Cooling device, particularly for battery modules, and vehicle comprising such a cooling device

A cooling device and battery technology, which is applied in battery/fuel cell control devices, battery/battery traction, electric vehicles, etc., can solve problems such as unfavorable heat transfer and extrusion of assembly boards and batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

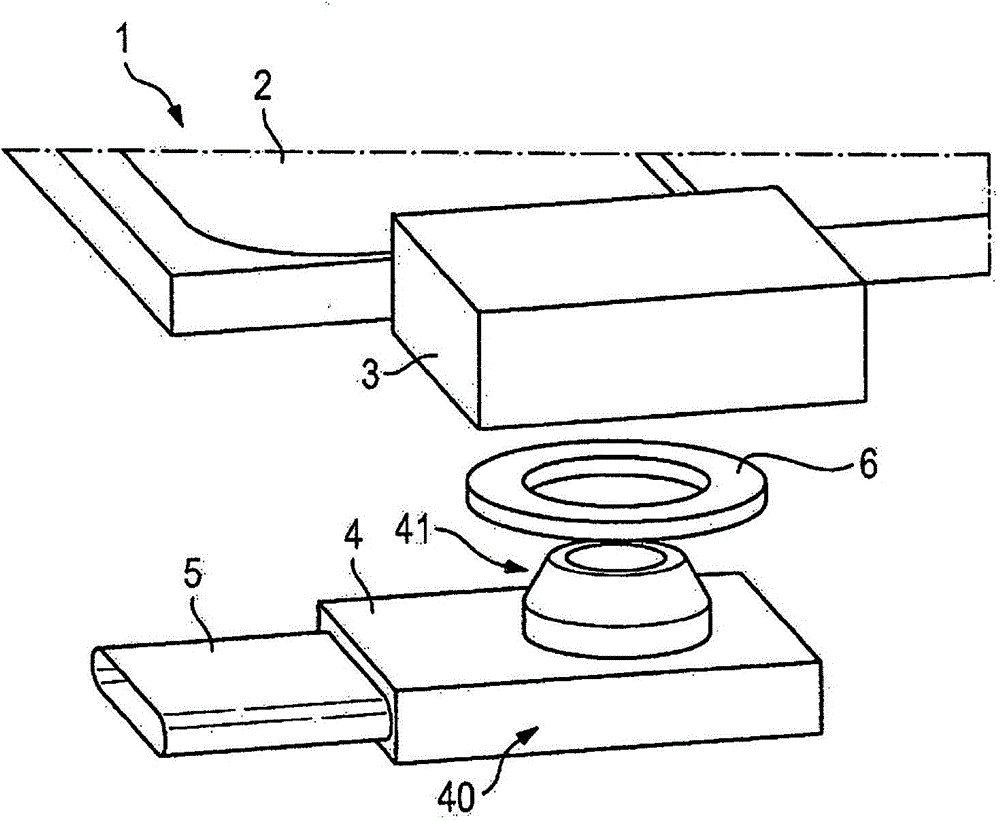

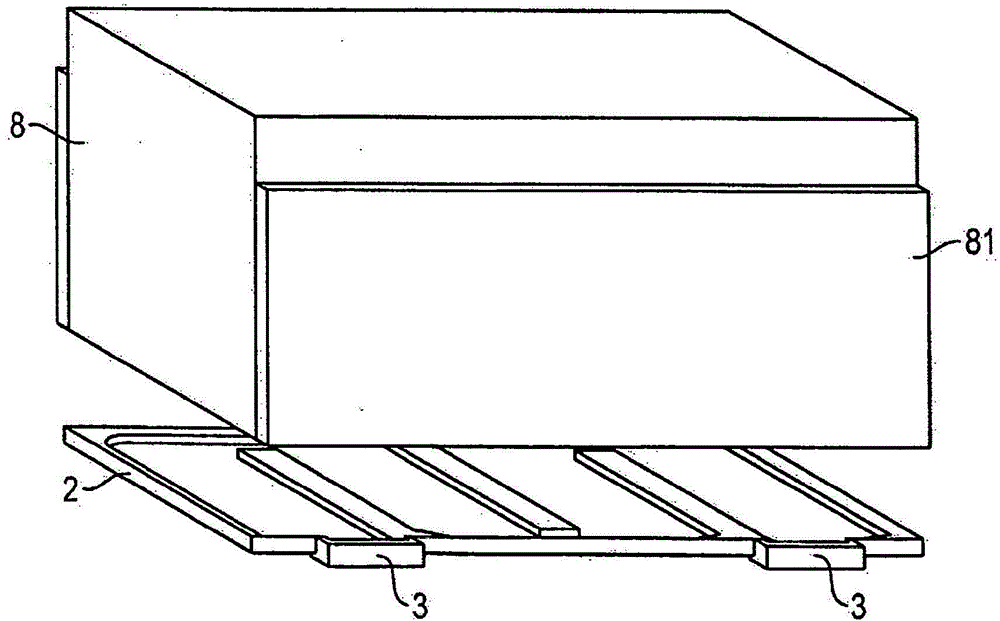

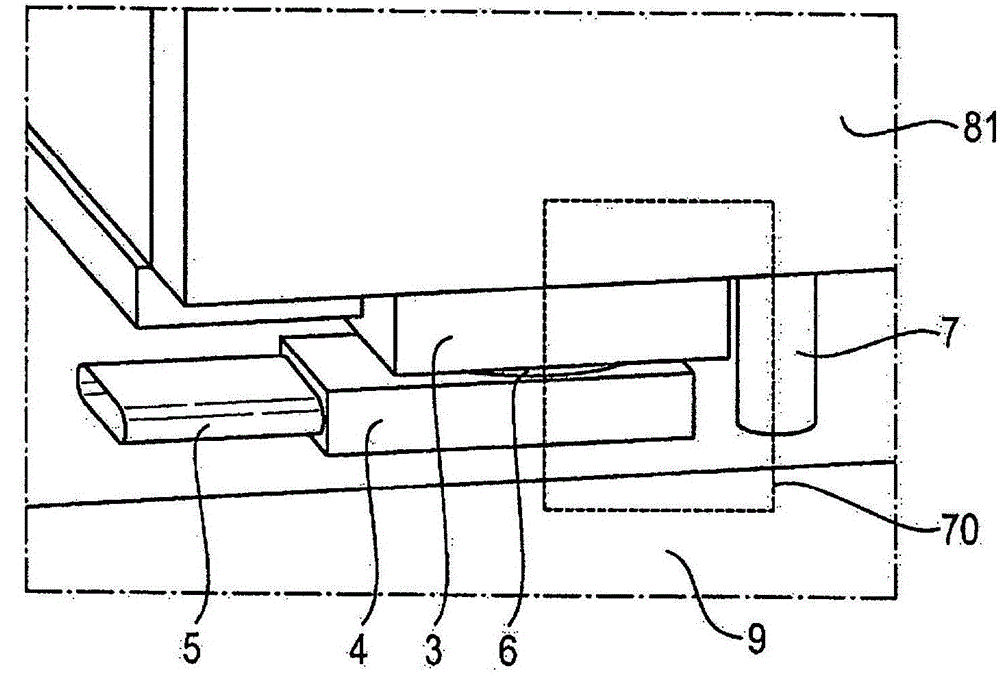

[0028] figure 1 A schematic diagram of a first embodiment of the cooling device 1 according to the invention is shown. The cooling device 1 has a cooling element 2 which can be formed, for example, as a plate. The cooling element 2 is used to receive and discharge the heat of the object 8 connected to the cooling element 2 (see figure 2 ). In addition, the cooling element 2 is connected to a first cooling connector 3, which forms an interface for leading out and / or introducing a cooling fluid. To this end, the first cooling connector 3 has an opening into which the pin 41 of the second cooling connector 4 can be embedded. The pin 41 is provided on the connecting part 40 of the second cooling connector 4 and can realize the transfer of the cooling fluid from the first cooling connector 3 to the second cooling connector 4. The cooling fluid can be, for example, a direct refrigerant or a water-glycol mixture. In order to prevent the cooling fluid from being discharged from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com