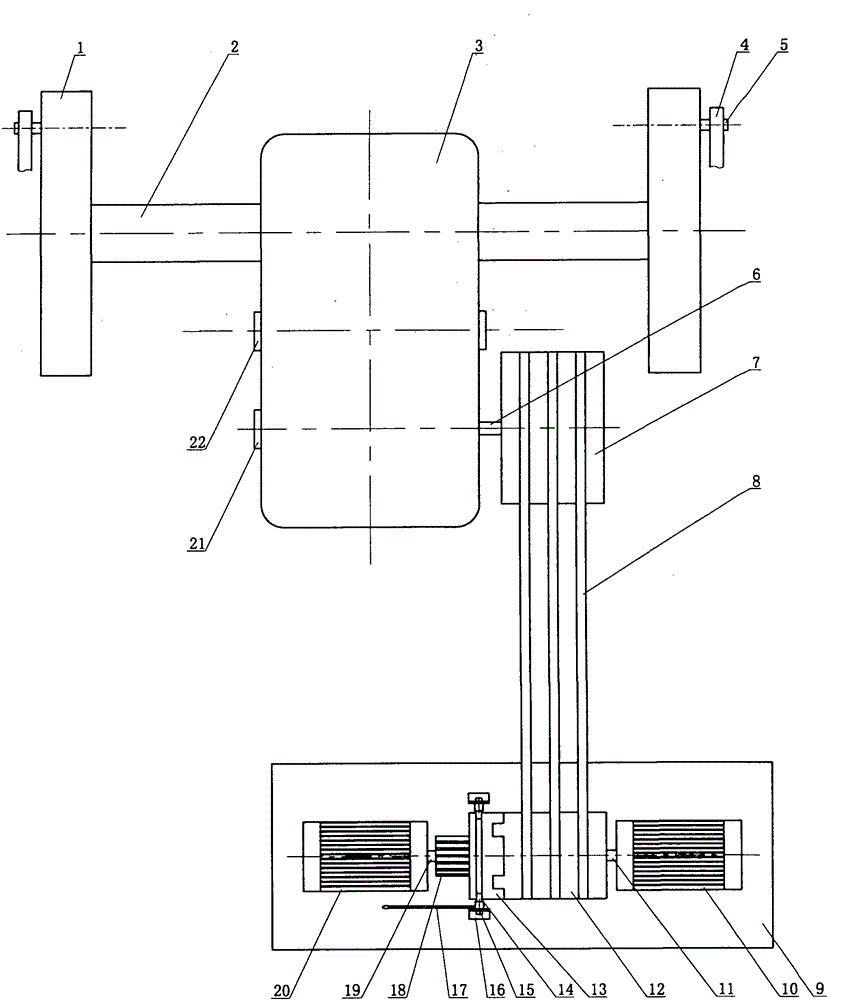

[0013] Such as figure 1 The present embodiment shown includes an output shaft wheel 1, an output shaft 2, a gear reduction box 3, a connecting rod 4, a connecting rod shaft 5, an input shaft 6, an input shaft pulley 7, a belt 8, a motor base 9, and a working motor 10 , working motor shaft 11, motor pulley 12, tooth insert 13, shift fork 14, shift fork shaft 15, shift fork base 16, pull rod 17, spline shaft 18, start motor shaft 19, start motor 20, input shaft bearing cover 21 And intermediate shaft bearing cover 22 etc. The output shaft wheel 1 is installed on the output shaft 2 of the gear reduction box 3, the connecting rod shaft 5 connects the connecting rod 4 and the output shaft wheel 1, and the input shaft pulley 7 is installed on the input shaft 6 of the gear reduction box 3. Working motor 10 is installed on the motor base 9, motor pulley 12 is installed on the working motor shaft 11, and the outside of motor pulley 12 has teeth, so that with tooth socket 13 interlocki...

Embodiment 2

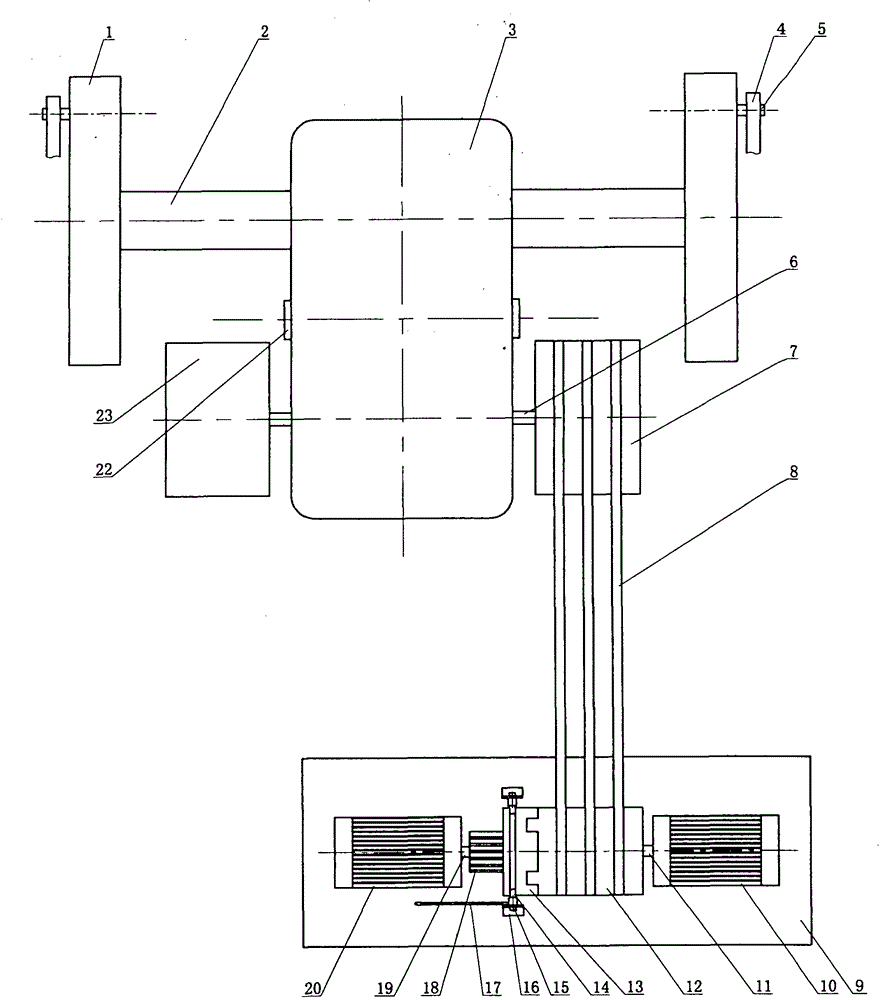

[0015] Such as figure 2 The present embodiment shown includes an output shaft wheel 1, an output shaft 2, a gear reduction box 3, a connecting rod 4, a connecting rod shaft 5, an input shaft 6, an input shaft pulley 7, a belt 8, a motor base 9, and a working motor 10 , working motor shaft 11, motor pulley 12, tooth insert 13, shift fork 14, shift fork shaft 15, shift fork base 16, pull rod 17, spline shaft 18, start motor shaft 19, start motor 20, intermediate shaft bearing cover 22 And input shaft wheel 23 etc. An output shaft wheel 1 is installed on the output shaft 2 of the gear reduction box 3, and the connecting rod shaft 5 connects the connecting rod 4 and the output shaft wheel 1 together. An input shaft pulley 7 is installed at one end of the input shaft 6 of the gear reduction box 3. One end is equipped with input shaft wheel 23. Working motor 10 is installed on the motor base 9, motor pulley 12 is installed on the working motor shaft 11, and the outside of motor p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com